Dryer system for high-strength high-modulus superhigh molecular weight polyethylene fibers

An ultra-high molecular weight, polyethylene fiber technology, applied in the field of dryer systems for high-strength and high-modulus ultra-high molecular weight polyethylene fibers, can solve the problems of wasting energy, affecting the post-stretching properties of fibers, and unable to reuse hot air, and improving the stretching Status, system pressure is easy, and the effect of maintaining stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

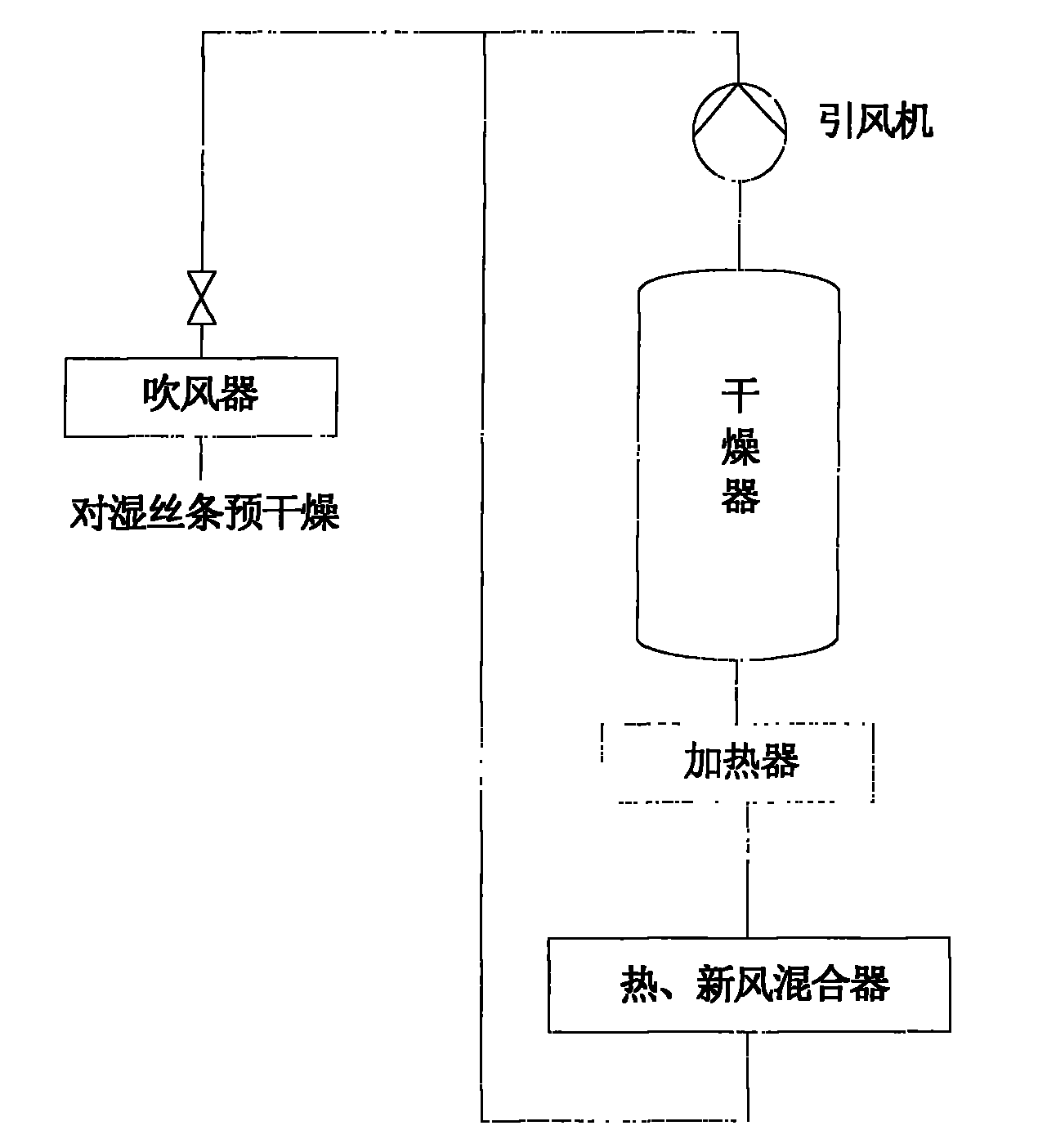

[0017] A dryer system for high-strength and high-modulus ultra-high molecular weight polyethylene fibers of the present invention, its structural schematic diagram can be seen figure 1 , comprising a mixer, a heater, a dryer, an induced draft fan and a blower, the mixer, a heater, a dryer and an induced draft fan are connected in sequence and form a circuit, and the blower is respectively connected with the induced draft fan and the induced draft fan through a valve The mixer is connected. Air discharge into the blower is 10-30%.

[0018] The active rollers in the dryer are fixed on both sides. After the air is mixed by the mixer, it enters the heater to be heated again, and then it is reintroduced into the dryer by the induced phoenix fan for recycling. The wet filaments are pre-dried, and the remaining hot air is mixed with fresh dry air and reheated by the heater, and the above-mentioned route is circulated.

Embodiment 2

[0020] Under the same output and the same weather conditions, a comparison test was carried out for direct discharge of all hot air and 10% of hot air. The comparison results are shown in Table 1:

[0021] Table 1

[0022] category

[0023] From the above table, it can be obtained that after most of the return air is recycled, the liquid content of the yarn output from the dryer is significantly reduced, and the energy saving effect is remarkable.

Embodiment 3

[0025] Under the same output, the same draw ratio, and the same draw speed, a comparison test was carried out for direct discharge of all hot air and 10% of hot air. The comparison results are shown in Table 1:

[0026] Table 2

[0027] category

[0028] It can be obtained from the above table: when all the hot air is discharged in a straight line, the yarn at the inlet of the dryer contains a large amount of liquid, and the volatilization of the liquid will cause the yarn to shrink, generate tension, and easily produce fuzz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com