Constant speed device for tandem vibratory roller

A technology of vibratory road roller and constant speed device, which is applied in the field of construction machinery, can solve the problem of operator fatigue and boredom, and it is difficult to move forward or backward. requirements and other issues, to achieve the effect of simple operation, practical operation and meeting speed requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

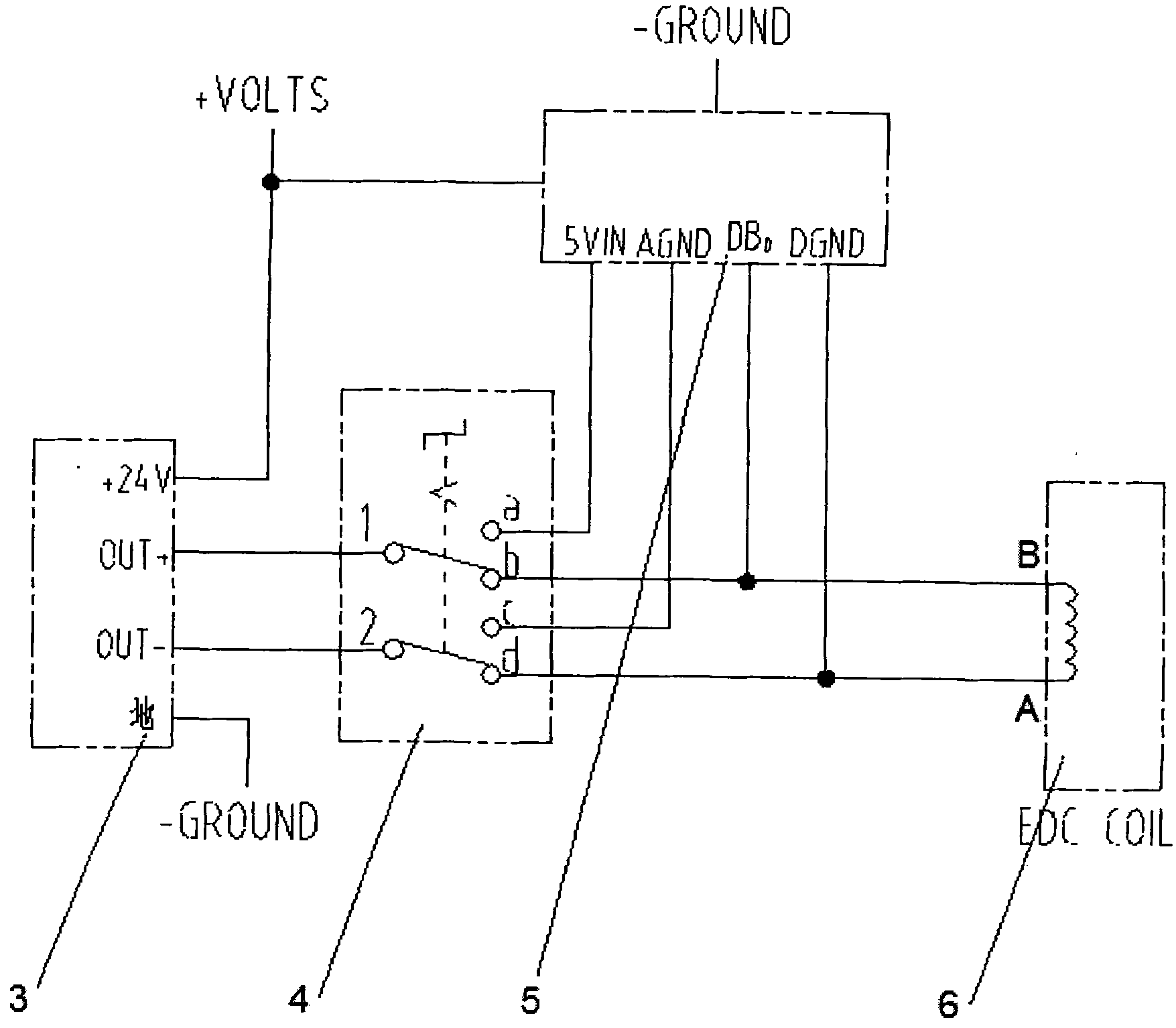

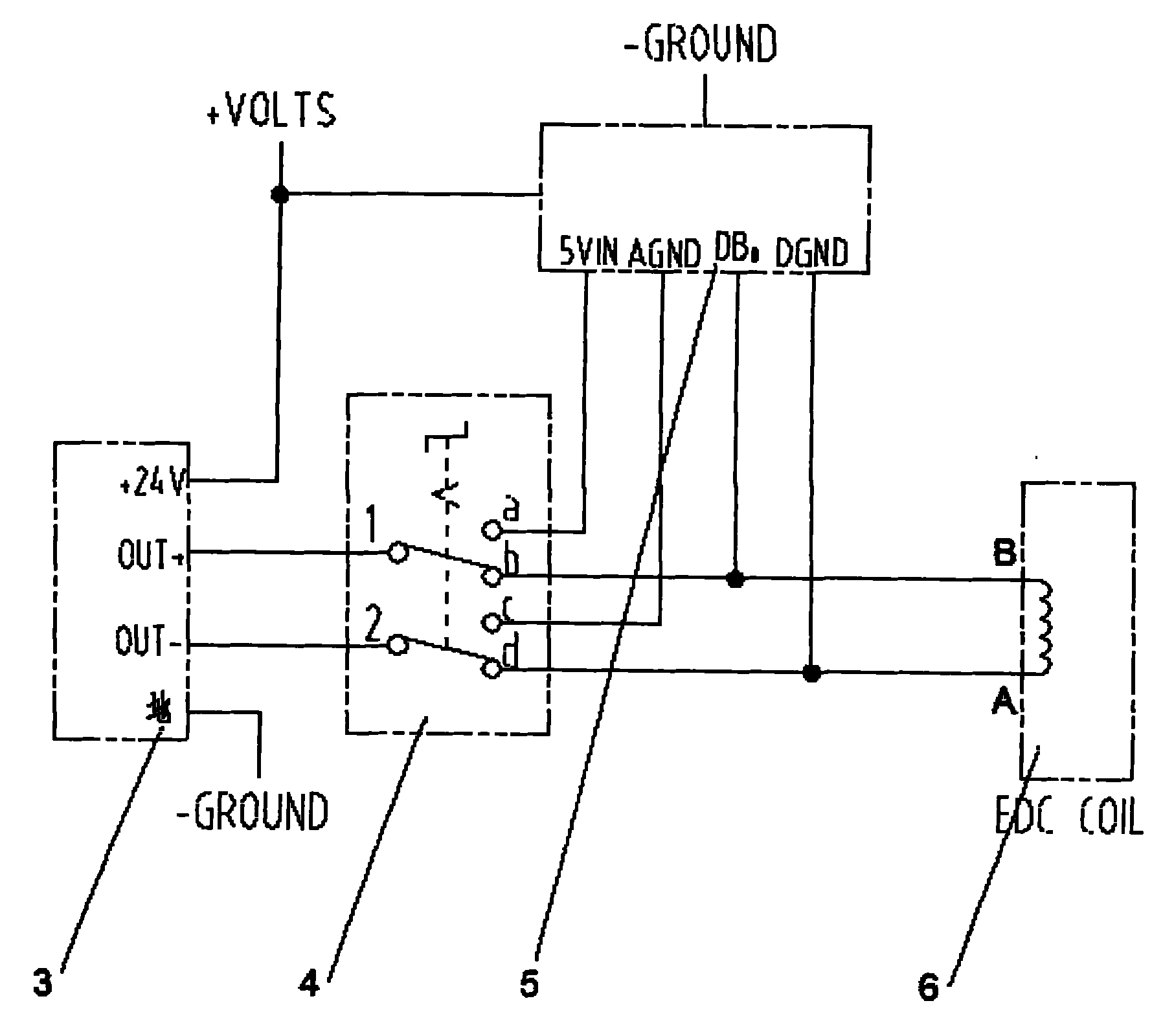

[0011] see figure 1 , figure 1 It is the principle block diagram of the constant speed device of the double steel wheel vibratory road roller of the present invention. Depend on figure 1 It can be seen that the speed-fixing device of the double-steel-wheel vibratory roller of the present invention includes a variable-speed control handle 3 and an A / D conversion circuit 5, and is characterized in that it adds a constant-speed mode on the control panel of the double-drum vibratory roller. Switch 4, the constant speed mode switch 4 has two normally closed contacts 1-b, 2-d and two normally open contacts 1-a, 2-c, the two inputs of the constant speed mode switch 4 Terminals 1 and 2 are connected to the OUT+ and OUT- terminals of the shift control handle 3 respectively. At the output end of the constant speed mode changeover switch 4, the two normally closed ports b and d of the constant speed mode changeover switch 4 are respectively connected with the two ends of the coils A a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com