Eccentric butterfly valve

An eccentric butterfly valve, eccentric technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problem of increased valve additional cost, achieve reasonable valve opening and closing torque, improve sealing specific pressure, and reduce wear effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

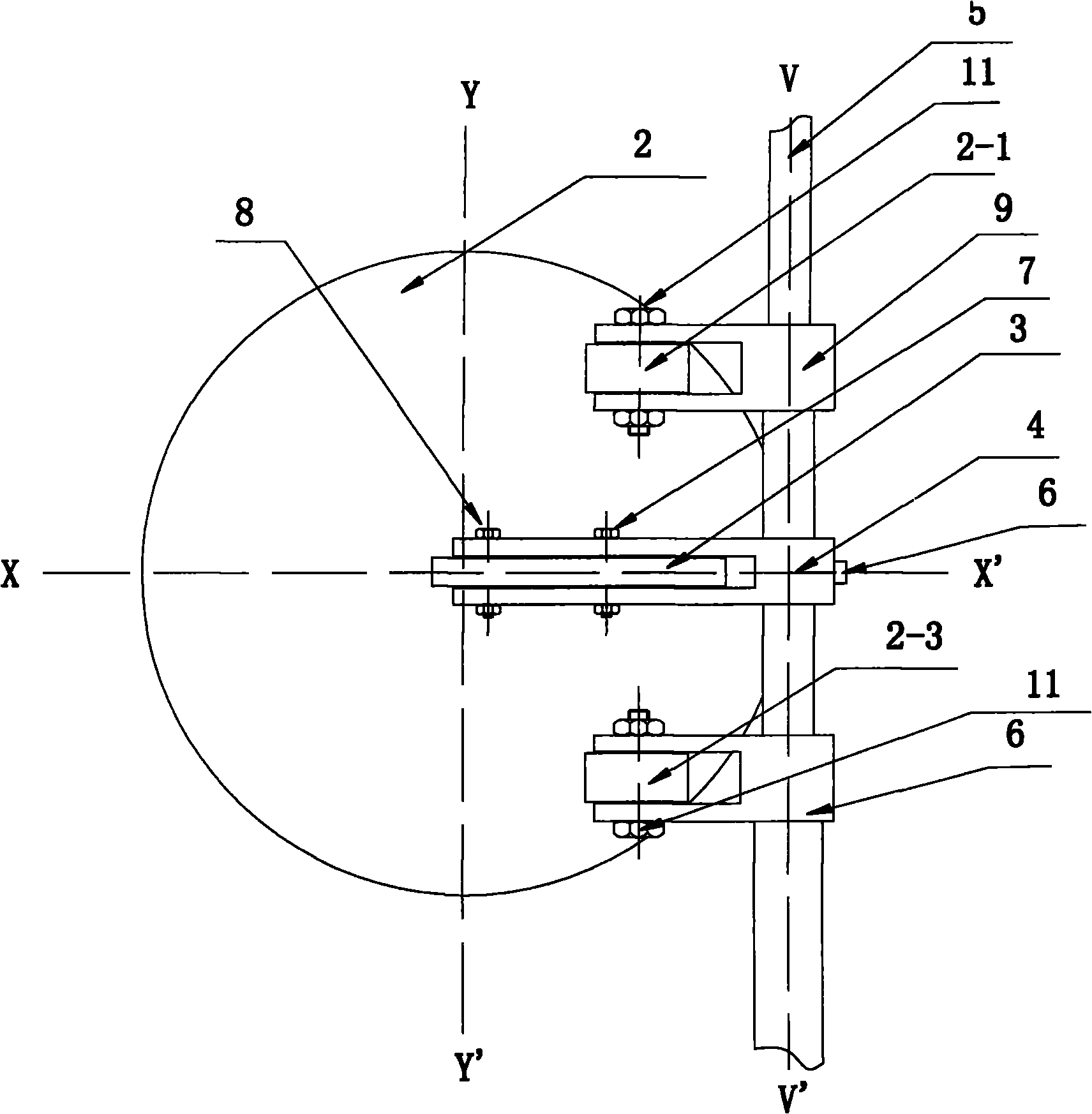

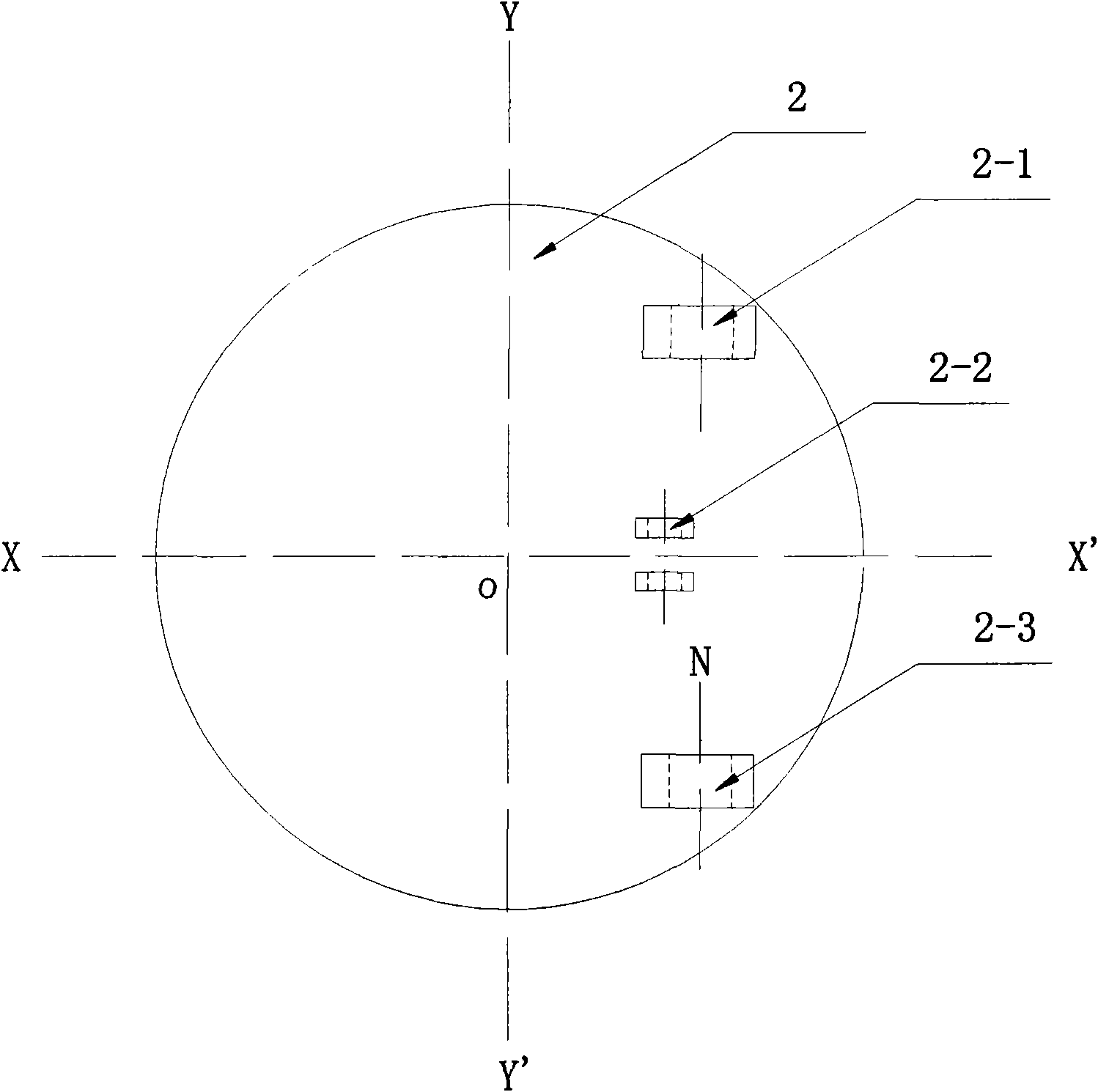

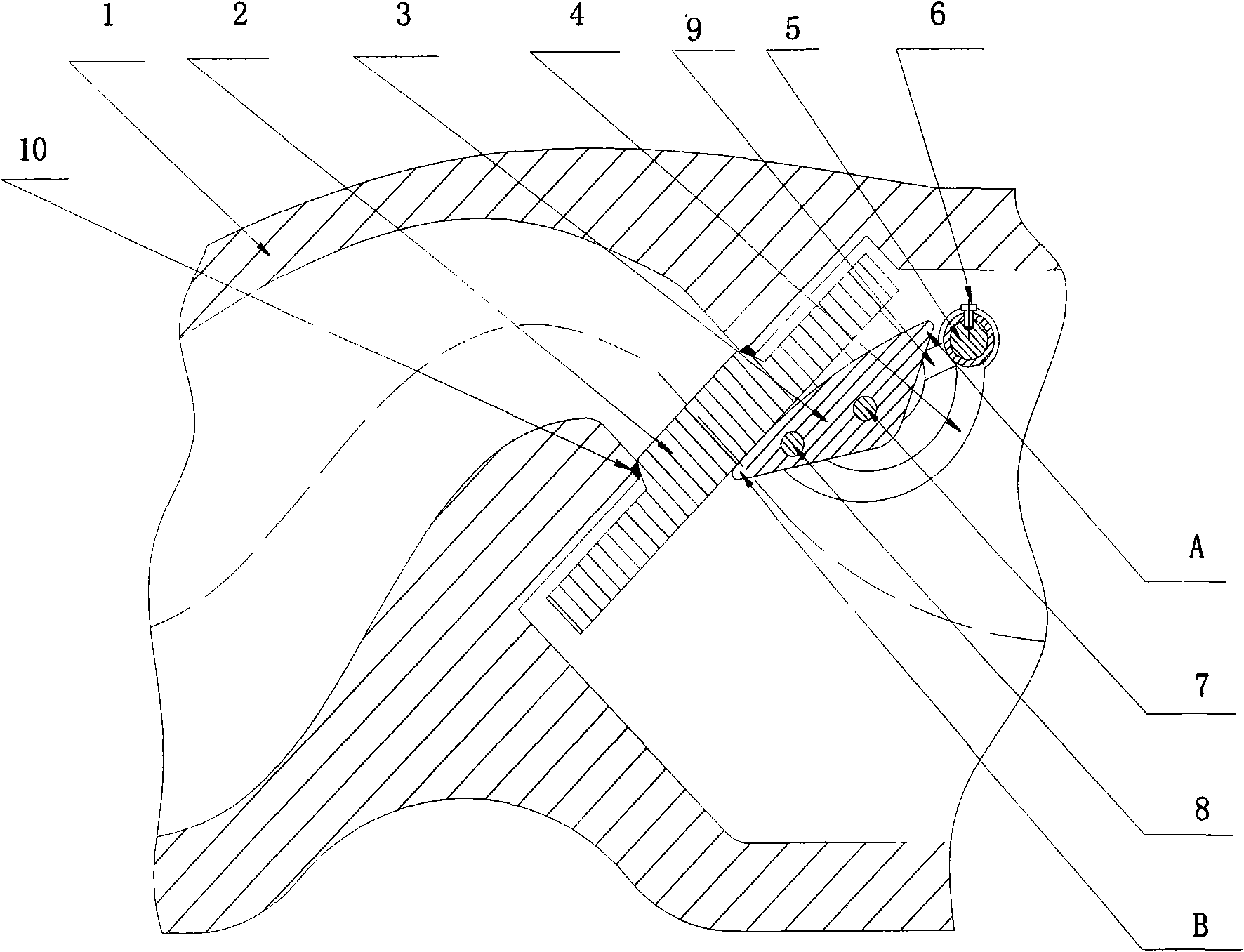

[0010] Such as figure 1 , 2 , 3, and 4, the eccentric butterfly valve includes a valve body 1, which is characterized in that it also includes: the eccentric butterfly plate 2 with a spherical sealing surface inside the valve body 1 and the corresponding spherical The valve seat 10 on the sealing surface, the eccentric butterfly plate 2 is installed on the valve stem 5 through the connecting rod 9, and the back of the eccentric butterfly plate 2 is provided with an eccentric adjustment block 3, and the eccentric adjustment block 3 moves the shaft nail 8 and the arc through the eccentric adjustment block. The connecting rods 4 are connected, and the arc-shaped connecting rods 4 are fixedly installed on the valve stem 5 through the positioning pin 6 .

[0011] The back of the eccentric butterfly plate 2 is provided with a first fixed block 2-1, a second fixed block 2-2, and a third fixed block 2-3, and the connecting rod 9 passes through the shaft nail 11 and the first fixed bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com