Accumulator

A technology of accumulator and bellows, applied in the direction of accumulator device, actuator accumulator, fluid pressure actuating device, etc., can solve the problem of inability to ensure the expansion and contraction stroke of the bellows, achieve smooth relative movement and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] Embodiments of the present invention will be described below with reference to the drawings.

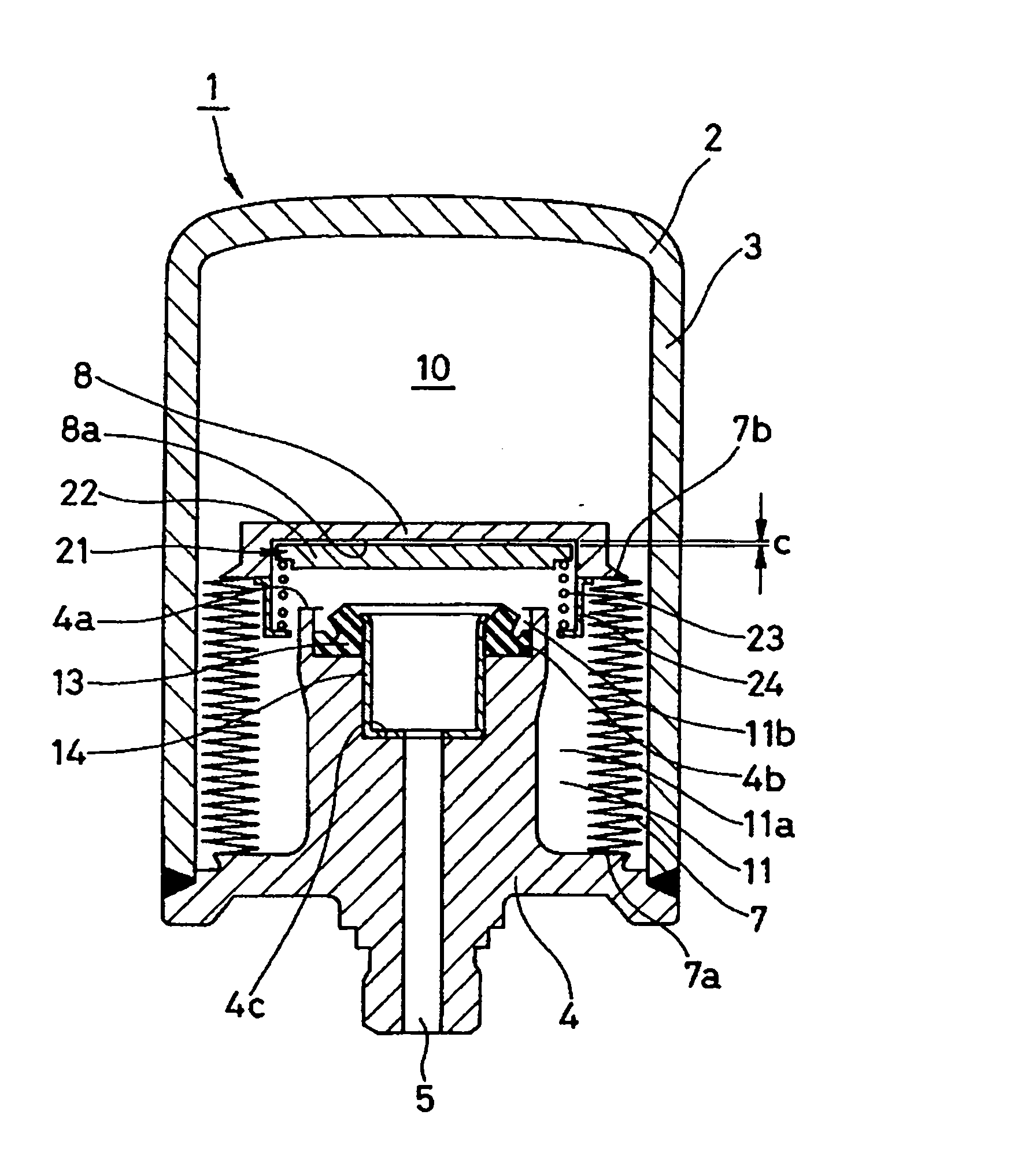

