Method for testing screen line number and screen angle for printed matter

A technology of screen line number and screen angle, applied in screen printing, printing, printing plate preparation, etc., can solve the problems of low degree of automation and low precision, and achieve the effect of high degree of automation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

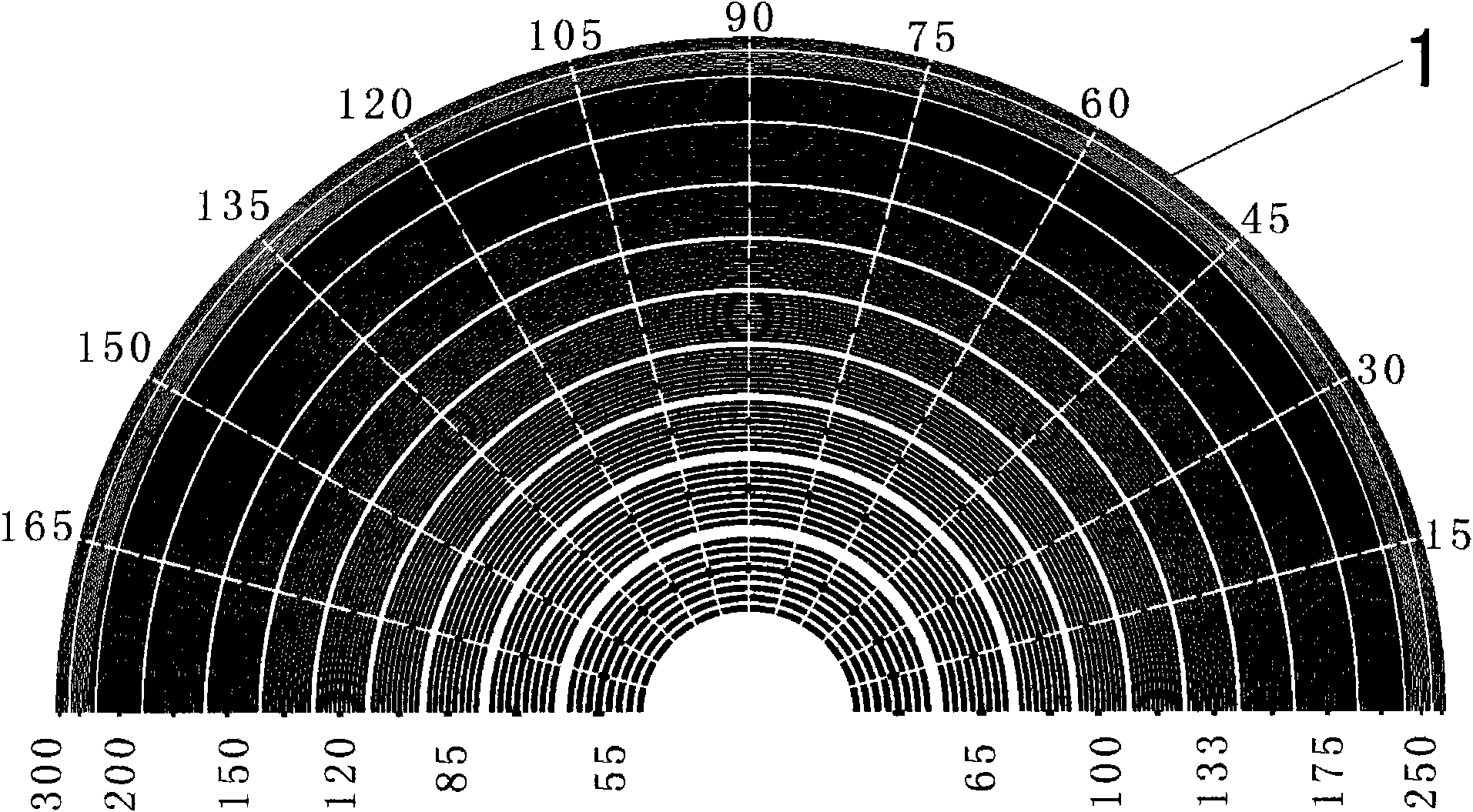

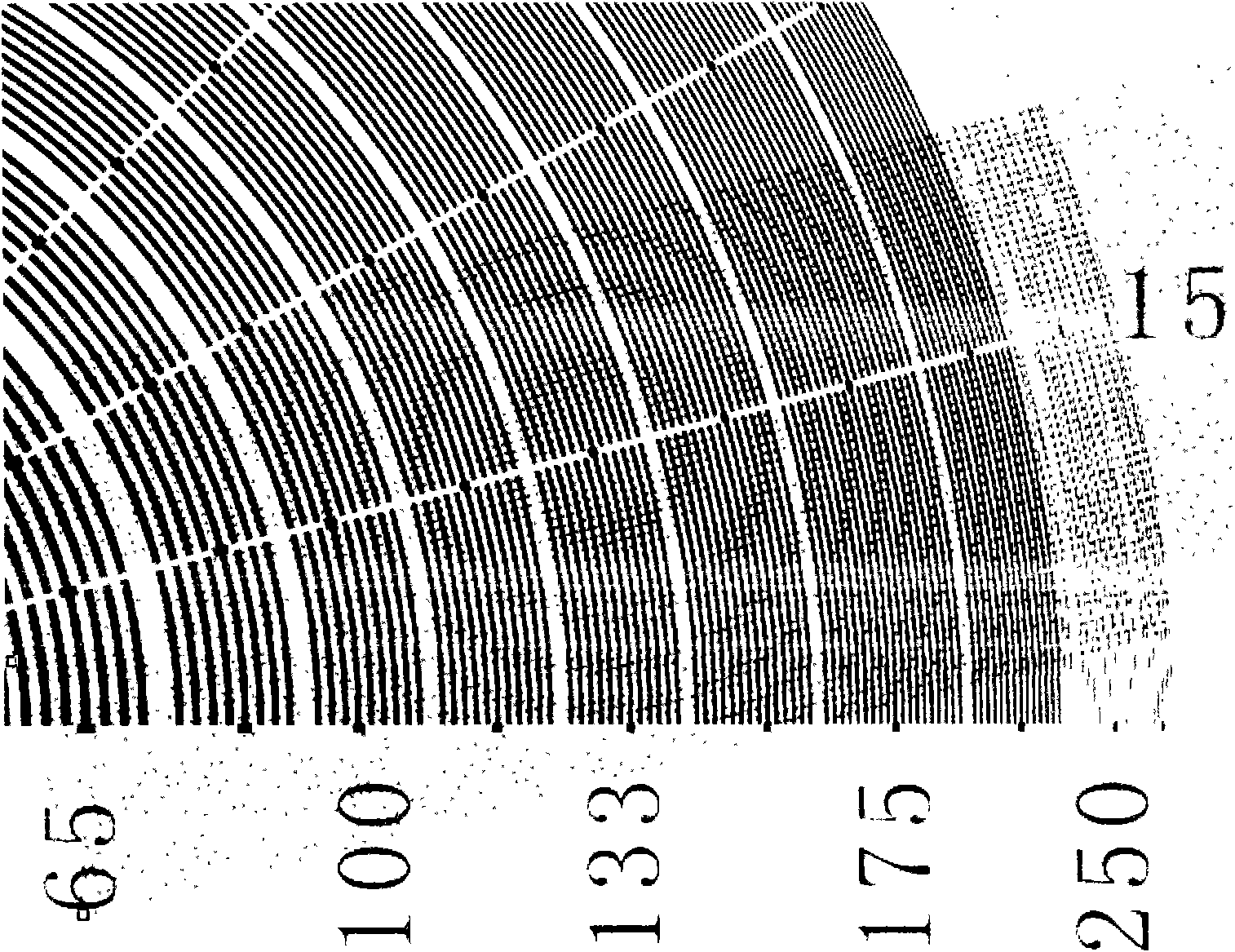

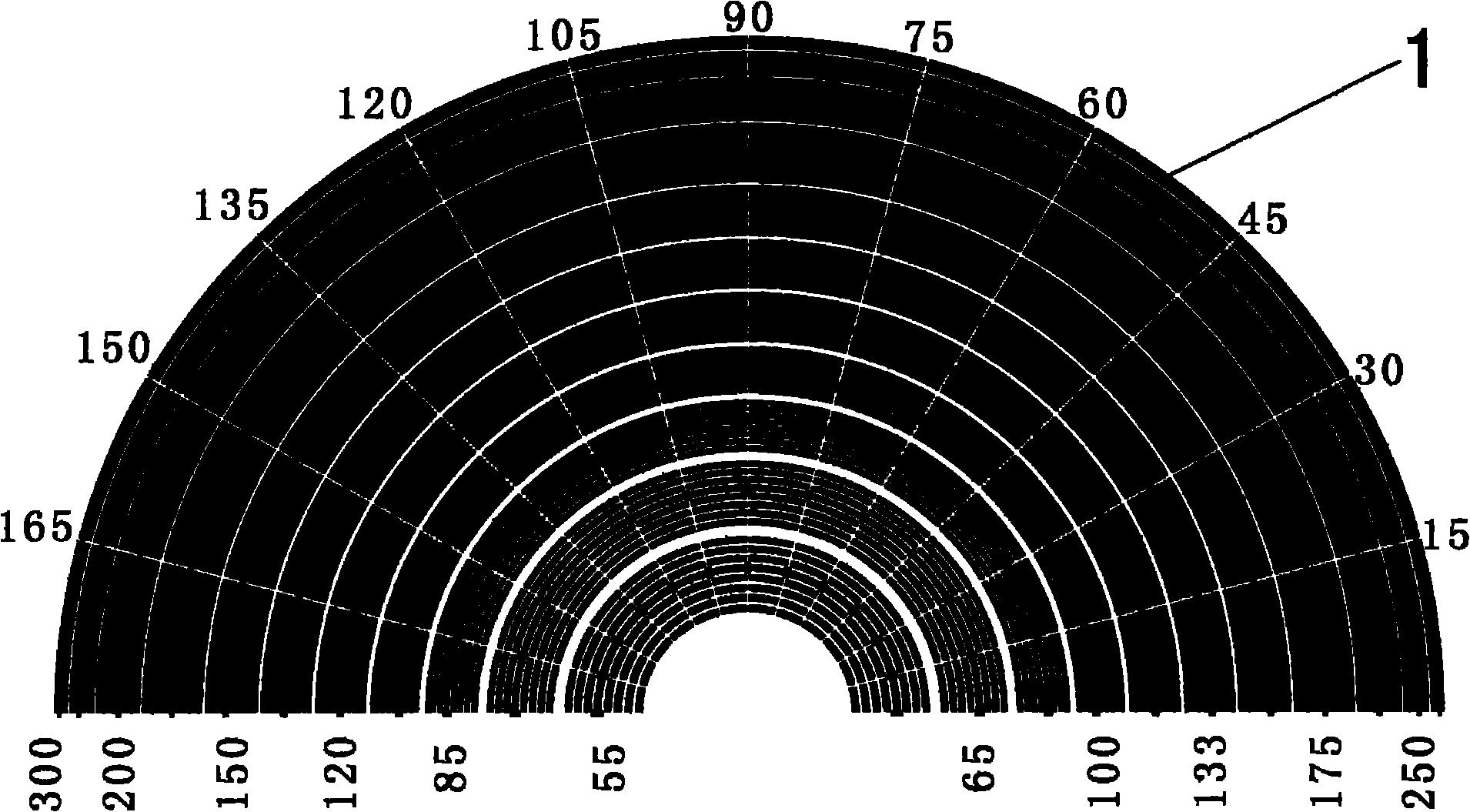

[0045] Step 1: Select the number of screen lines to be 175 lines / inch, divide according to the interval of 1dpi, and divide into 165-185 screen levels. Calculate the line width / 2=0.0726mm of 175 / dpi; line width / 3=0.0484mm, as shown in Table 1. Set the line width that matches the output points of the laser imagesetter=4 / dpi; as shown in Table 1, taking 175 lines as an example, then R=H 3 +C 3 +(C 4 / 2)-(C 3 / 2) (wherein R=22.0940mm; H3=21.9480mm; C3=0.1460mm; C4=0.145mml store the data and calculate, draw the circle, according to this method, draw 165-185 lines / inch in the same way The concentric circles.Using the Moiré fringe principle formula, the number of screen lines in the same set of printing plates is the same, so the formula can be transformed into When the included angle is smaller, the included angle is close to 0° for the network ruler algorithm. At this time, the moiré spacing is larger, which exceeds the resolution of the human eye. At this time, the human eye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com