Water-based degradable plastic-replacing gloss oil and preparation method thereof

A water-based, light-shaping technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of non-degradability and increased environmental burden, and achieve the effects of good gloss, excellent tension, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

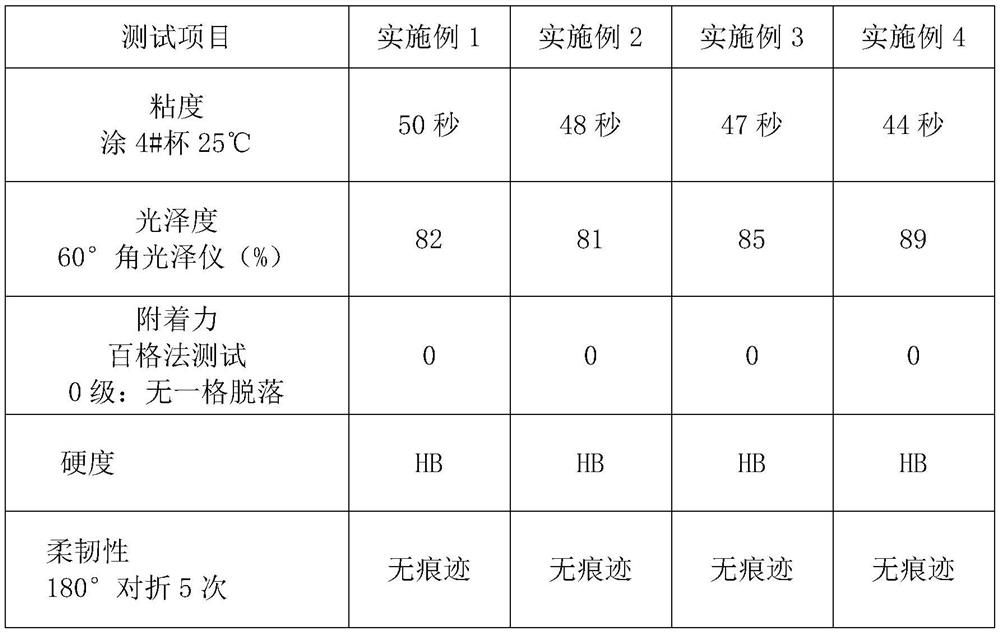

Examples

Embodiment 1-4

[0023] A preparation method of water-based degradable plastic varnish, comprising the following steps:

[0024] Step 1: Prepare each raw material according to the weight percentage of Table 1, put water-based polyurethane resin, deionized water, and water-based film-forming aid into the container, open the stirrer and stir, the stirring time is 20 minutes, the stirring rate of the stirrer 500-800 rpm, the stirring condition is 25-35°C, and the pressure is normal pressure;

[0025] Step 2: Slowly add wetting and leveling agent, polytetrafluoroethylene wax, and associative thickener in the completed step 1 process, and start the agitator for mixing and stirring. The stirring time is 5 minutes. The agitator The stirring speed is 800 rpm, and the stirring condition is normal temperature and normal pressure;

[0026] Step 3: After the operation of step 2, filter with 150-mesh mesh, and pack it after passing the test.

[0027] A kind of application of water-based degradable plasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com