Revolving furnace slag pressing agent and revolving furnace slag pressing method

A technology of slag pressing agent and converter, which is applied in the field of converter slag pressing agent and converter slag pressing method, can solve problems such as slag foaming, slag gushing at the furnace mouth, and the lack of conditions for direct furnace tapping, etc., and achieves improvement effects and broad Application prospect, effect of reducing slag overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation of the present invention will be further described below in conjunction with the examples, and the present invention is not limited to the scope of the examples.

[0011] Embodiment Using converter slag pressing agent of the present invention to carry out slag pressing treatment

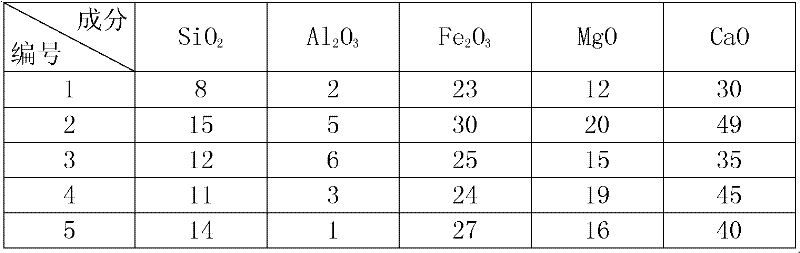

[0012] 12 stoves of converters were added respectively to the converter slag pressing agent of the present invention to carry out the slag pressing treatment (the chemical composition of the converter slagging agent of the present invention is as shown in Table 1), and the converters (converter 13th, 14, 15 heats) for comparison, the results are shown in Table 2.

[0013] Table 1 Chemical composition (parts by weight) of converter slag pressing agent of the present invention

[0014]

[0015] Table 2 Results of slag pressing test

[0016]

[0017] Note: The capacity of the above-mentioned converters is 120 tons.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com