Novel pay-off frame of numerical-control winding machine

A technology of numerical control winding machine and pay-off frame, which is used in electromechanical devices, coil manufacturing, and motor-generator manufacturing, etc., can solve the problems of wire waste, incomplete wire release, and wire slack.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

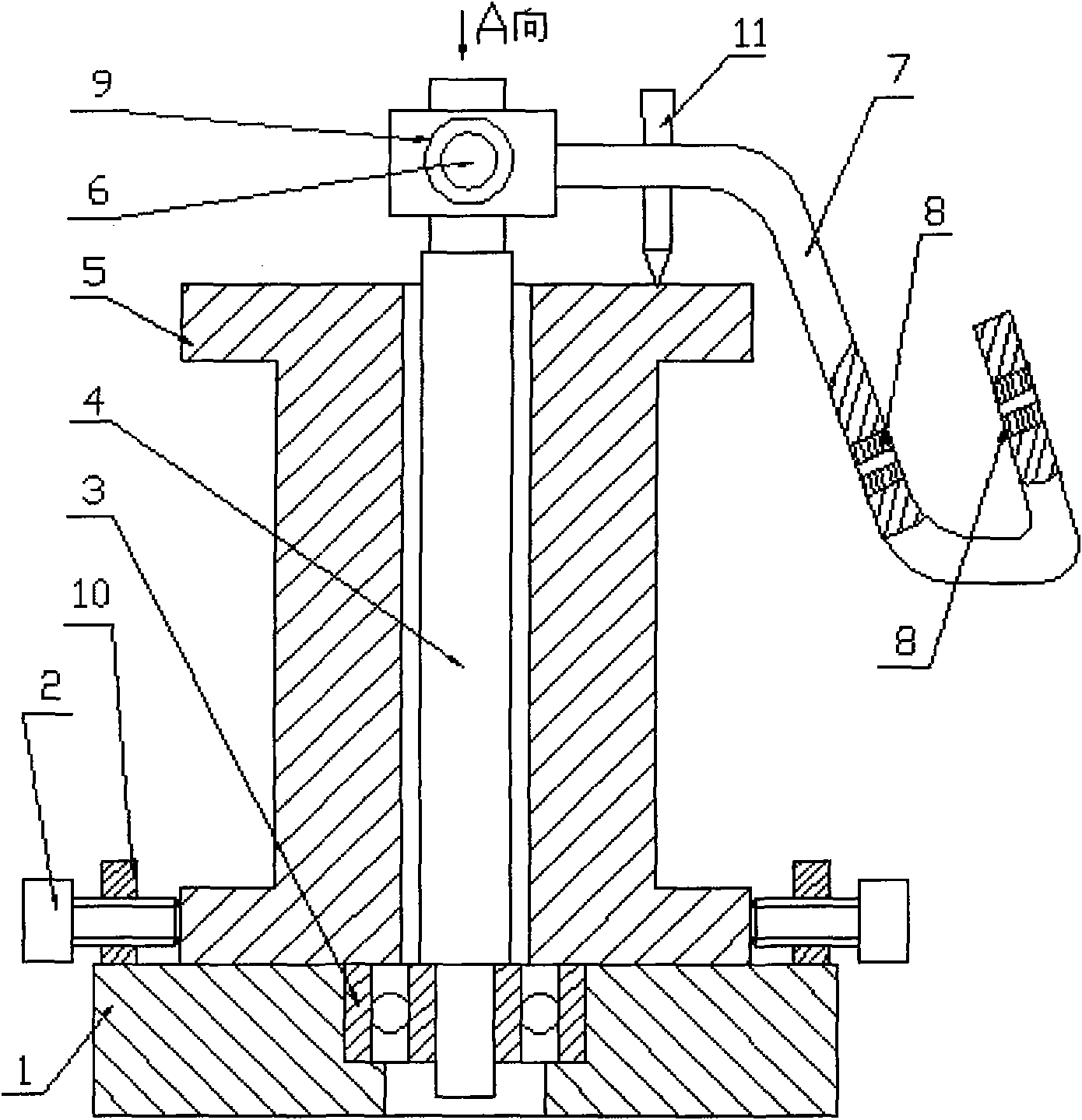

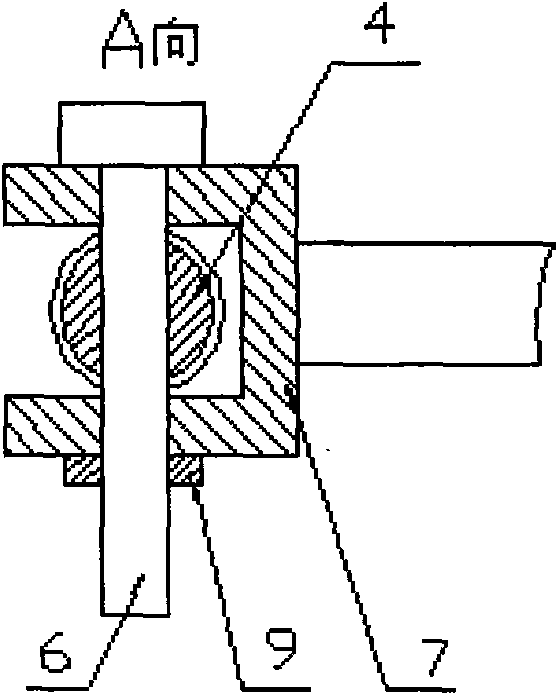

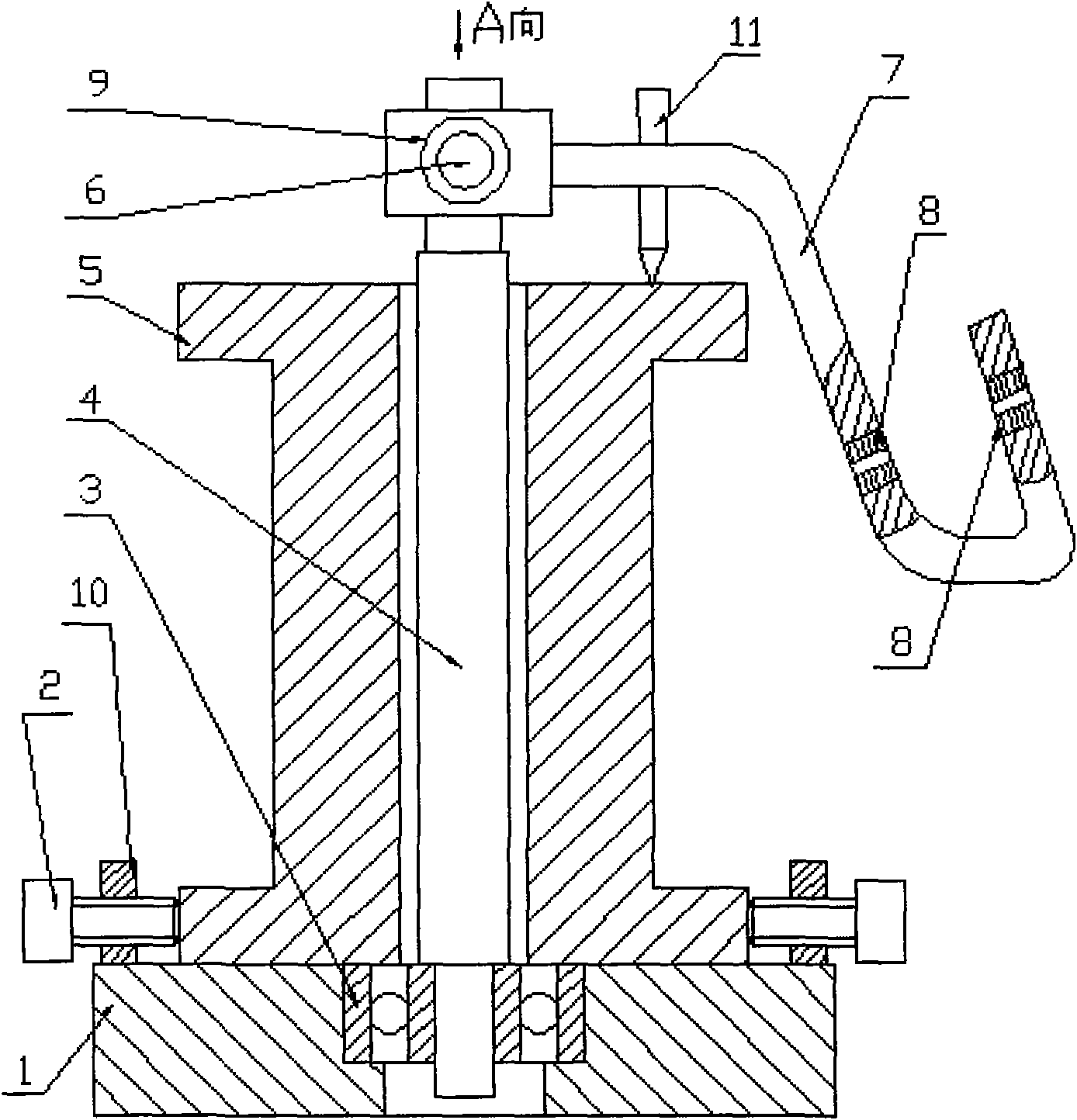

[0010] On the upper plane of the base (1) near the edge of the circumference, an appropriate number of positioning screw seats (10) are uniformly fixed, and threaded through holes are made on the described positioning screw seats (10), and the axes of the threaded through holes point to Screw in the set bolt (2) in the threaded through hole of the set screw seat (10) in the direction of the center of the base (1). Install the mandrel (4) in the central through hole of the base (1) through the bearing (3). Pass the reel of wire (5) through the mandrel (4) through the through hole in its center, place one end of the reel of wire (5) on the base (1), and at the same time, fix the The wire reel (5) is fastened. When fastening the wire reel (5), it should be ensured that the mandrel (4) does not touch the center hole of the wire reel (5), so that the mandrel (4) can Good rotational freedom. There are two through holes at the appropriate position of the bending line at the tail of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com