Suspension device for chemical reaction kettle

A technology of chemical reaction kettle and suspension device, applied in chemical instruments and methods, chemical/physical process, chemical/physical/physical-chemical process, etc. The effect of chemical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

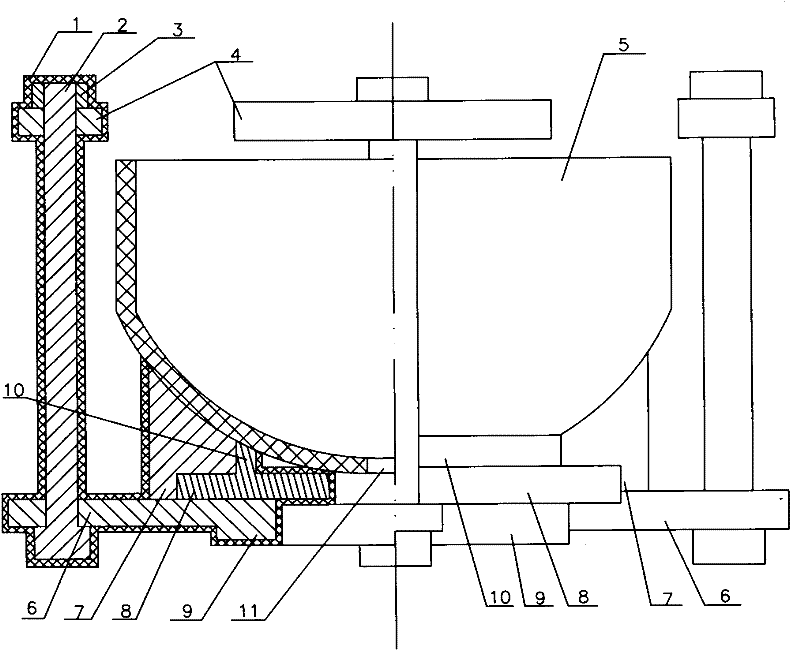

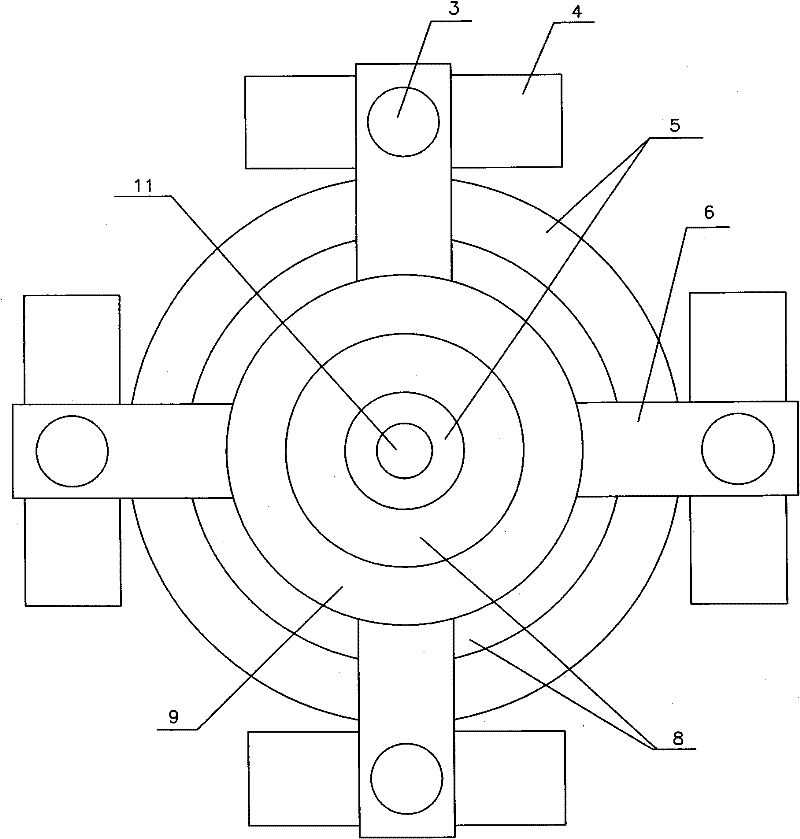

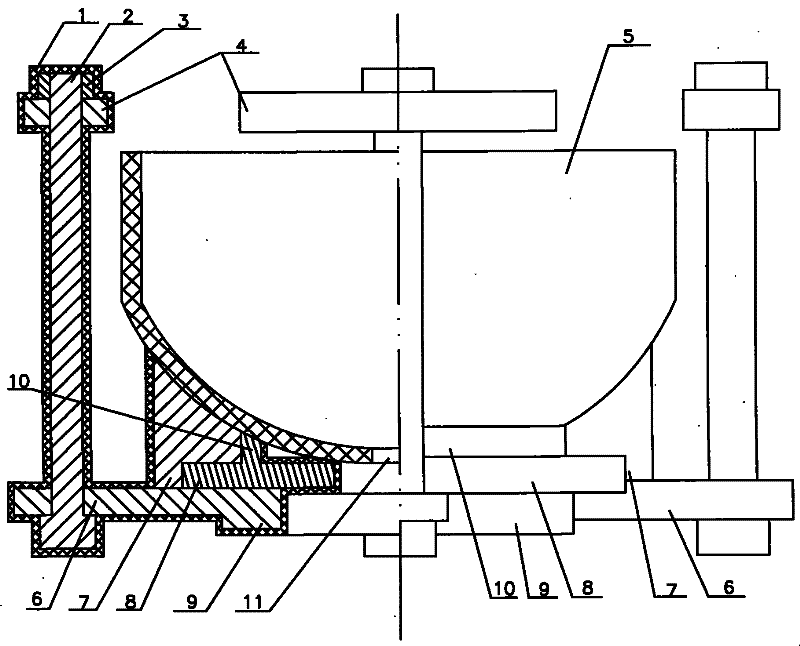

[0014] exist figure 1 , figure 2 In the shown embodiment, the circular supporting ring 9 and the four crossbeams 6 are an integral body, and the outer ends of the four crossbeams 6 have round holes, and the four crossbeams 6 are respectively sleeved on the four round rods 2 through the round holes on the crossbeams 6. Above, the upper ends of the four round rods 2 respectively pass through the round holes on the four horizontal plates 4 to be connected with the nuts 3, and the two ends of the four horizontal plates 4 are hung on the cement beams that have been built. The ring base plate 8 is welded on the center of the circle support ring 9 and four crossbeams 6. The top of the ring base plate 8 is a circle support ring 10, and the upper end arc of the circle support ring 10 matches the bottom arc of the chemical reactor 5 cylinders. The lower ends of the four braces 7 are welded to the crossbeam 6 and the circular bottom plate 8, and the arc surfaces of the upper ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com