A construction method of LED filament lamp and LED filament lamp

An LED filament lamp and LED filament technology are applied in the direction of electric lamp circuit layout, components of lighting devices, semiconductor devices of light-emitting elements, etc., which can solve the problems of reducing the versatility and interchangeability of LED filaments, the large size of driving power supply, and the layout of power supply. Difficulties and other problems to achieve the effect of reducing the difficulty of assembly, improving conversion efficiency and power factor, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

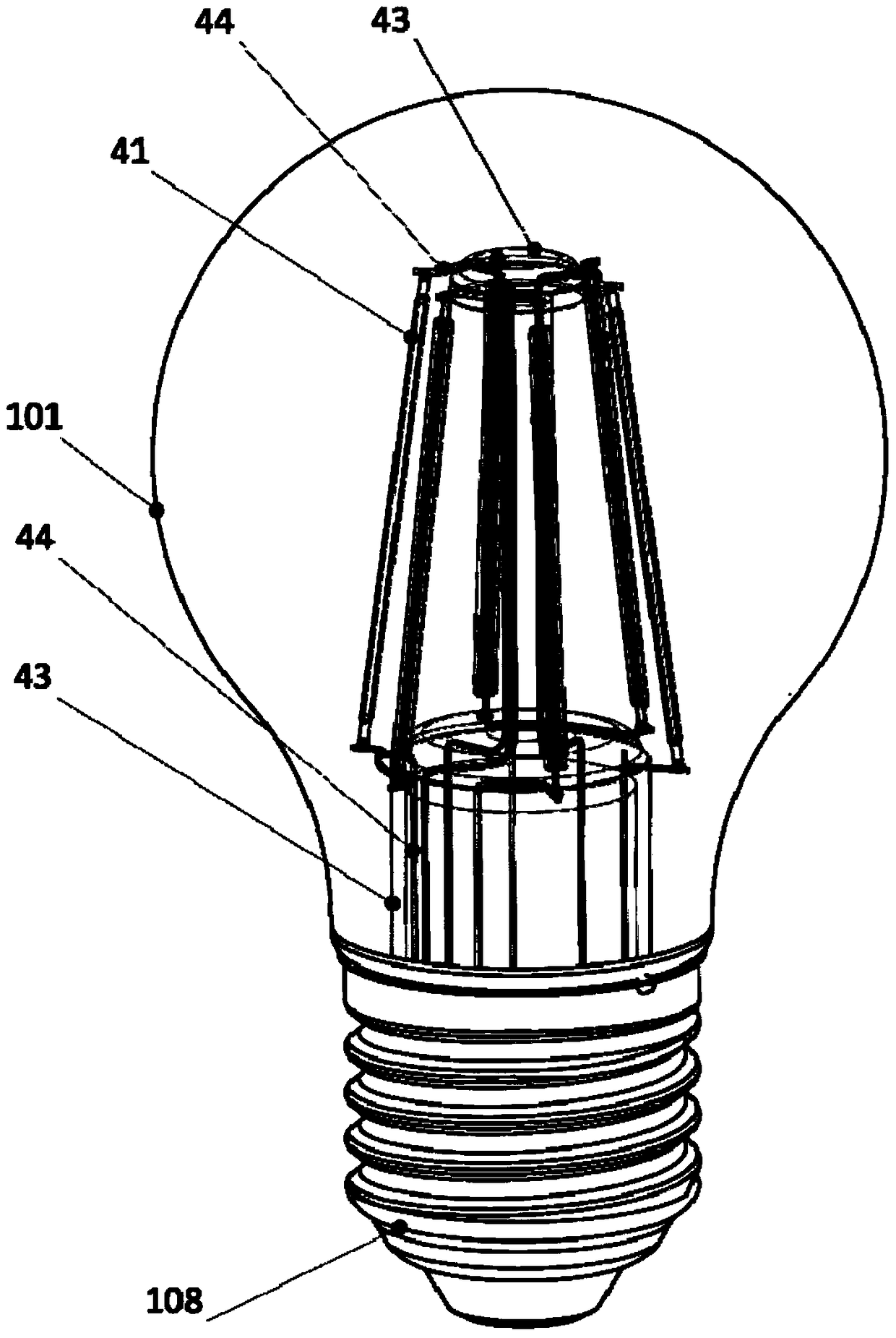

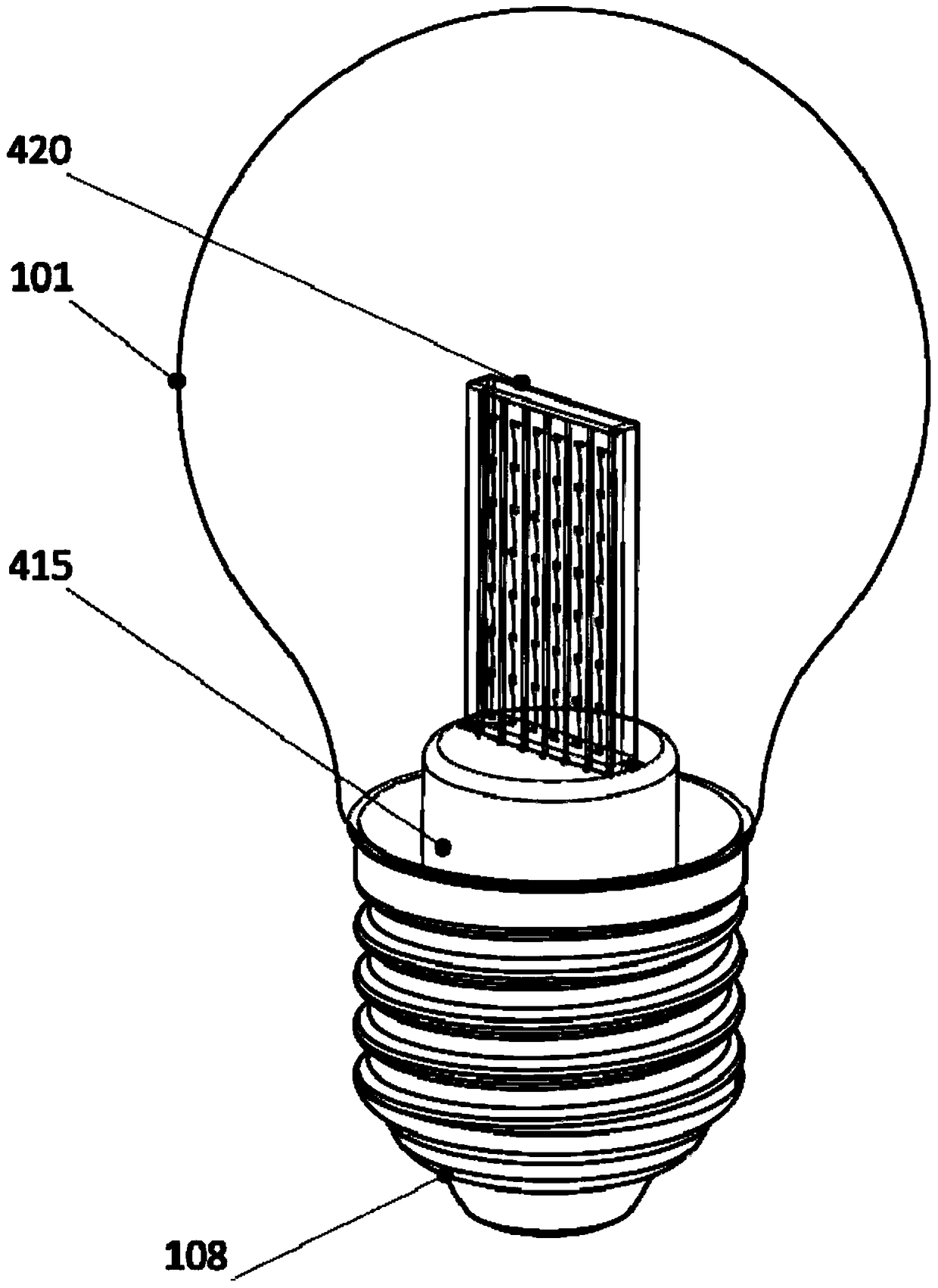

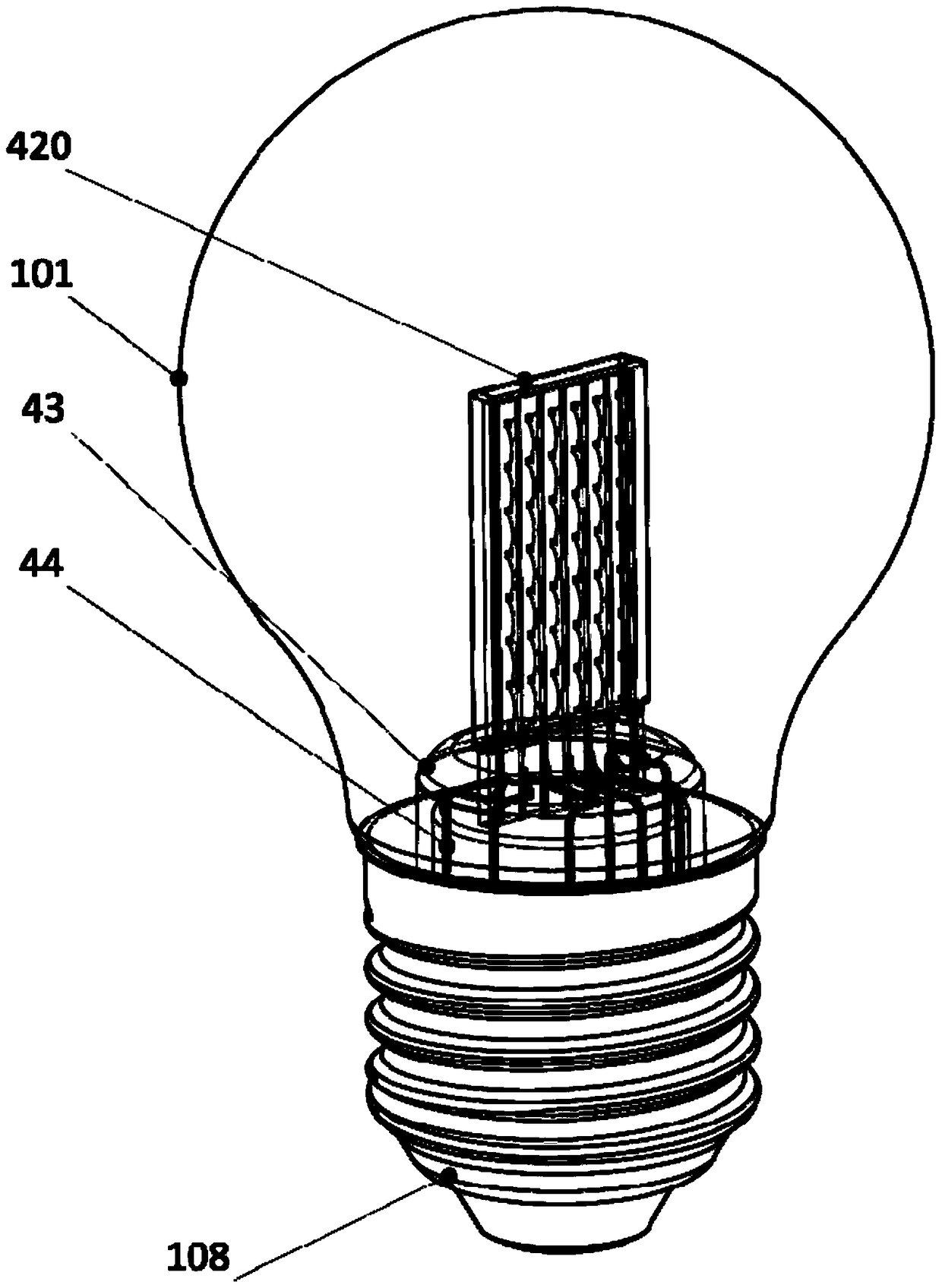

[0044] Example. A method for constructing an LED filament lamp: a bulb shell and a lamp cap are arranged outside the LED light source core component, and wires are arranged to connect the LED light source core component with the lamp cap to form an LED filament lamp; the LED light source core component consists of an LED filament group, a built-in LED drive power supply module and binding posts; the LED filament group is composed of multiple LED series groups connected in series; the LED series group is packaged in series on a strip-shaped substrate by multiple LED chips or LED PN junctions to form an LED The filament, or the plurality of LED series groups are all packaged in series on the same substrate to form a combined LED filament; the two ends of the LED filament group are connected to the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com