Heating system for double-ovenized oscillator on single printed circuit board

A technology of printed circuit boards and oscillators, which is applied in the field of heating systems of double-furnace oscillators, and can solve the problems of complex manufacturing of the system, complicated and expensive housing efforts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

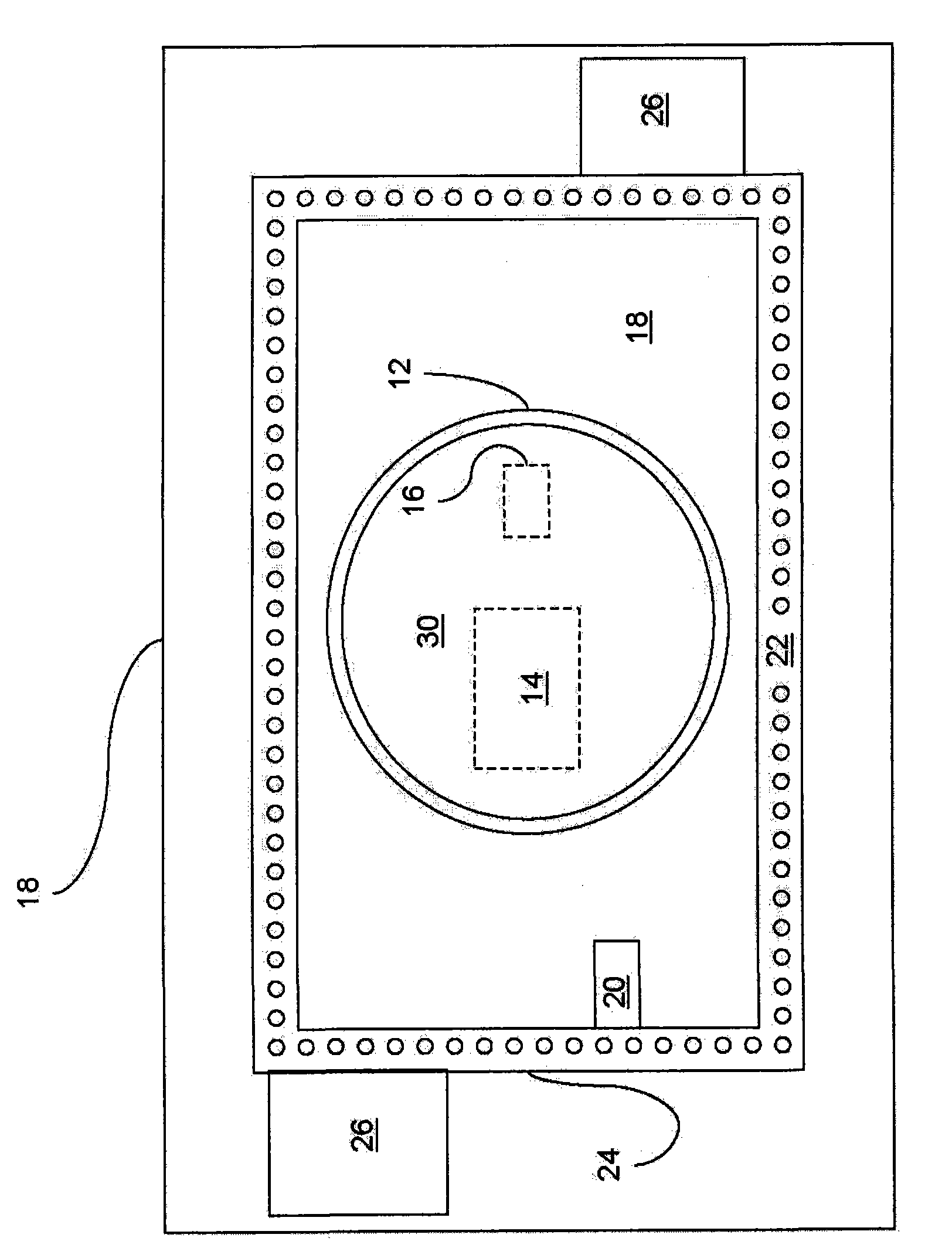

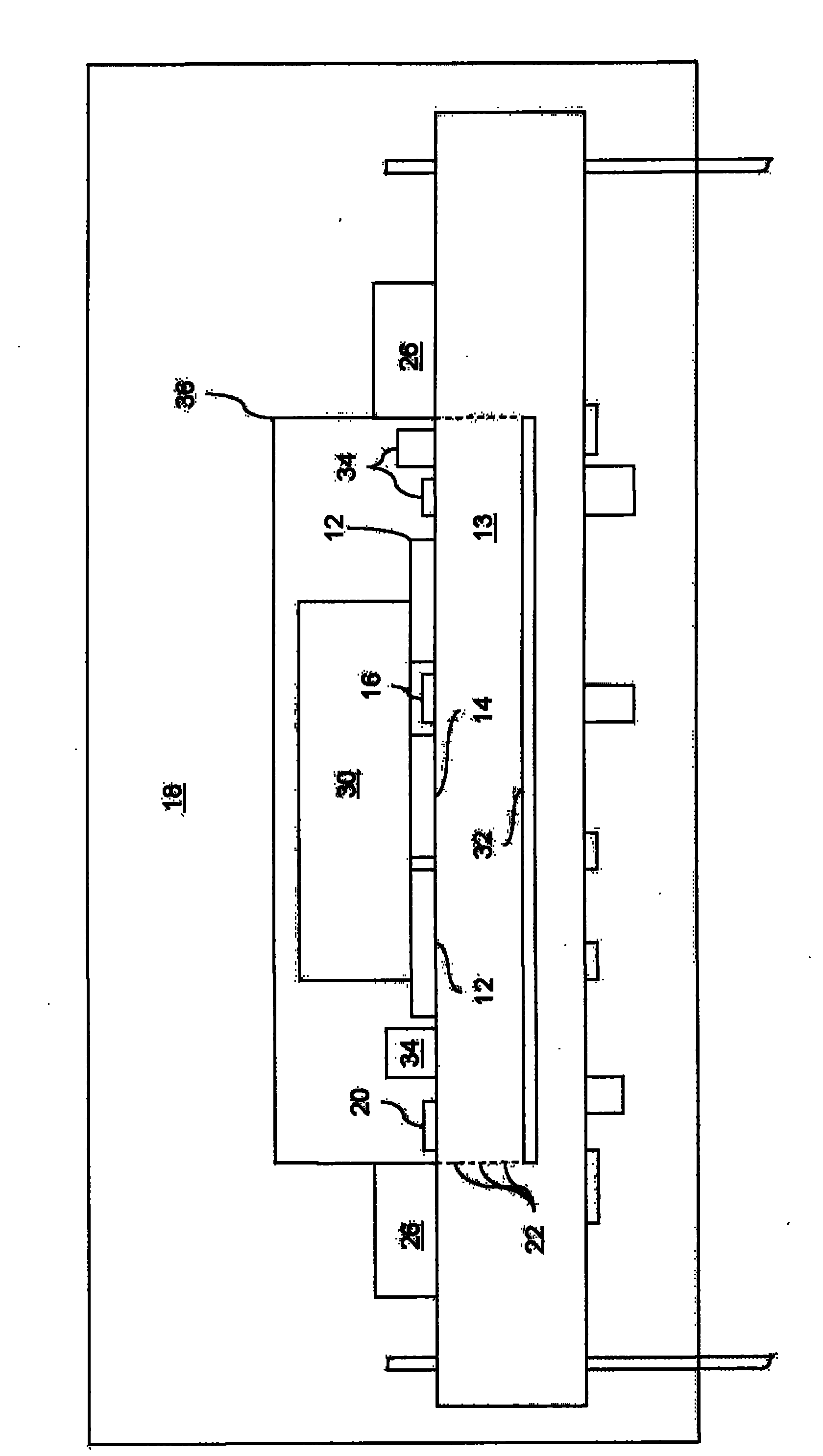

Image

Examples

Embodiment 1

[0033] A unit designed with the idea of two ovens (twin oven) has been tested. The unit so tested included the board assembly housed in a C0-8 eurocase enclosure. The crystal used was a third overtone 5 MHz SC in a HC-37 / U holder.

