Preparation method of thermochromism sensing materials

A sensing material and thermochromic technology, applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of complicated operation, unfavorable detection, inconvenient carrying, etc., and achieve the effect of simple preparation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of thermally induced reversible discoloration solid-state sensing material of polydimethylsiloxane / glutamic acid-based polydiacetylene

[0038] (1) Synthesis of glutamate-based diacetylene molecules

[0039] References (Cheng Quan et al., Langmuir, 2000, volume 16, page 5334, Langmuir, 1998, volume 14, page 1974) in the synthetic glutamate-based diacetylene molecule, the specific method comprises the following steps:

[0040] 1) 0.34g 10,12-pentacethynoic acid [CH 3 -(CH 2 )11 -C≡C-C≡C-(CH 2 ) 8 -COOH] was dissolved in 20mL of dichloromethane, then added successively 0.14g N-hydroxysuccinimide, 0.23g1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, in The reaction was stirred (300 rpm) at room temperature for 12 hours. Concentrate the mixed solution on a rotary evaporator, then add 20 mL of ethyl acetate, and extract with water. The obtained organic phase was washed with anhydrous Na 2 SO 4 Dry for 12 hours and evaporate to dryness with a ...

Embodiment 2

[0050] Preparation of polydimethylsiloxane / pentacenoic acid polydiacetylene thermochromic solid-state sensing material

[0051] 1) Dissolve pentasynoic acid diacetylene in chloroform to obtain a 1mM solution; take 2.14mL of the above solution and mix it with 1.5g polydimethylsiloxane and 0.1g curing agent to obtain a mixture solution, and then remove the mixture under reduced pressure After adding chloroform in the solution, the mixture was cured at 30°C for 24 hours, and the cured product was irradiated for 5 seconds under a 254nm ultraviolet lamp to polymerize the polydiacetylene of pentadecynoic acid to form polydiacetylene and obtain a blue color. Thermochromic solid-state sensing materials;

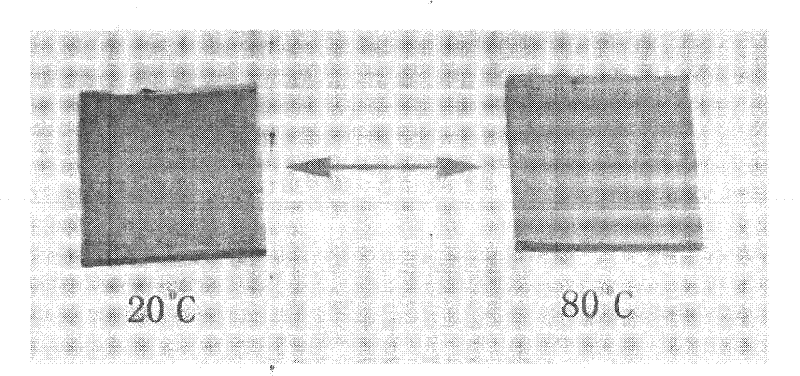

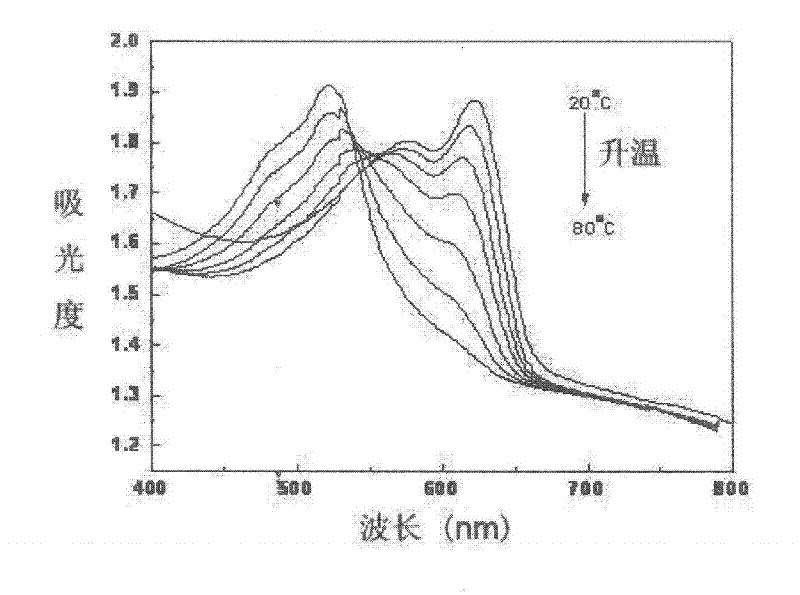

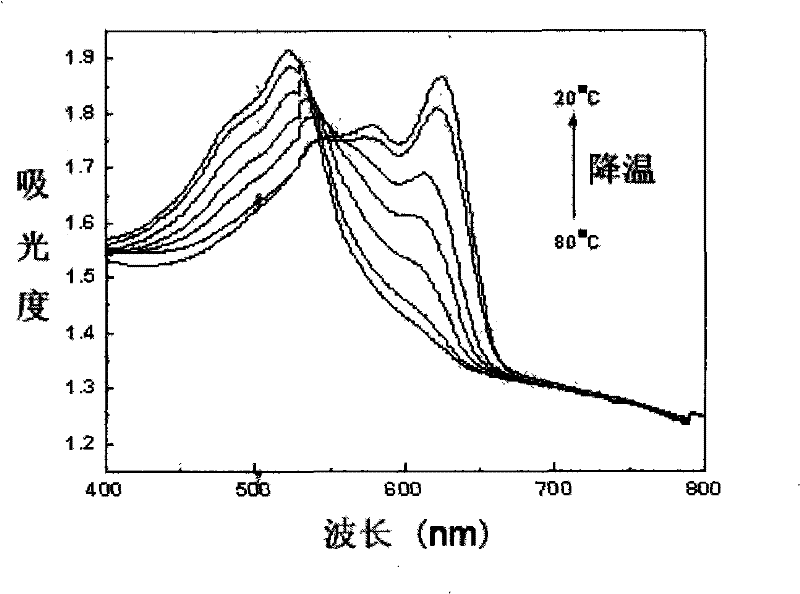

[0052] 2) The thermochromic solid-state sensing material obtained in step 1) is heated from 20°C to 80°C, and then cooled from 80°C to 20°C. The color of the thermochromic solid-state sensing material gradually changes from blue to purple and then red during the heating process, and...

Embodiment 3

[0054] Preparation of polydimethylsiloxane / glutamic acid-based polydiacetylene thermally induced reversible discoloration liquid sensing material

[0055] (1) Synthesis of aminodiacetylene molecule

[0056] The synthetic aminodiacetylene molecule in bibliography (Richard E.Bruehl etc., Biochemistry, 2001, the 40th volume, 5964 pages), concrete method comprises the following steps:

[0057] 1) Mix 10mL 2.4mmol / L C 6 h 11 N=C=NC 6 h 11 The dichloromethane solution was added to 10mL2.45mmol / L 10,12-pentacosyldiynoic acid [CH 3 -(CH 2 ) 11 -C≡C-C≡C-(CH 2 ) 8 -COOH] in the dichloromethane solution, stirred (300 rpm) at room temperature and reacted for 1 hour to obtain a mixed solution;

[0058] 2) Add the mixed solution obtained in step 1) dropwise to 10 mL of 4 mmol / L ethylenediamine in dichloromethane solution within 20 minutes, and continue stirring (300 rpm) for 1 hour of reaction;

[0059] 3) The reaction solution obtained in step 2) was diluted with 20mL petroleum e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com