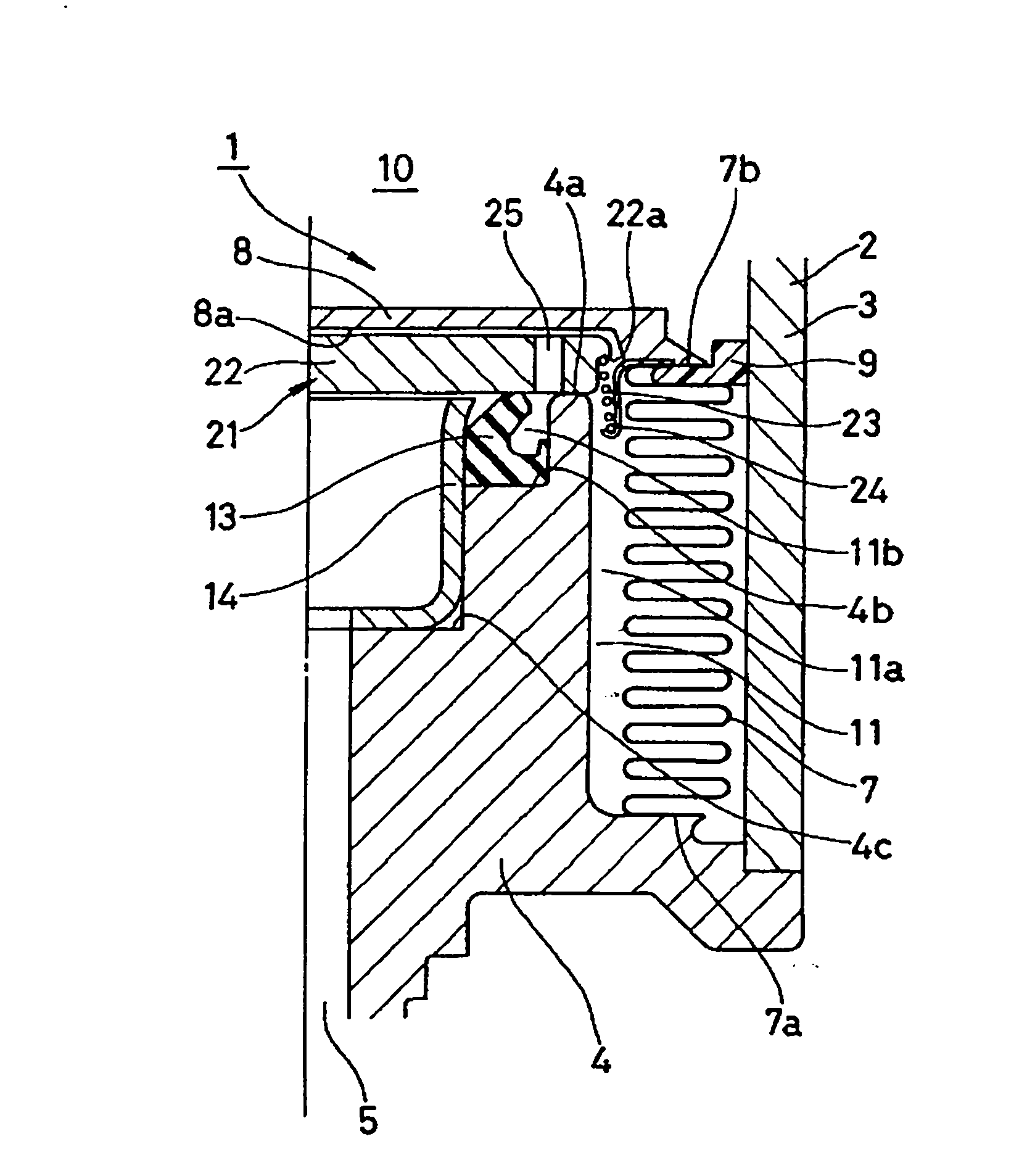

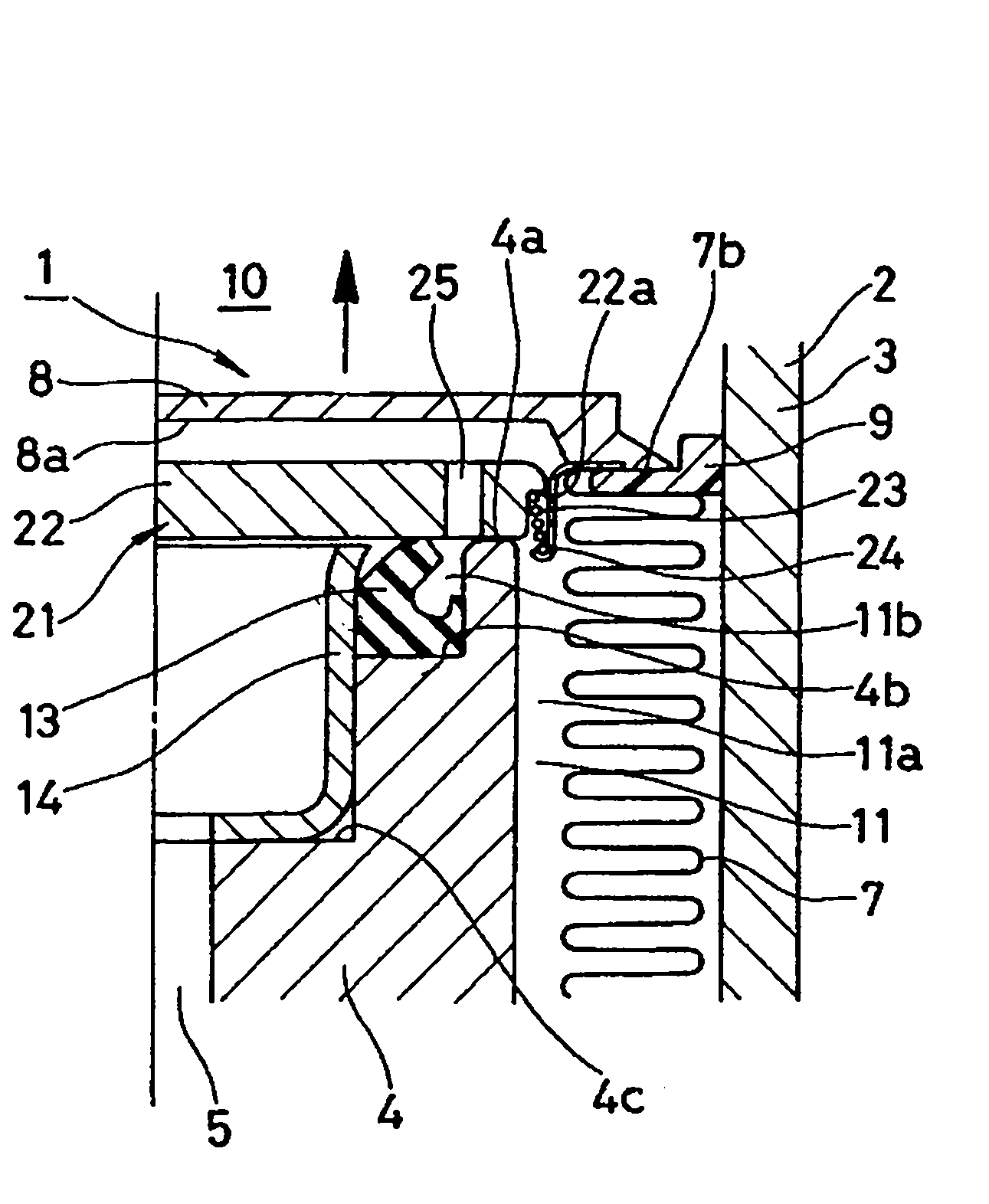

[0078] Figure 1 to Figure 3 A full cross-section and a partial cross-section of the accumulator 1 according to the embodiment of the invention are shown. figure 1 , figure 2 , image 3 The states during normal operation, zero drop, and thermal expansion in the zero drop state are shown, respectively.

[0079] The accumulator 1 of the present embodiment is a metal bellows type accumulator using a metal bellows as the bellows 7, and is configured as follows.

[0080] That is, first, an accumulator case 2 having an oil passage 4 connected to a pressure pipe (not shown) is provided, and a bellows 7 is arranged inside the case 2 to separate the inner space of the case 2 into a gas chamber in which high-pressure gas is enclosed. The chamber 10 communicates with the liquid chamber 11 of the passage hole 5 of the oil passage 4 . The casing 2 is formed by combining a bottomed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com