All-sealed vibration damping and water preventing device with large regulating quantity

A waterproof device and fully-sealed technology, applied in bridge parts, bridges, buildings, etc., can solve the problems of unsatisfactory sealing and waterproofing of waterproof devices, seams at the joints of bolts or hoop, functional defects, etc., and achieve the effect of overcoming the bad situation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

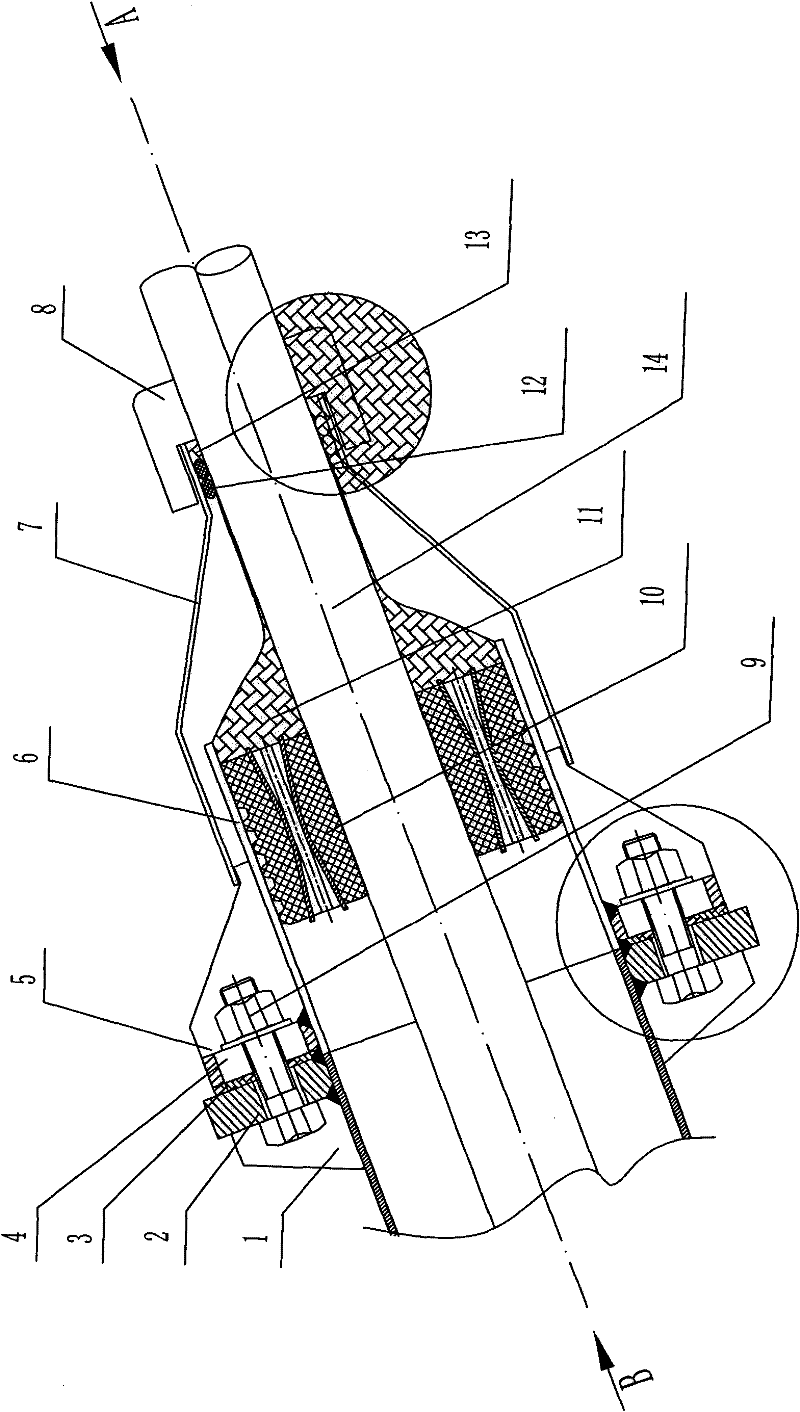

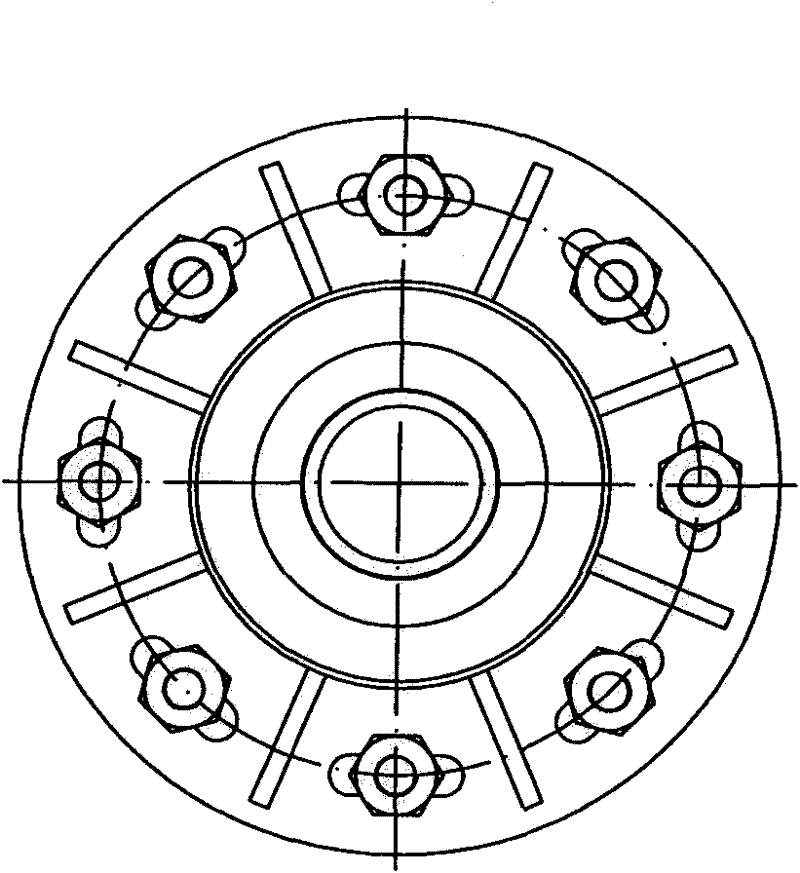

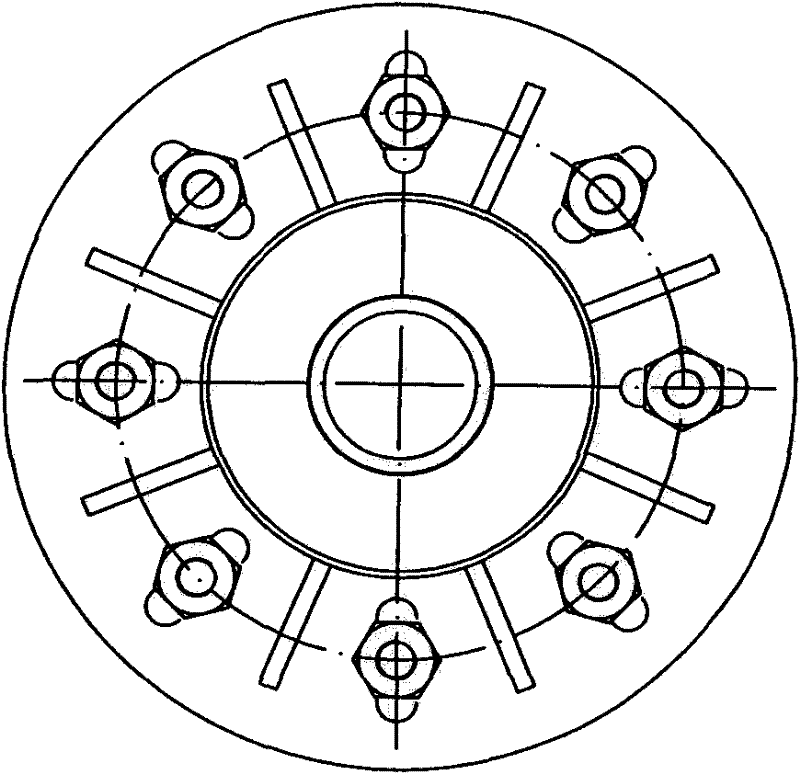

[0015] see Figure 1-3 , figure 1 It is a schematic diagram of the overall structure of the fully-sealed vibration-damping and waterproof device with a large adjustment amount of the present invention. figure 2 for figure 1 A view from direction A. image 3 for figure 1 B direction view. Depend on figure 1 , figure 2 with image 3 It can be seen that the large adjustment amount of the present invention is a fully sealed vibration damping and waterproof device, the device is an upper and lower flange structure, including an upper flange 4, a lower flange 2 and a sleeve 6, the upper flange 4 and the lower flange The flange 2 is set up and down, the upper flange 4 is fixedly set on the lower part of the sleeve 6, the rubber pad 3 is embedded between the upper flange 4 and the lower flange 2, and the upper flange 4 and the lower flange are connected by bolts 9. The flange 2 and the rubber pad 3 are pierced and fixed, and the upper rib plate 5 and the lower rib plate 1 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com