Anti-falling screw component with anti-loose function

A screw assembly and anti-loosening technology, applied in the direction of screws, threaded fasteners, nuts, etc., can solve the problems of non-concentricity of anti-loosening parts and screws, poor anti-loosening effect of screws, etc., to achieve good anti-loosening effect, not easy to lose, Improve the effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

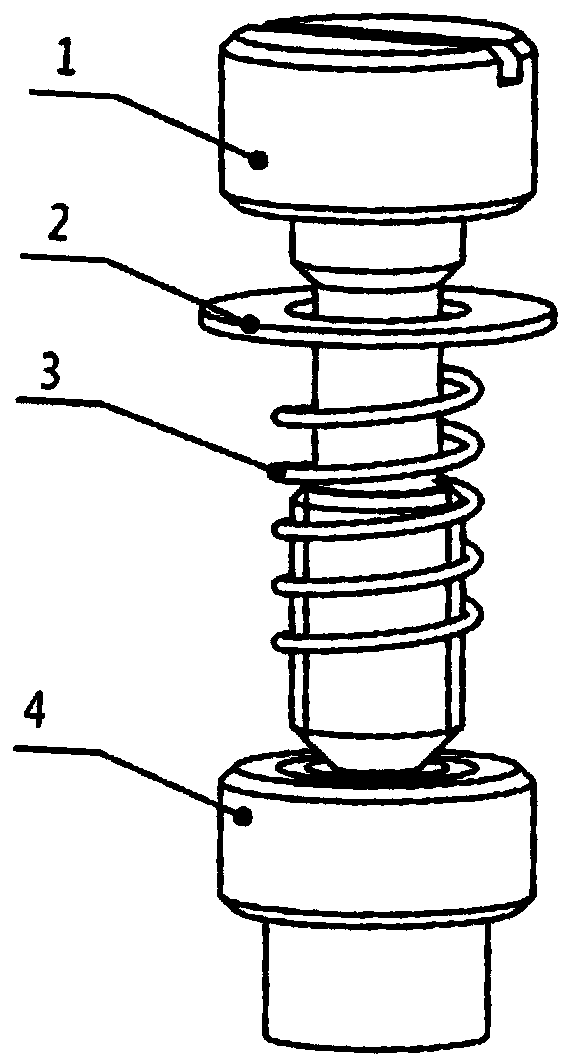

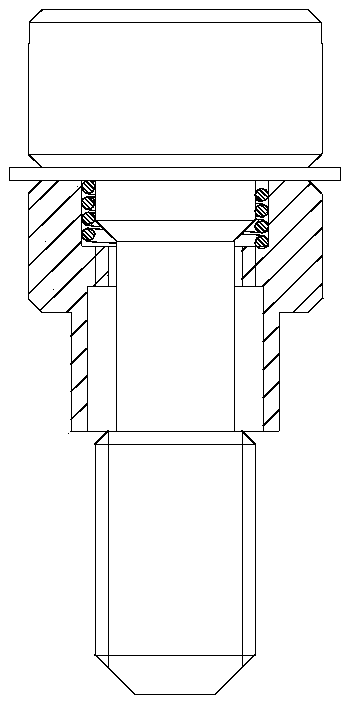

[0032] This embodiment provides a non-falling screw assembly with anti-loosening function, such as Figure 1 to Figure 2 As shown, it includes a screw 1, an anti-loosening part 2 and a fixing sleeve 4; the anti-loosening part 2 is arranged between the screw 1 and the fixing sleeve 4; the anti-loosening part 2 is elastic, and a round hole for the screw 1 to pass through is provided on it The fixed sleeve 4 is a sleeve-shaped structural part with internal threads. After the screw is tightened, the upper surface of the fixed sleeve 4 is in close contact with the lower surface of the anti-loosening part 2; the lower end of the screw head of the screw 1 is provided with an annular step (not shown in the figure) marked), the diameter of the annular step is slightly smaller than the inner diameter of the anti-loosening part 2, and the anti-loosening part 2 remains concentric with the screw head after being compressed.

[0033] During implementation, first connect the fixing sleeve 4 ...

Embodiment 2

[0042]This embodiment provides a method of using a non-loosening screw assembly with an anti-loosening function. When the non-loosening screw assembly needs to be installed on a panel, the fixing sleeve is first connected to the panel, and then the anti-loosening part and the spring are successively connected to each other. Install it on the non-falling screw, and then screw the non-falling screw together with the anti-loosening part and the spring onto the thread of the fixing sleeve to complete the installation of the non-falling screw assembly on the panel. Tighten the non-falling screw during work, the spring is compressed into the counterbore of the fixing sleeve, the anti-loosening part is pressed between the head of the non-falling off screw and the upper end surface of the fixing sleeve, and the anti-loosening part is concentric with the head of the non-falling off screw.

[0043] The chassis panels and cabinets or racks installed by this method are firm and durable, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com