Variable frequency control power module of wind power generator

A wind turbine, frequency conversion control technology, applied in the direction of AC motor control, control system, electrical components, etc., can solve the problems of improper electrical structure wiring, sensitive distributed inductance, power module burnout, etc., to achieve simple and reliable electrical connection, current contact The effects of large area and improved system security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

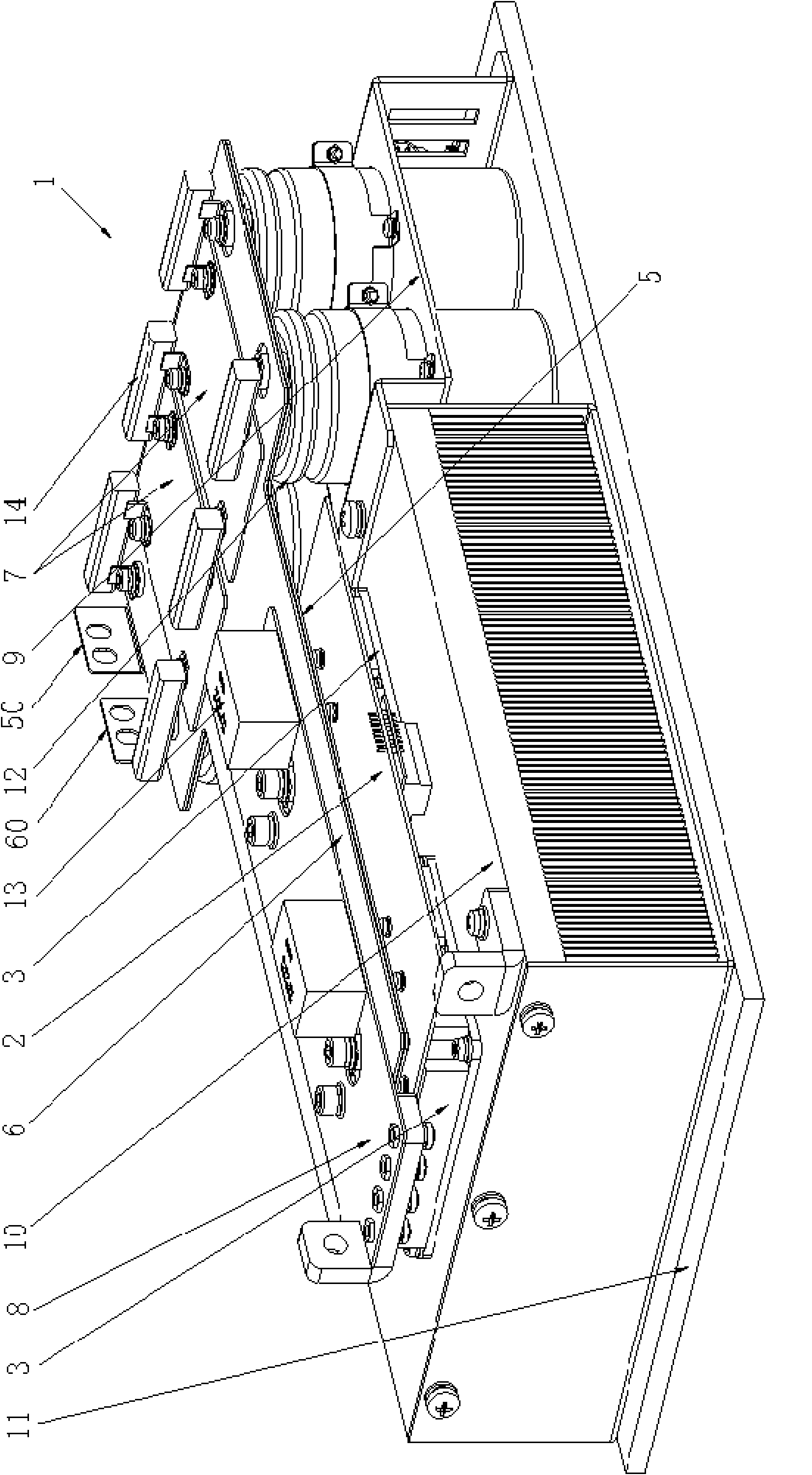

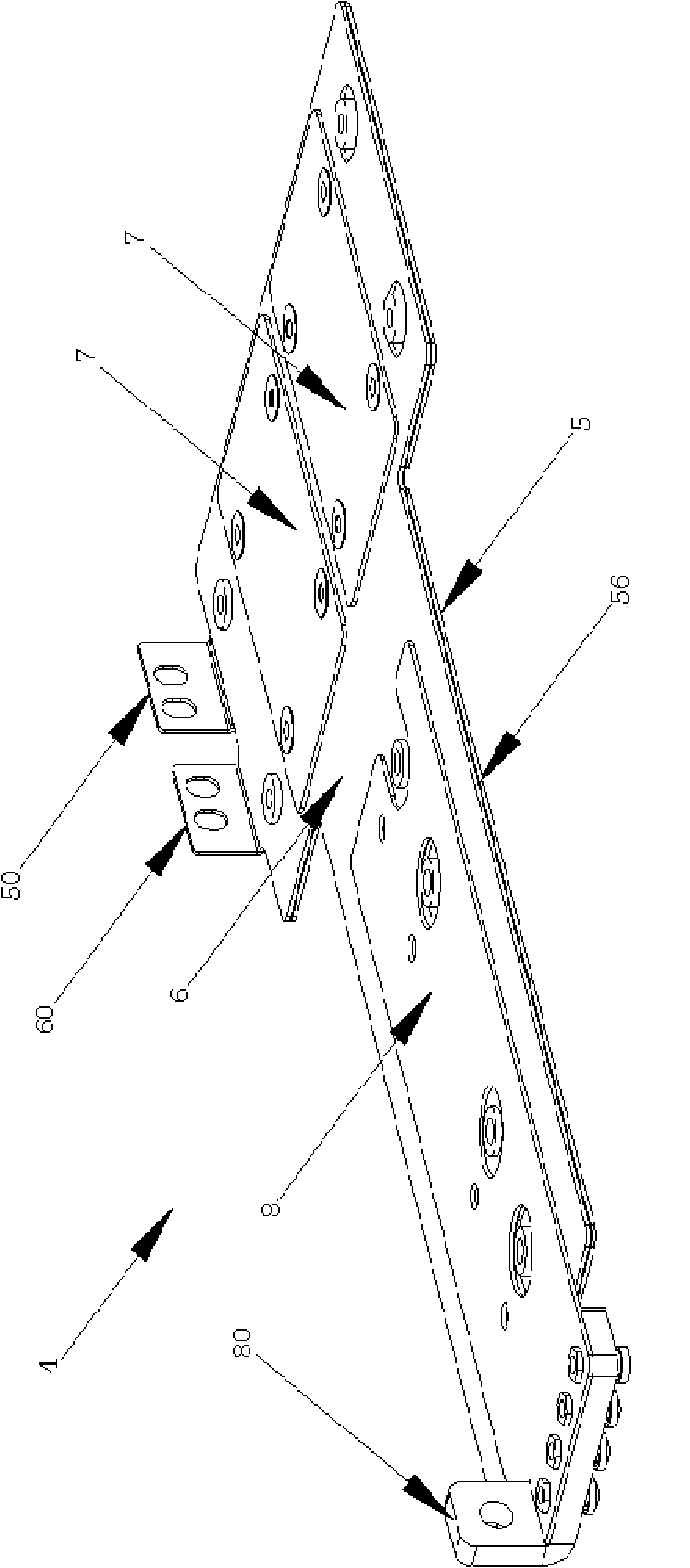

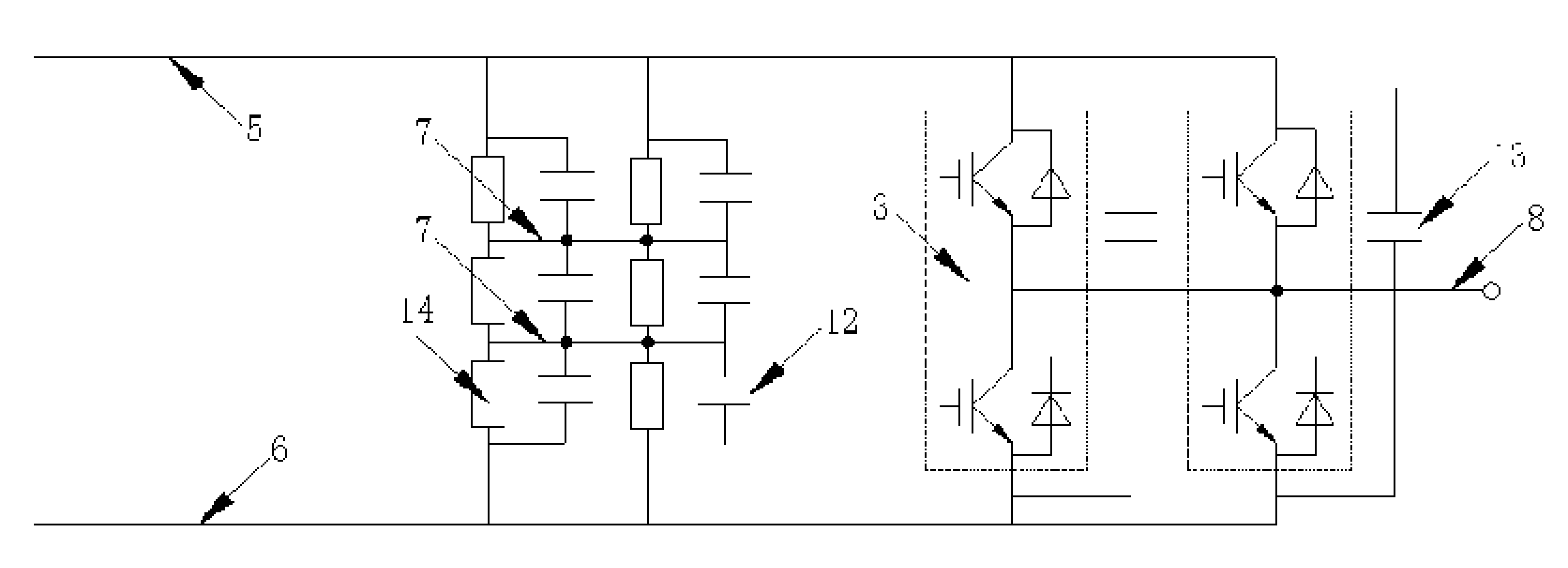

[0026] see figure 1 and figure 2 , the wind power generator frequency conversion control power module of the present invention includes a converter composed of two IGBT modules, a positive DC bus bar 5, a negative DC bus bar 6, an intermediate connecting bus bar 7 and an AC bus bar 8, and the like. The positive DC busbar 5 and the negative DC busbar 6 are respectively composed of two DC conductive plates stacked together. The two DC conductive plates are isolated by an insulating material 56 for the transmission of direct current. The leading ends are respectively marked 50 and 60. The AC busbar 8 is used to transmit AC power, and its leading end is marked as 80 . The 7th row of the middle connection female is used for the electrical connection of the filter circuit. The DC terminals of the two IGBT modules are respectively connected to the positive DC busbar 5 and the negative DC busbar 6, the AC terminal is connected in parallel to the AC busbar 8, and its control termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com