Double side acting sealing ring for valve device

A sealing ring and gate technology, applied in valve devices, sliding valves, engine components, etc., can solve problems such as unfavorable installation process, complex structure, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

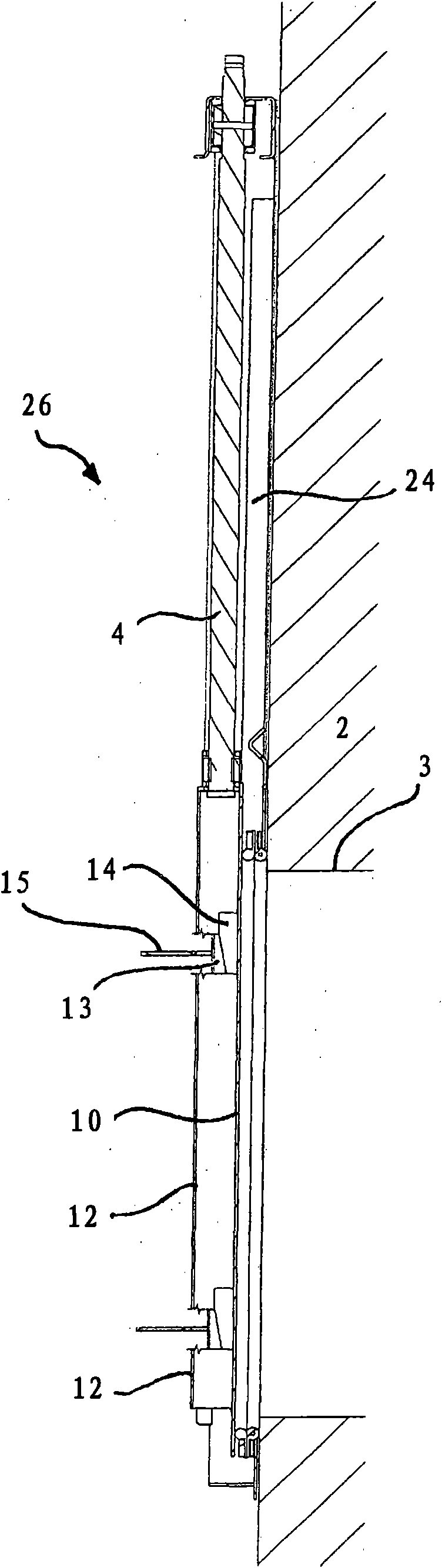

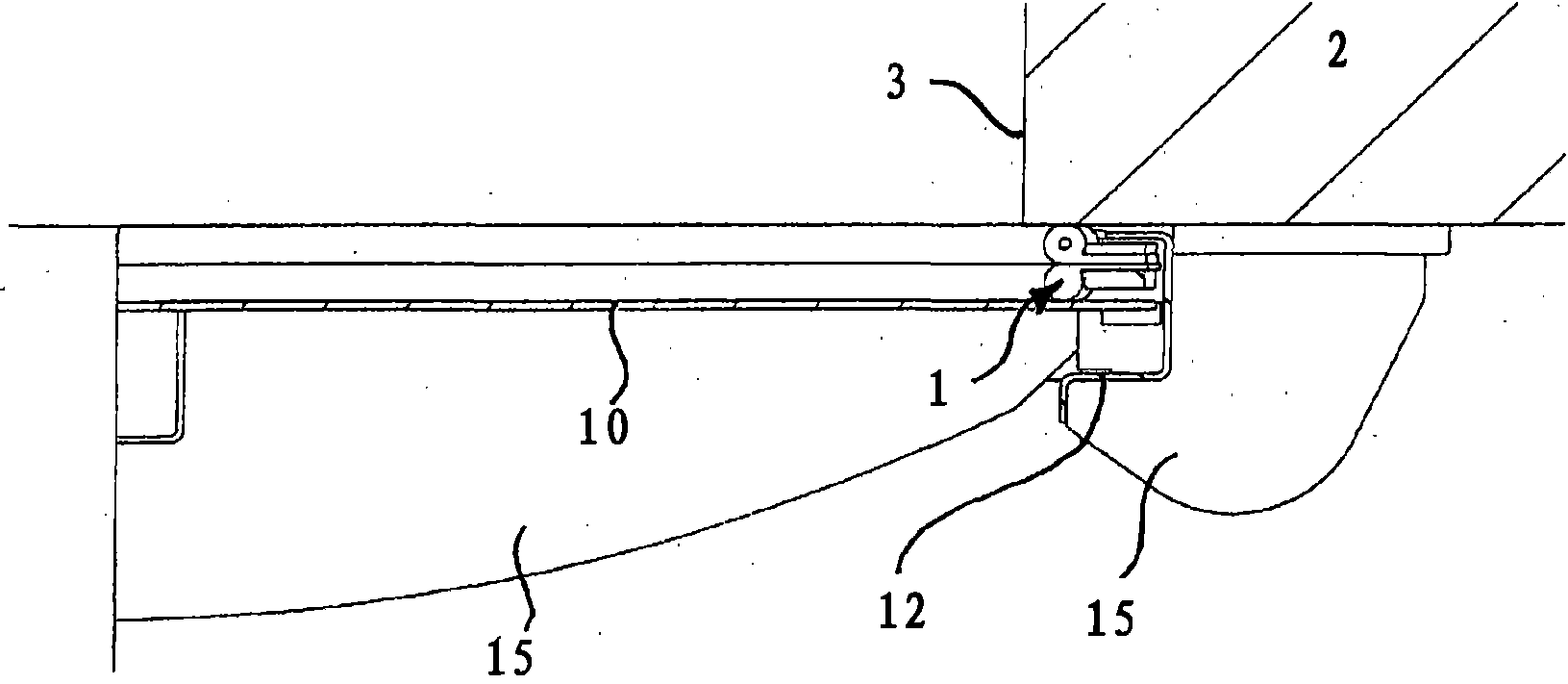

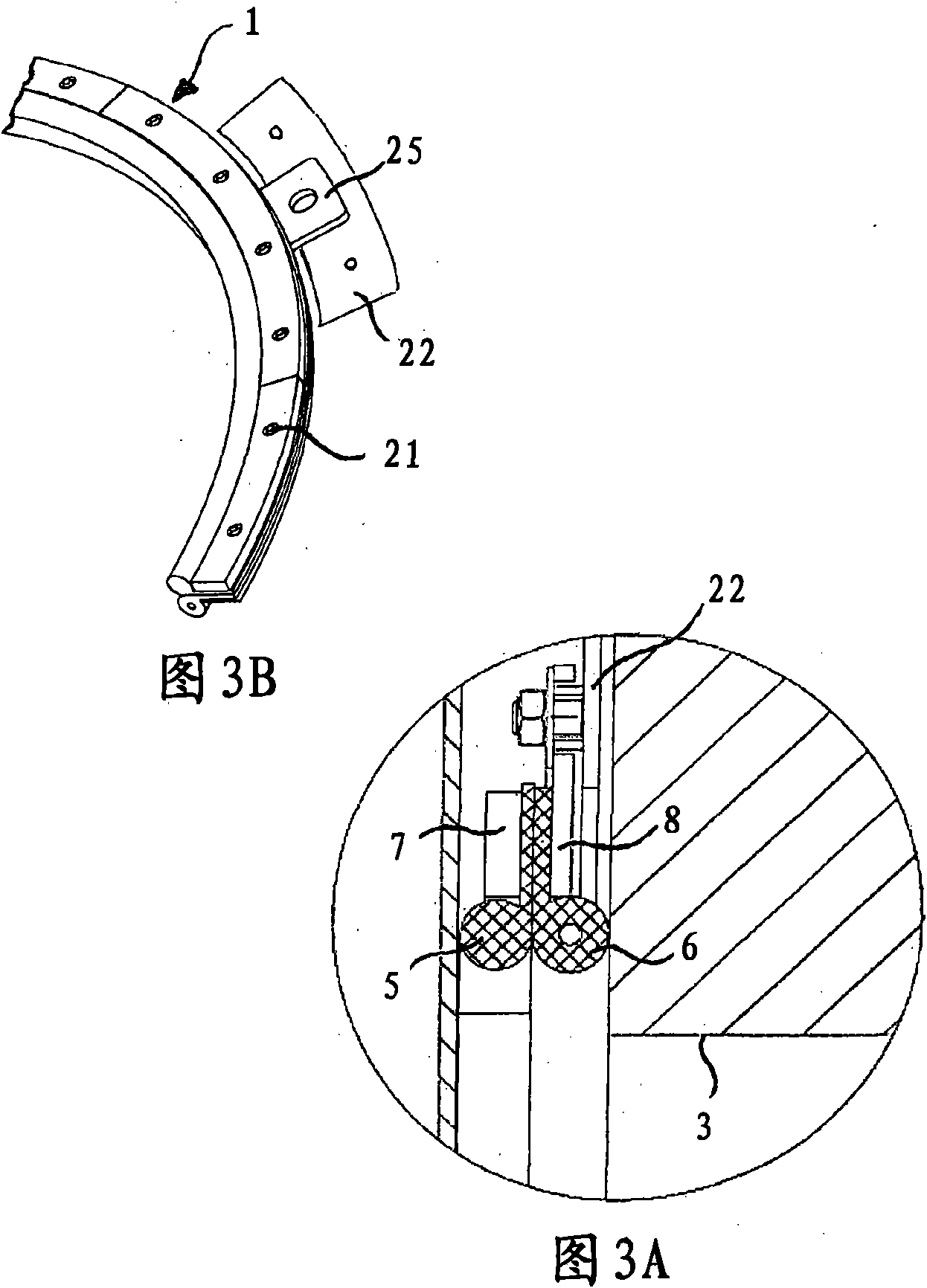

[0027] figure 1 The reference numeral 2 in the figure designates a wall in which an outlet 3 of a channel not shown in detail is arranged. A shutter device 26 is provided for selectively closing the outlet 3 . The gate device 26 is fixed on the wall body 2 through a frame not specified in detail, and includes a shaft (valve rod) 4 and a gate 10 that can move vertically with the shaft 4, and the gate is used to close the gate as required. Outlet 3 of wall 2.

[0028] The shutter device 26 comprises a frame strut 12 on both sides of the shutter 10 in which the shutter 10 is guided vertically. Only in the region of the wedge-shaped structures 13, 14 to be explained below, in figure 1 The frame struts 12 are shown interrupted for better understanding.

[0029] In order to ensure the seal between the shutter 10 and the wall 2 , the shutter device 26 includes a sealing ring 1 which is mounted on the wall side in the region of the outlet 3 , as will be explained in more detail be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com