Roof frame installation structure and car comprising same

A technology for installing structures and roofs, which is applied to the upper structure, upper structure sub-assembly, vehicle parts, etc., can solve the problems of large deformation of the upper part of the car body, threat to the life safety of the occupants, deformation of the roof frame, etc. Effects of vibration, ride comfort improvement, and strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

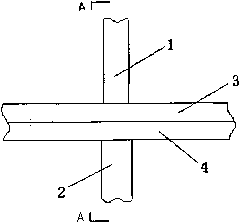

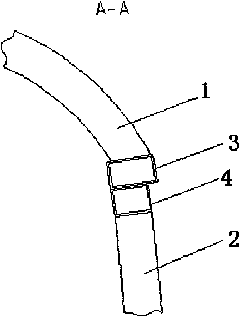

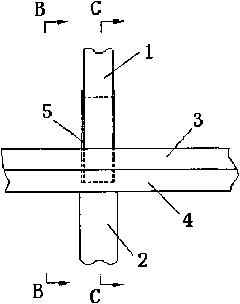

[0031] The car roof frame is generally a frame structure composed of rectangular pipe beams. The beams on both sides of the roof frame are called roof side beams 3, and the roof side beams 3 are respectively fixed to the left and right sides by welding. The side wall of the framework is on the upper stringer 4. A plurality of roof beams 1 parallel to each other are fixed between the roof side beams 3 on both sides of the roof frame along the longitudinal direction of the vehicle. Typically, each roof beam 1 is located at 2 side columns corresponding to the side frame. In the same cross-section of the car (the lower section of the side wall column 2 is fixed to the corresponding beam of the car floor frame), thereby forming a plurality of closed stress rings in multiple cross-sections of the car perpendicular to the longitudinal direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com