Anti-reverse-warping shading adhesive tape capable of being removed through stretching and preparation method of anti-reverse-warping shading adhesive tape

A shading tape and removal technology, applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problems of poor anti-warping ability and difficult removal of shading tapes. Good fit and stress relief properties, improved anti-warpage, high tension effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

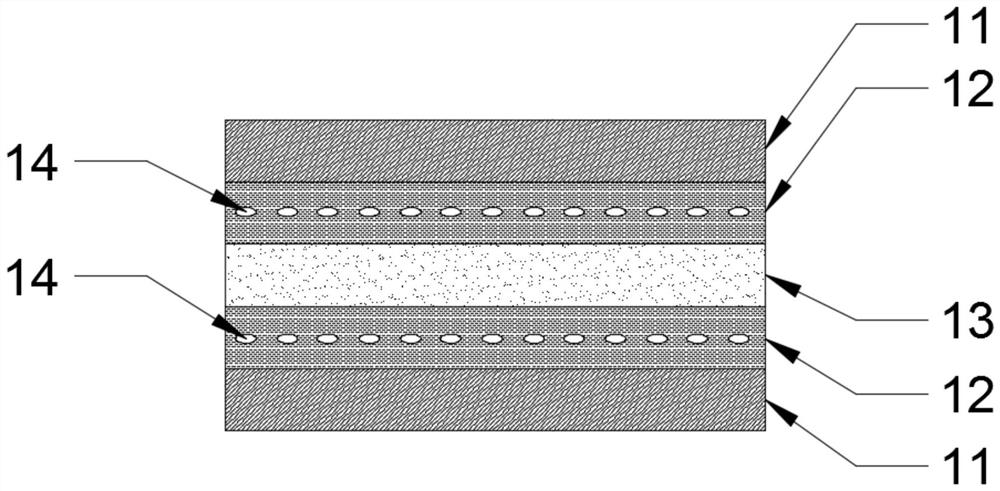

[0039] see figure 1 As shown, an anti-warping and removable light-shielding adhesive tape includes a black base material layer 13, and the black base material layer 13 preferably uses a TPU film as a base material, and the upper and lower sides of the black base material layer 13 Both are provided with an acrylic glue layer 12, and the acrylic glue layer 12 is provided with a release layer 11 on the side away from the black substrate layer 13, and the release layer 11 is a release film or release paper.

[0040] In this embodiment, the black substrate layer 13 is black, and its light transmittance is 0%; the thickness of the black substrate layer 13 is 20 μm-50 μm, the tensile strength is 12Mpa-17Mpa, and the elongation at break is 500%-800%.

[0041] In this embodiment, the thickness of the acrylic glue layer 12 is 10 μm-30 μm, and the peeling force is 1300 g / in-1700 g / in; several microspheres 14 are added in the acrylic glue layer 12, and the microspheres 14 are glass Micro...

Embodiment 2

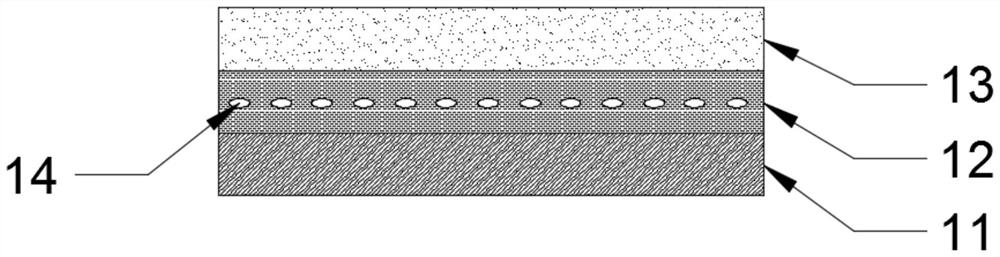

[0051] see figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the light-shielding tape is a single-sided light-shielding tape, including a black base material layer 13, and an acrylic glue layer 12 is provided on the upper or lower side of the black base material layer 13, and the acrylic The glue layer 12 is provided with a release layer 11 on a side away from the black base material layer 13, and the release layer 11 is a release film or a release paper. In this embodiment, the black base material layer 13 is made of black TPU material, and its light transmittance is 0%; the thickness of the black base material layer 13 is 20 μm-50 μm, the tensile strength is 12Mpa-17Mpa, and the elongation at break is 500%- 800%.

[0052] In this embodiment, the thickness of the acrylic glue layer 12 is 10 μm-30 μm, and the peeling force is 1300 g / in-1700 g / in; several microspheres 14 are added in the acrylic glue layer 12, and the microspheres 14 are glass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com