Integrated composite gasification furnace

A gasifier and integrated technology, applied in the field of biomass gasification furnaces, can solve the problems of inconvenient operation and increased cost, and achieve the effects of fast gas production, less fuel consumption and short distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

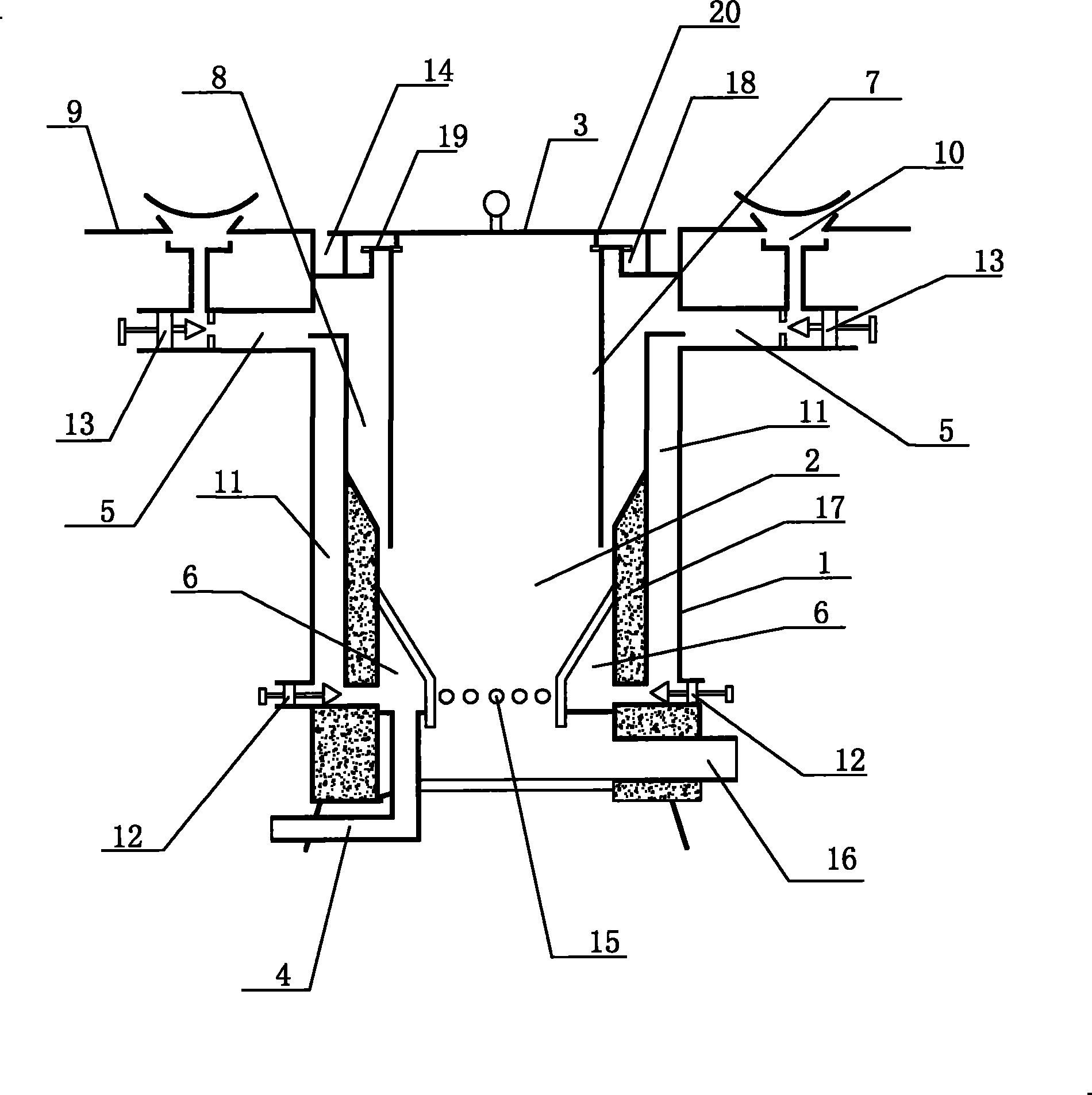

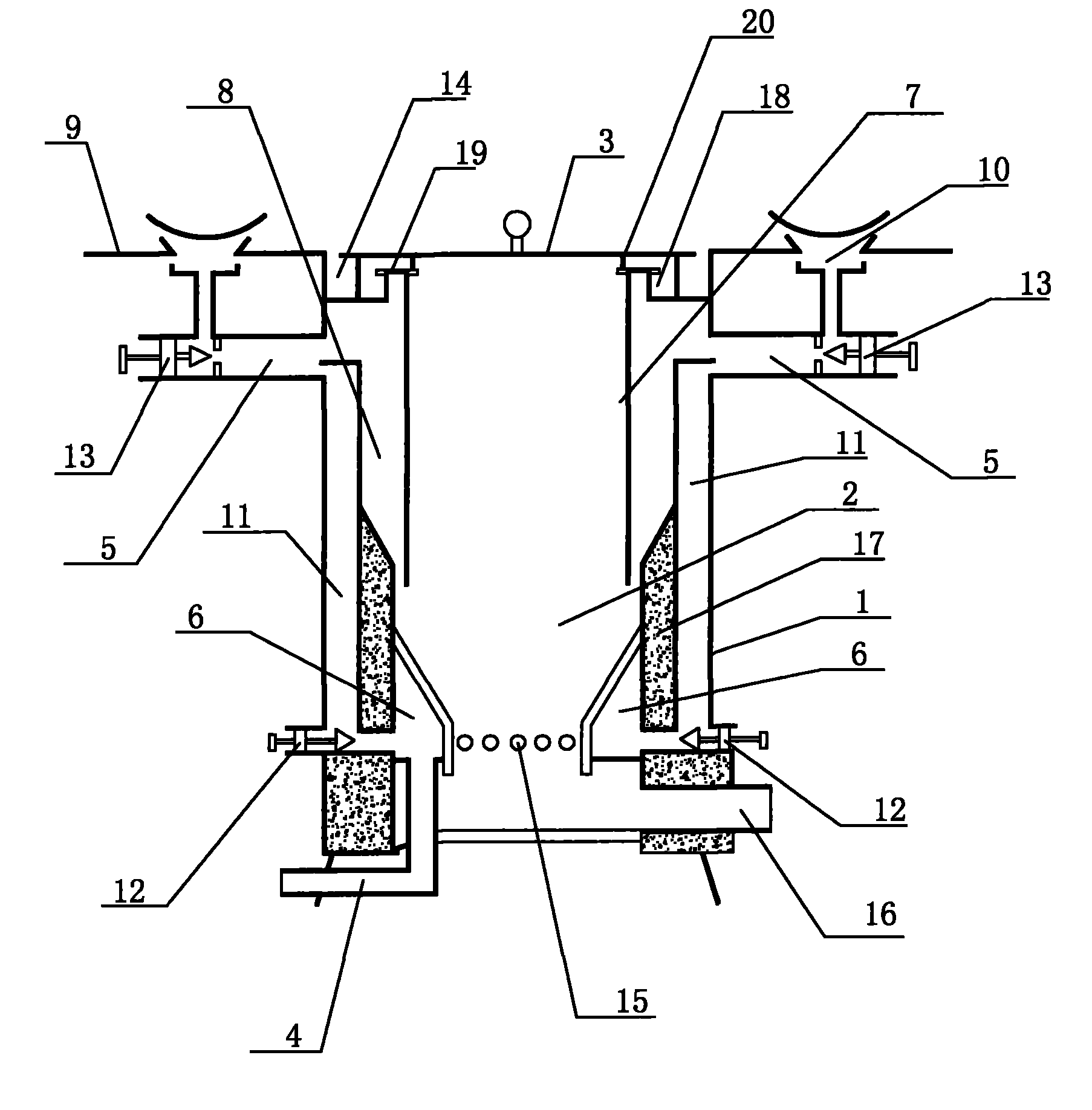

[0013] As shown in the attached figure, in the integrated compound gasification furnace, the middle and lower part of the hearth 2 in the furnace body 1 is provided with an insulating layer 17, and the lower part of the hearth 2 is in the shape of a circular table, and the outer wall of the circular table-shaped part of the furnace body 1 and the inner wall of the furnace body 1 An oxygen supply loop 6 is formed between them, and the oxygen supply loop 6 communicates with the air inlet pipe 4 protruding out of the furnace body. Oxygen supply holes 15 are uniformly arranged on the lower part of the conical part of the furnace 1 , and the oxygen supply holes 15 make the oxygen supply ring 6 communicate with the interior of the furnace 2 . The top of the furnace body 1 is provided with a sealed water tank 14, the top of the storage tank 7 has a snap ring 19, the discharge tank 7 is set on the inner ring 18 of the sealed water tank through the snap ring 19, and the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com