Machine vision based fabric pattern adjustment method and device thereof

A machine vision and fabric technology, applied in the inspection of textiles, papermaking, textile materials, etc., can solve the problems of unable to maintain the fabric pattern in a standard state, low production efficiency, and failure to satisfy customers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

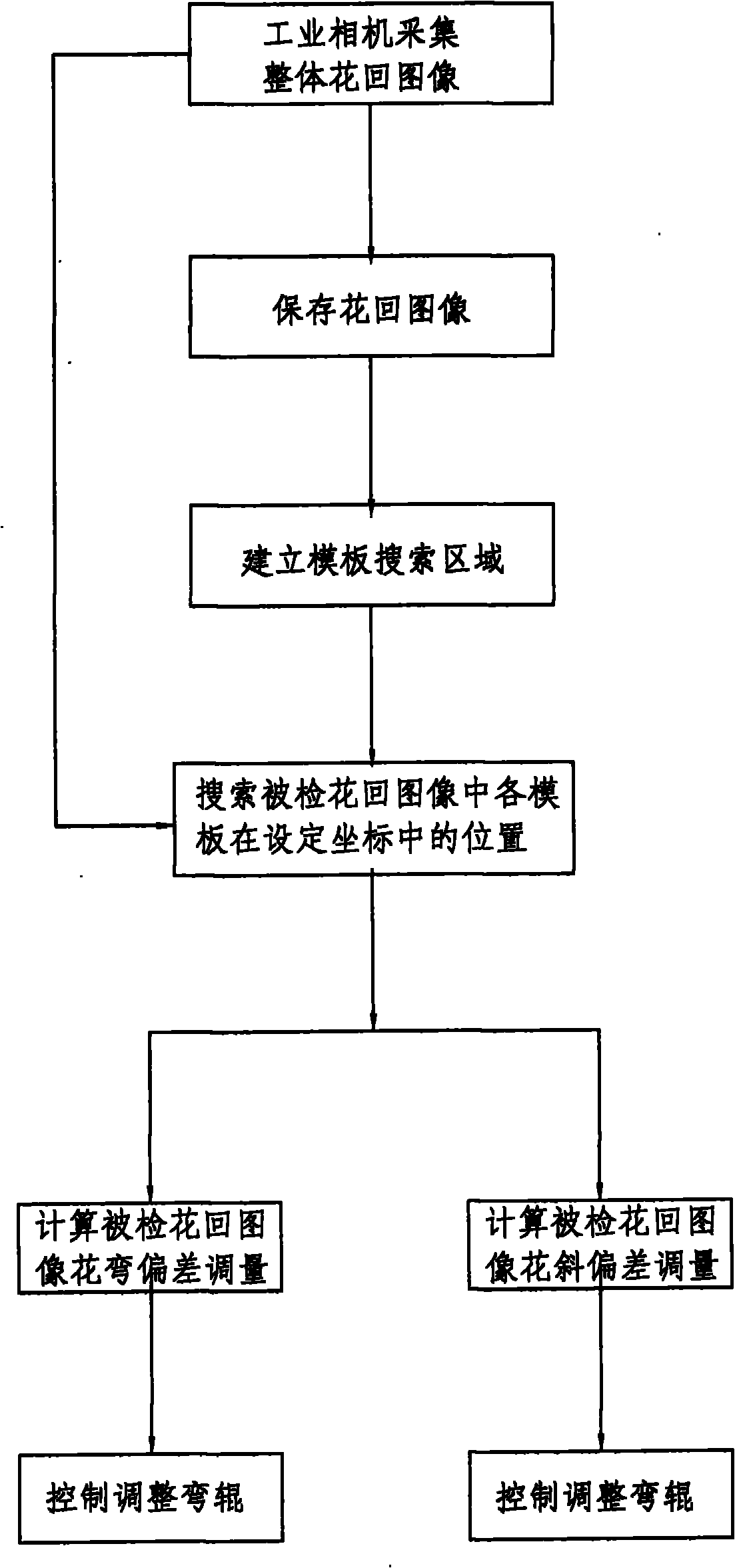

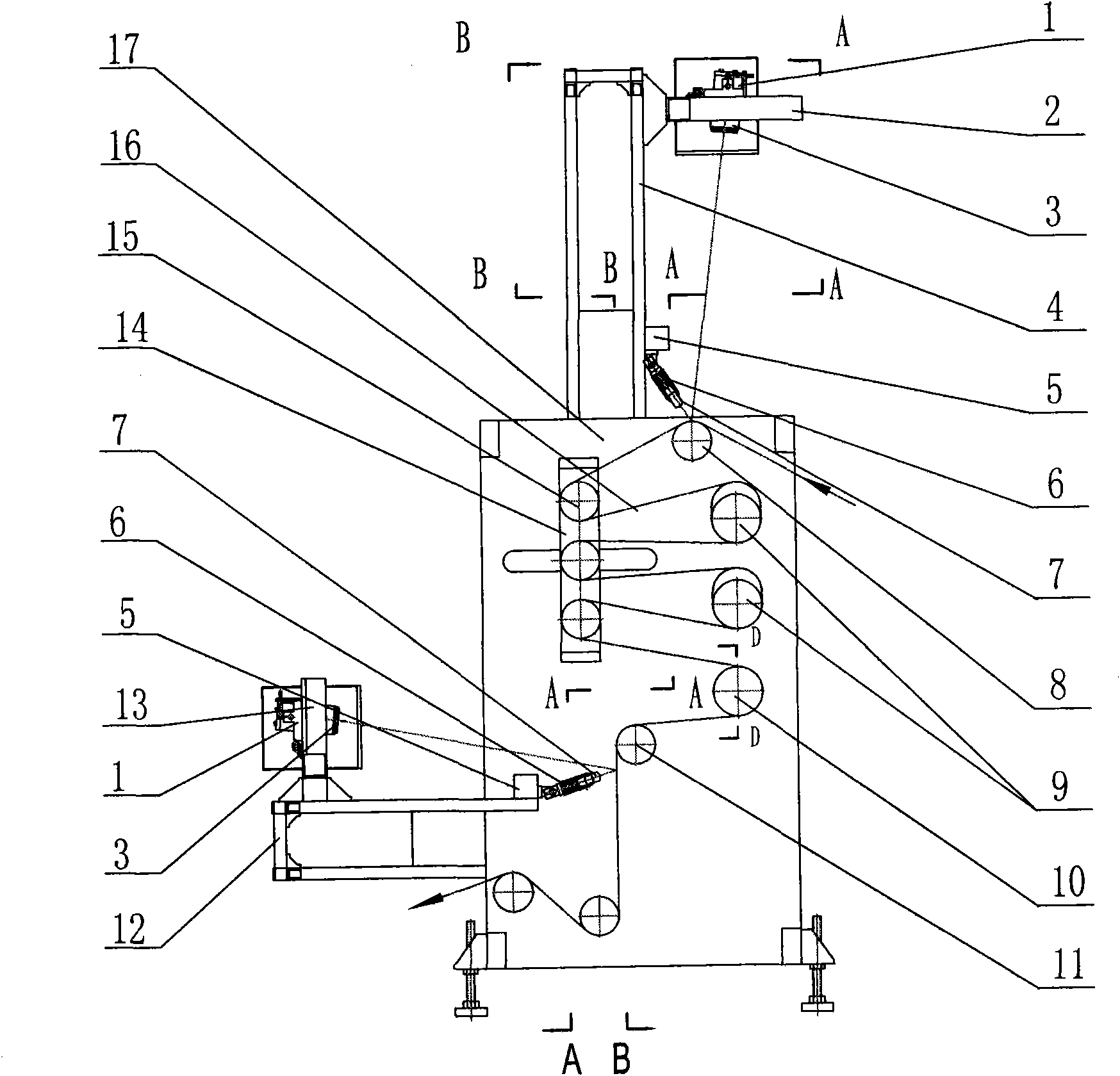

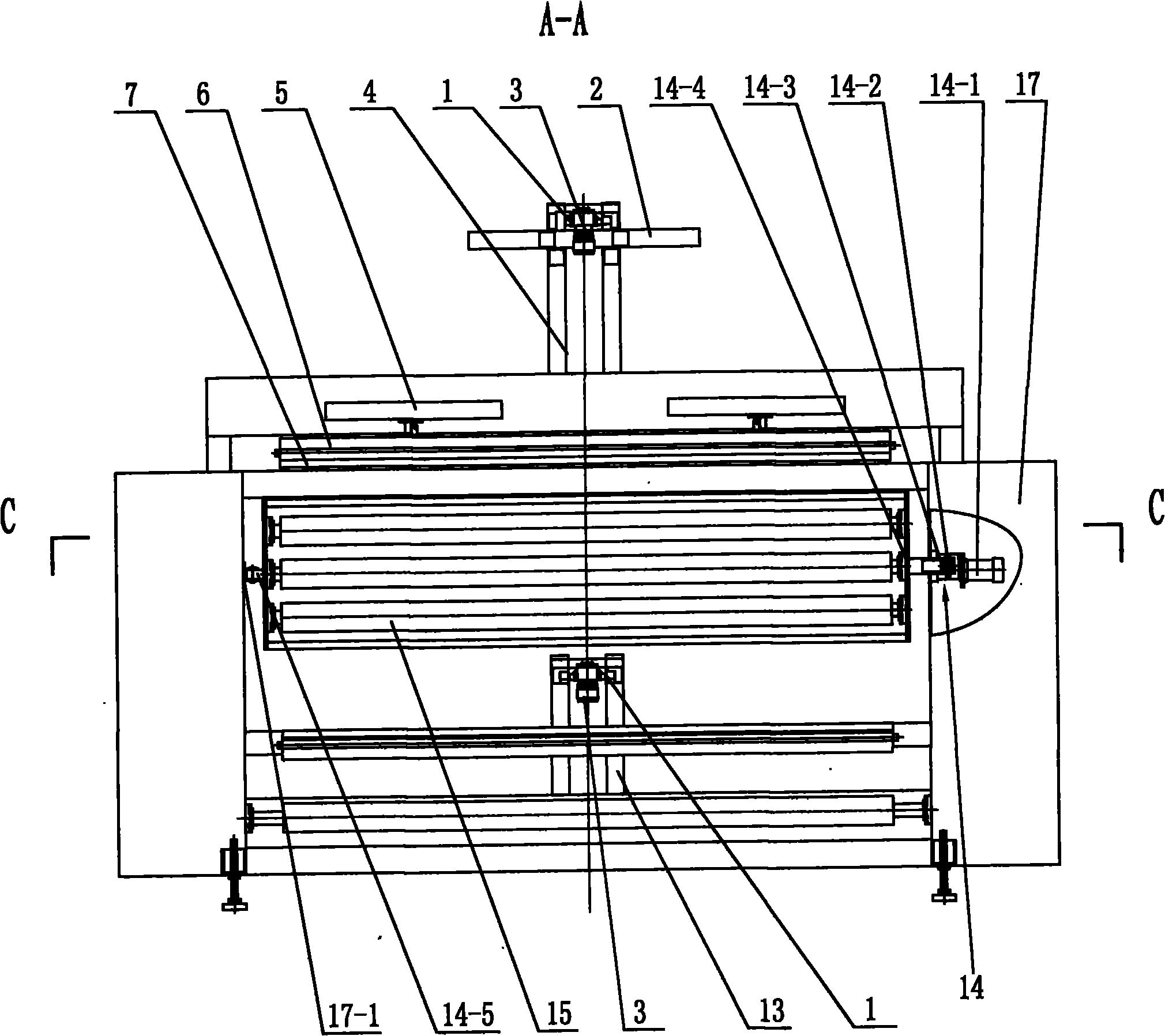

[0018] See figure 1 As shown, the machine vision-based fabric automatic flower finishing method of the present invention first collects at least one whole flower back image in the online moving fabric through an industrial camera, loads the flower back image into the central processing unit, and the flower back image is processed in the callback function In the conversion of the pattern image data format and save the pattern image, this industrial camera is a line array camera that can collect fabric pattern images, such as CCD line array camera, the resolution is ≥0.5K, the line frequency is ≥2K, according The size of the returned image can set parameters such as the height, width, exposure time and trigger mode of the image of the industrial camera. Through the interactive interface of the central processing unit, arbitrarily select two or more areas in the above-mentioned floral image as templates, and the areas of each template of the selected floral image are areas with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com