Plate type switch bed plate bolt hole construction site drilling method

A technology of construction site and drilling method, which is applied in the field of drilling method manufacturing field of bolt hole construction site of slab turnout backing plate, can solve the problems of many bolt holes, low processing efficiency, and centering, so as to ensure centering accuracy and coaxiality degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

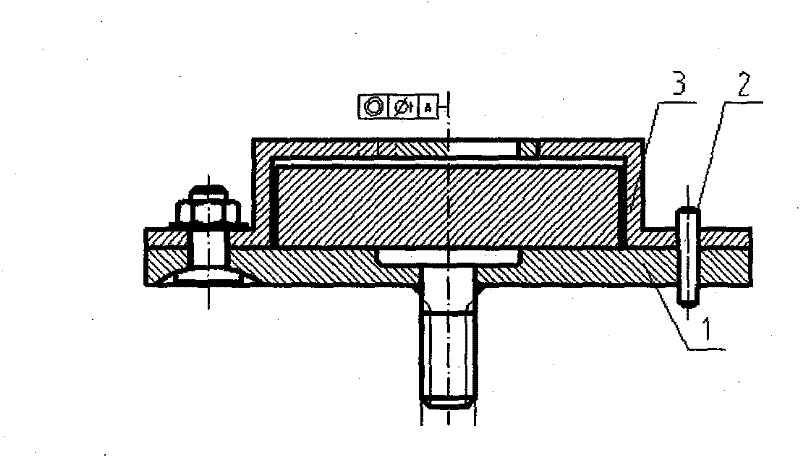

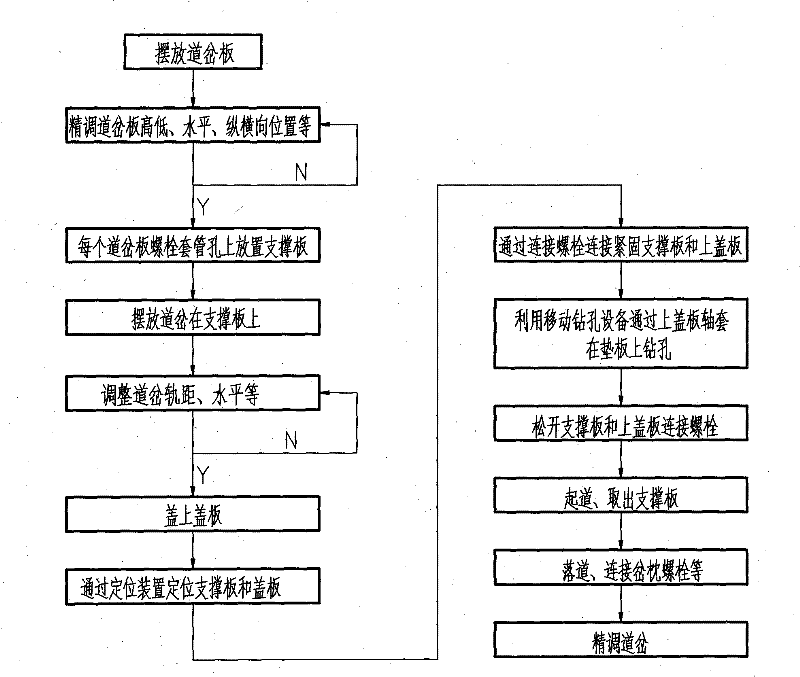

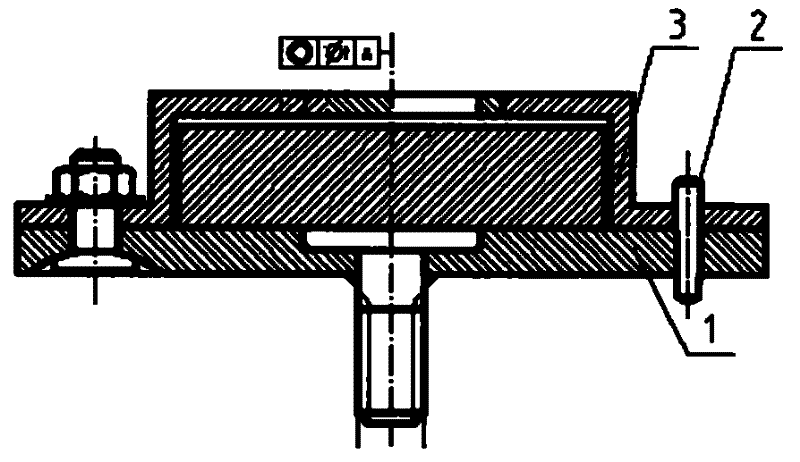

[0013] Embodiment 1: with reference to attached figure 1 and 2 . Tooling consists of 2 parts:

[0014] 1) Support plate: The support plate is composed of a support plate substrate with connecting bolt holes and positioning pin holes and an M30 screw perpendicular to it by welding. At the same time, the through groove is milled out in the middle part of the base body of the support plate, so as not to damage the support plate after the drill drills through the backing plate. The support plate is used to support the turnout after the turnout is fine-tuned, and the M30 screw on the support plate is connected to the turnout bolt sleeve on the turnout plate to locate the position of the support plate.

[0015] 2) Cover plate: The cover plate is composed of drill sleeve, pin hole and bolt connection hole. The position between it and the support plate is positioned by the conical pin, and the position between the cover plate and the support plate is fixed by bolt connection.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com