Special gearbox for agricultural forklift

A gearbox and gearbox body technology, applied to components with teeth, lifting devices, gear transmissions, etc., can solve problems affecting market competitiveness, unreasonable working speed, and large space occupation, and achieve compact structure, Reduced footprint and large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

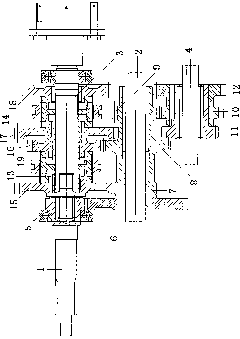

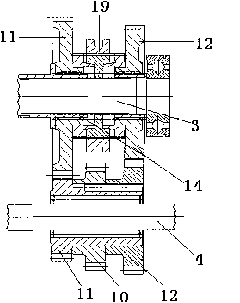

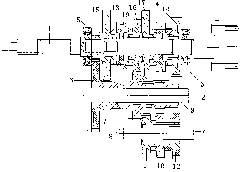

[0013] A special gearbox for agricultural forklifts, including a gearbox body, in which an input shaft 1, an intermediate shaft 2, an output shaft 3, and a reverse gear shaft 4 are rotatably installed in the gearbox body, and a driving gear 5 is fixedly mounted on the input shaft 1 The intermediate shaft 2 is fixedly fitted with a constant meshing gear 6 meshing with the driving gear 5, and the intermediate shaft 2 on the right side of the constant meshing gear 6 is sequentially fitted with a forward first gear driving wheel 7, a forward second gear driving wheel 8 and a driving gear. Idler 9; the reverse gear shaft 4 is fixedly fitted with a passive idler 10 meshing with the active idler 9, and the two sides of the passive idler 10 are respectively fixed with a reverse first gear drive gear 11 and a reverse second gear drive gear 12 Set on the reverse gear shaft 4; the output shaft 3 is fixed with a forward gear synchronizer assembly 13 and a reverse gear synchronizer assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com