Elastic sheet manufacturing device

A technology for manufacturing devices and elastic sheets, applied in lamination devices, lamination auxiliary operations, chemical instruments and methods, etc., to achieve high molding accuracy, good molding effects, and good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

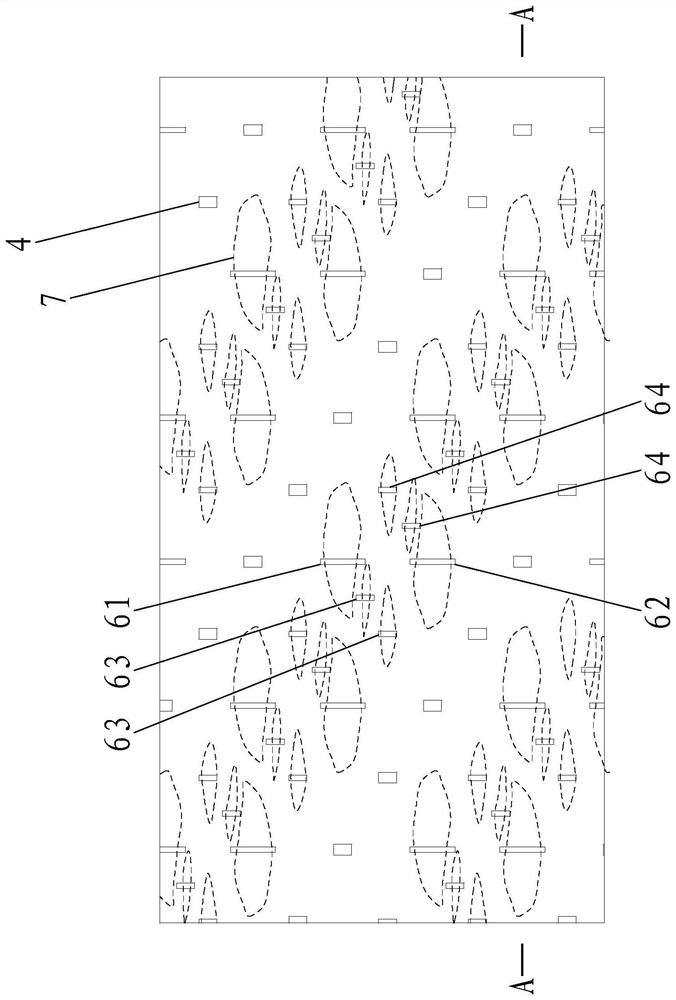

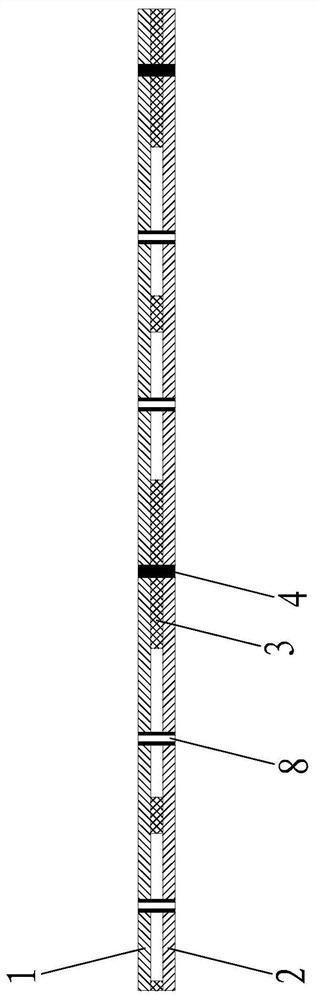

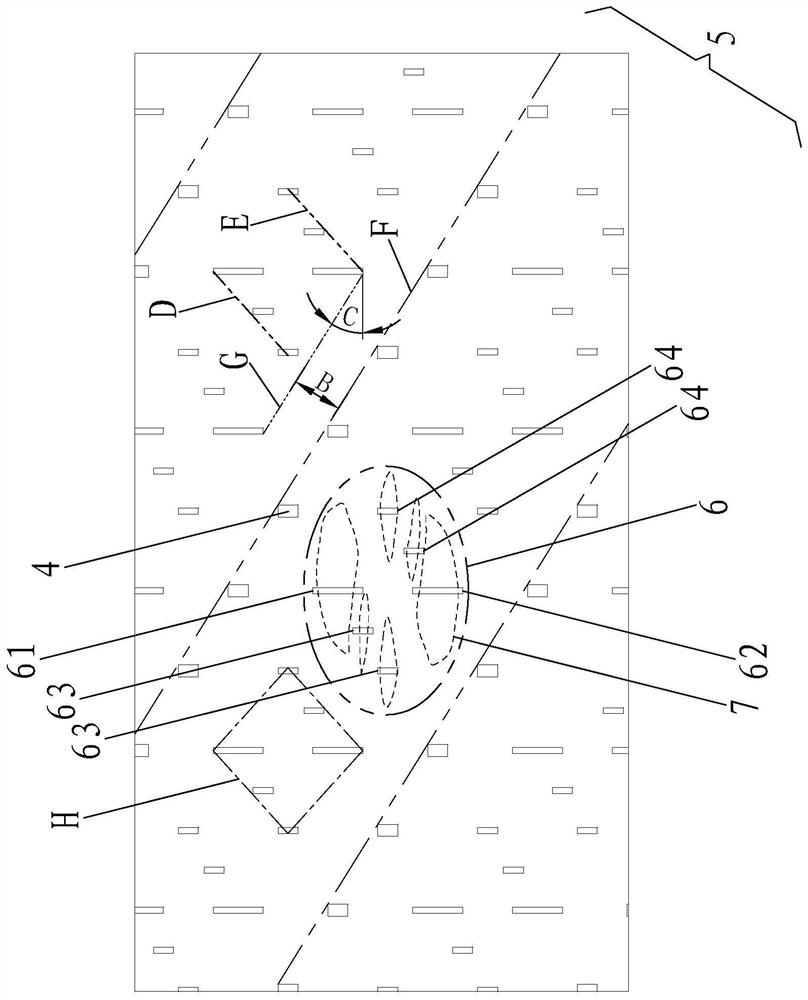

[0027] refer to Figure 1 to Figure 4, the present embodiment provides an elastic sheet, comprising an upper substrate 1, a lower substrate 2 and an elastic film 3 clamped between the upper substrate 1 and the lower substrate 2, the upper substrate 1, the lower substrate Material 2 is an air-permeable sheet material, and non-woven fabric material is selected in this scheme. The upper base material 1, the elastic film 3, and the lower base material 2 are fixed through a plurality of connecting parts to form fastening points 4, and each fastening point 4 is distributed to form a plurality of partition lines F, and each partition line F is spaced along the lateral direction. Set, two adjacent partition lines F form a partition area 5, there is at least one cutting unit 6 in the adjacent two partition lines, and each cutting unit 6 includes a strip-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com