Connection structure of over-long roof of greenhouse

A connection structure and super-long technology, applied in the field of aluminum alloy profiles, can solve the problems of difficult design and installation of roof aluminum alloy profiles, difficulty in achieving design and installation effects, and achieve the effect of strengthening support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

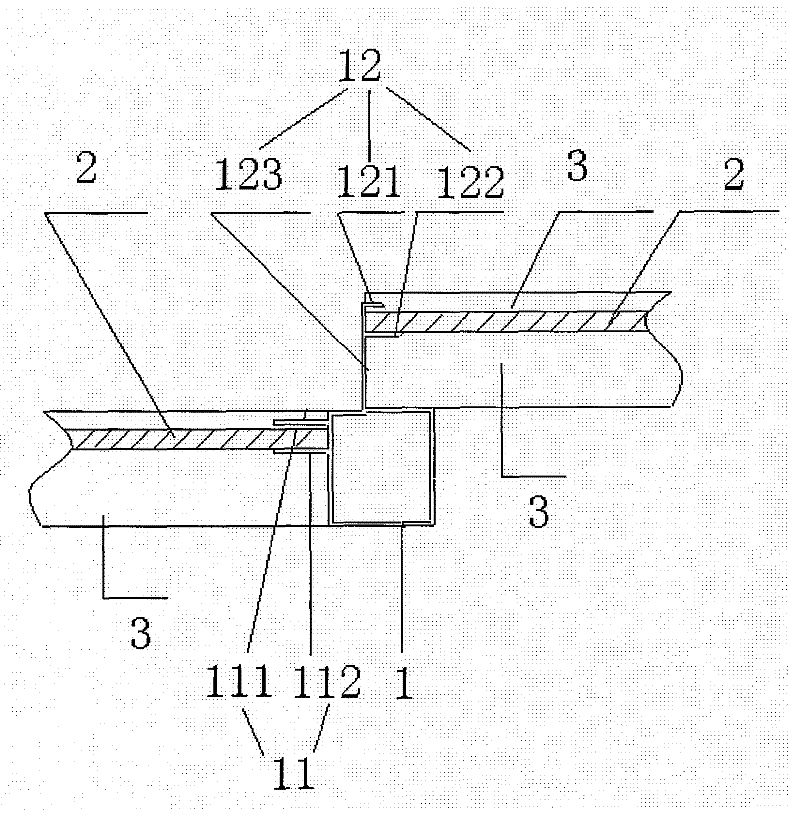

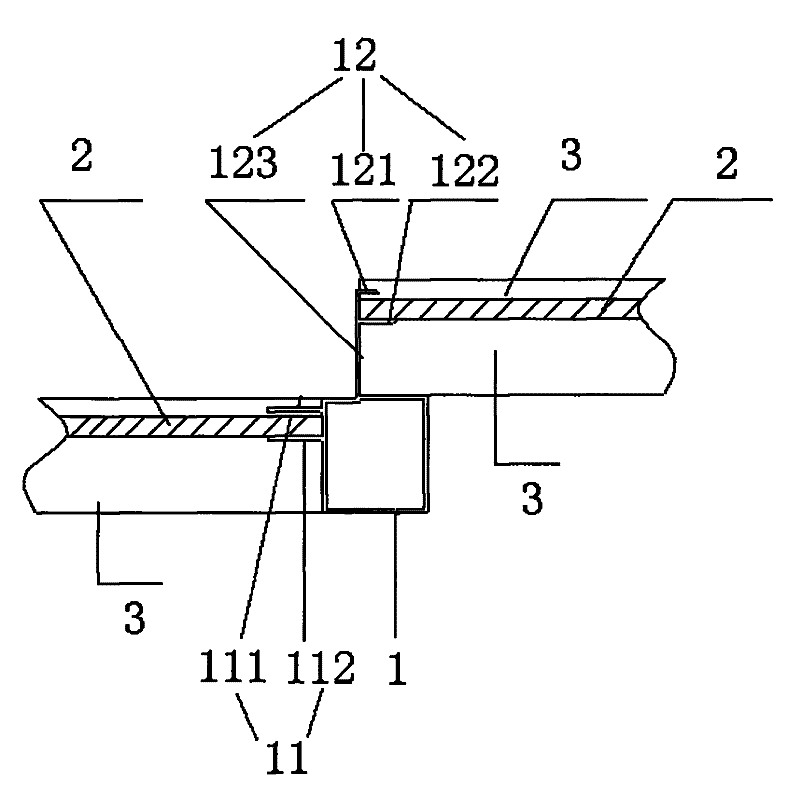

[0027] The connection structure of the super long roof of the greenhouse, such as figure 1 As shown, it includes connector 1, profile 1 (11) and profile 2 (12), glass 2 and roof strip 3.

[0028] Glass 2 is provided with roof strip 3 near the edge position.

[0029] The connecting piece 1, the profile 1 (11) and the profile 2 (12) are integrally structured.

[0030] The connecting piece 1 adopts a cuboid structure made of aluminum alloy, and the cuboid body is set as a hollow structure in order to reduce weight and save cost.

[0031] One side of the connector 1 is provided with a profile 1 (11) for accommodating the edge of the glass 2, and the other side of the connector 1 is provided with a profile 2 (12) for accommodating the edge of the glass 2, and the profile 2 (12) is arranged parallel to the profile 1 (11) .

[0032] Profile 2 (12) is made of aluminum alloy with "F" structure, including support bar 123, upper rail I121 and upper rail II122, supporting bar 123 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com