Full-automatic integrated character enclosing machine

A fully automatic and enclosing machine technology, applied to instruments, display devices, markings, etc., can solve the problems of low production efficiency, unsightly appearance, time-consuming and laborious, etc., and achieve the effect of high production efficiency and beautiful font appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

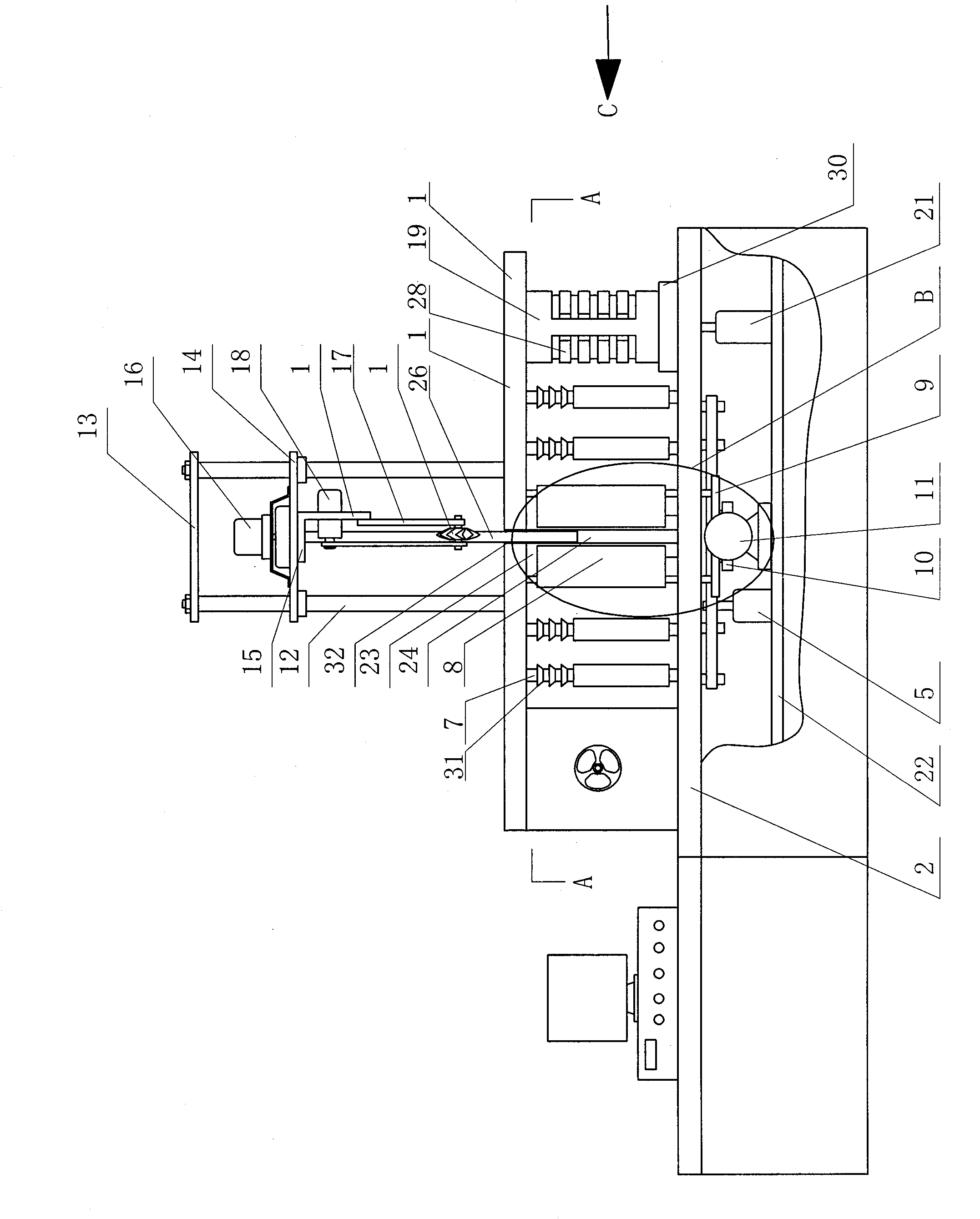

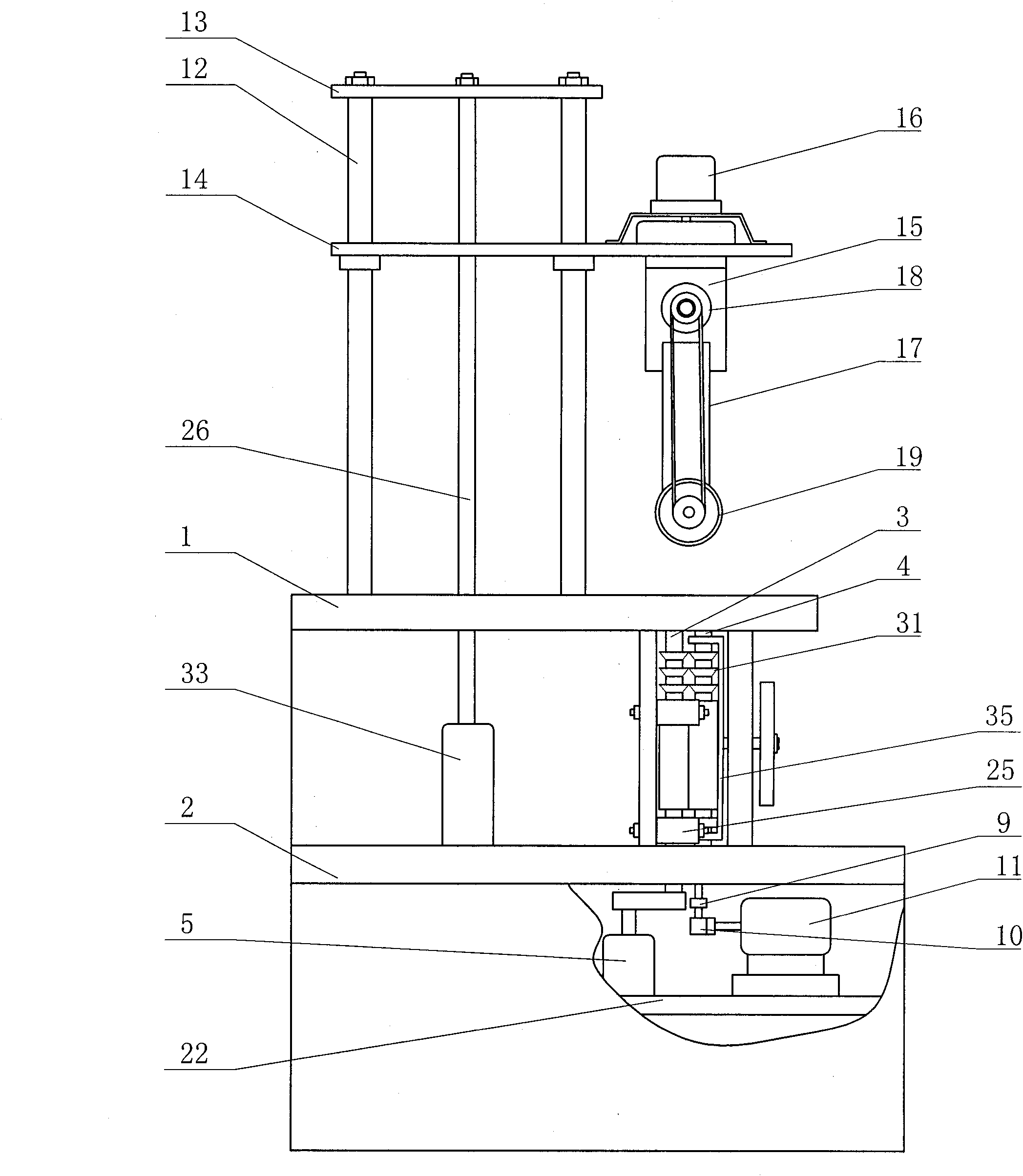

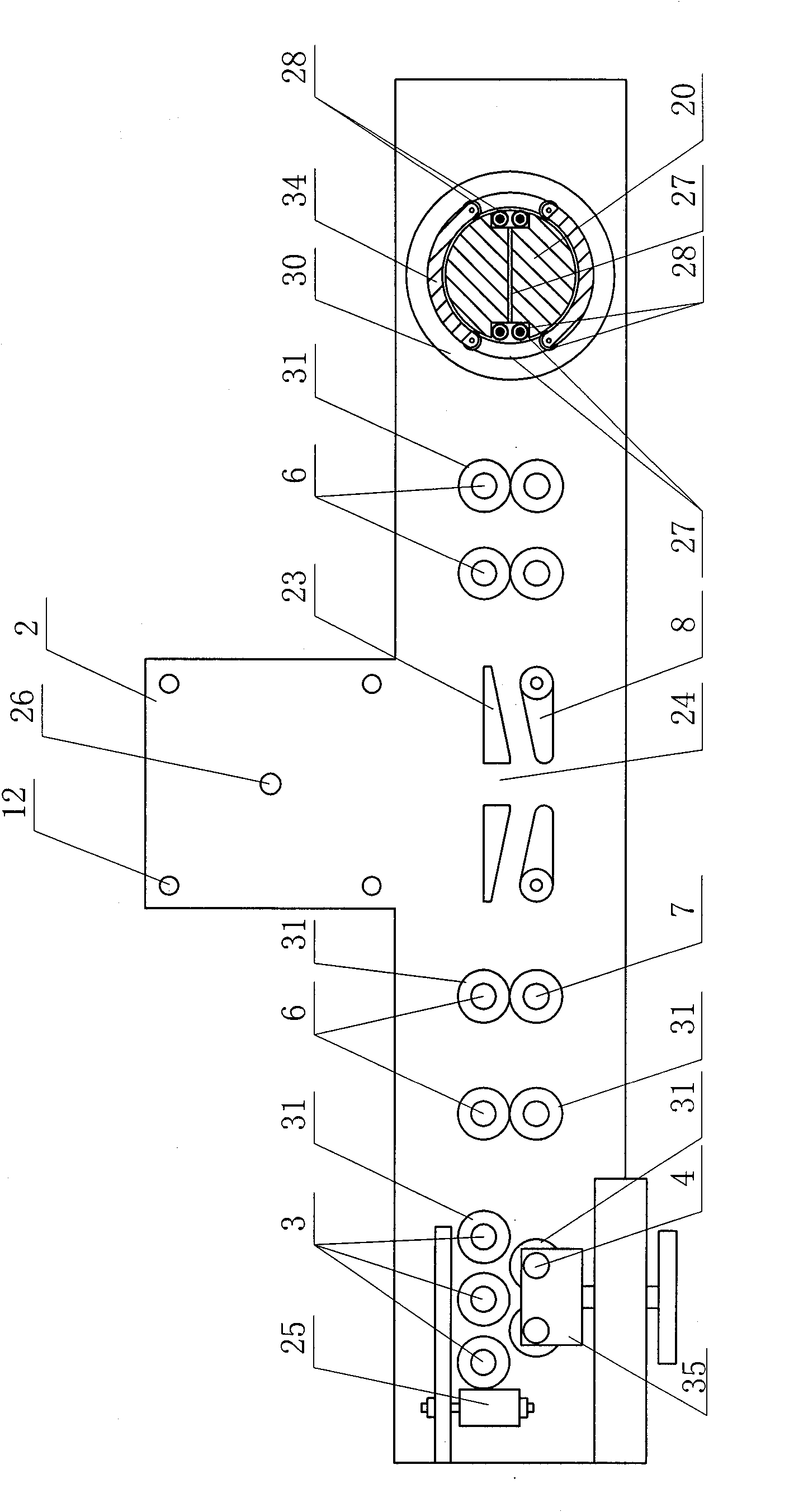

[0020] The present invention will be further described below in conjunction with accompanying drawing:

[0021] As shown in the figure, the fully automatic integrated character enclosing machine includes a sheet leveling device, a sheet conveying device, a sheet clamping device, a sheet grooving device and a sheet bending device.

[0022] The above-mentioned plank leveling device comprises an upper support plate 1, a lower support plate 2, a main flat roller 3, a driven flat roller 4 and a main motor 5, and the upper support plate 1 has a through hole for the passage of the blade 19 and Gap 21; the main flat rollers 3 are three, connected to the side between the upper support plate 1 and the lower support plate 2 through bearings, and parallel to each other left and right, the main flat rollers 3 are connected to the main motor through the belt and pulley 5 phase connection, the main motor 5 is fixed on the partition plate 22 of the machine base; the two driven flat rollers 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com