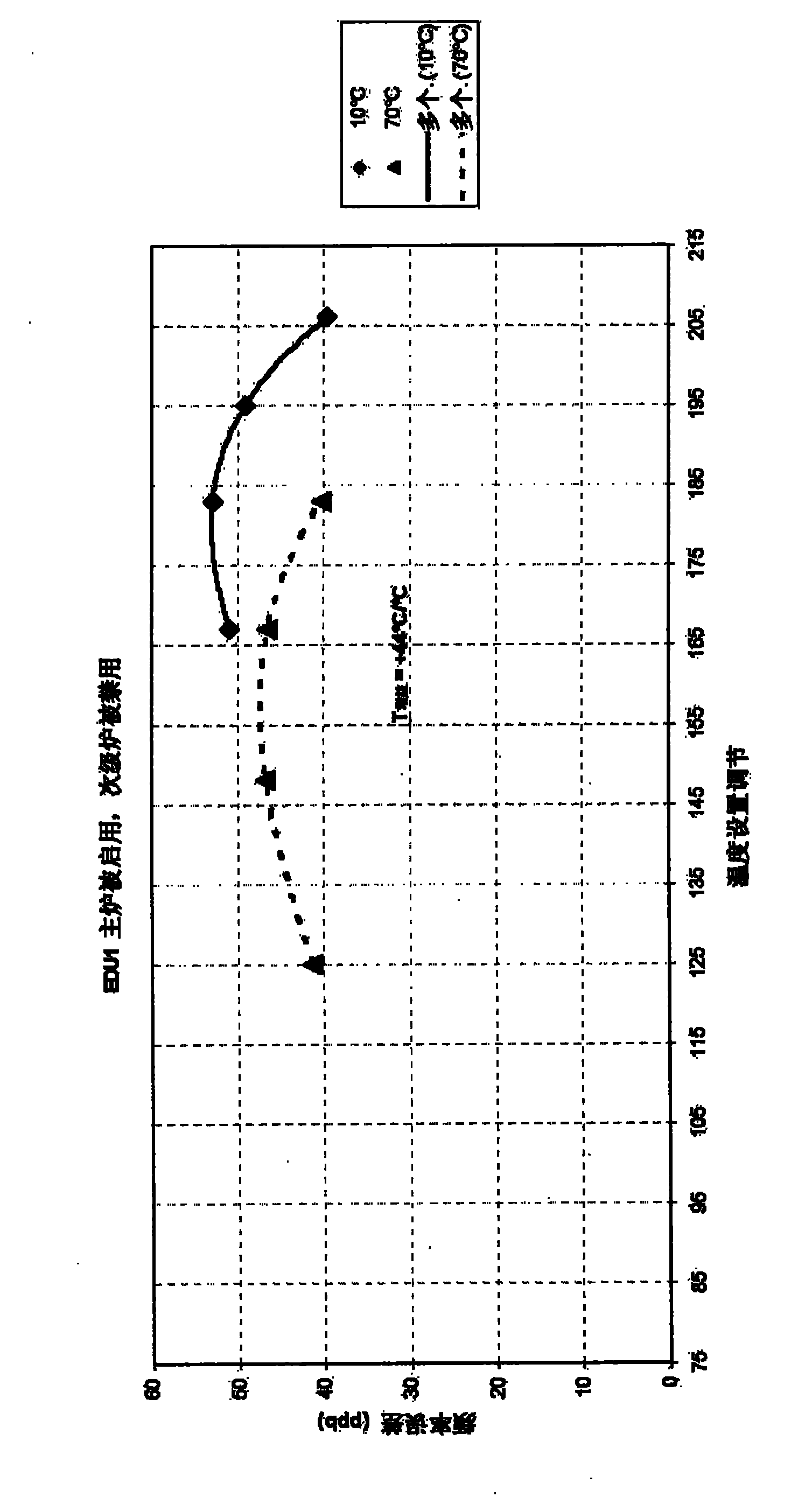

[0034] A temperature analysis with the primary (inner) furnace enabled and the secondary (outer) furnace disabled as in image 3 shown. As shown, tests of the design are provided at 10°C, 35°C and 70°C. The temperature analysis results were compared with Figure 4 Compared with the temperature analysis results shown, where Figure 4 Is the case where the primary furnace is disabled and the secondary furnace is enabled. In both cases, the heat gain at the crystal is comparable to that of a standard single furnace Euro-type OCXO.

[0035] Figure 5The thermal analysis shown shows the performance when both furnaces are activated. It can be noticed that at the crystal, the heat gain increases dramatically, while the change in the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com