Rectification device for improving recovery rate

A recovery rate and rectification technology, applied in the field of rectification devices with improved precision, can solve the problems of reduced recovery rate, easy adhesion of raw materials, waste, etc., and achieve the effects of good cost, accelerated circulation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

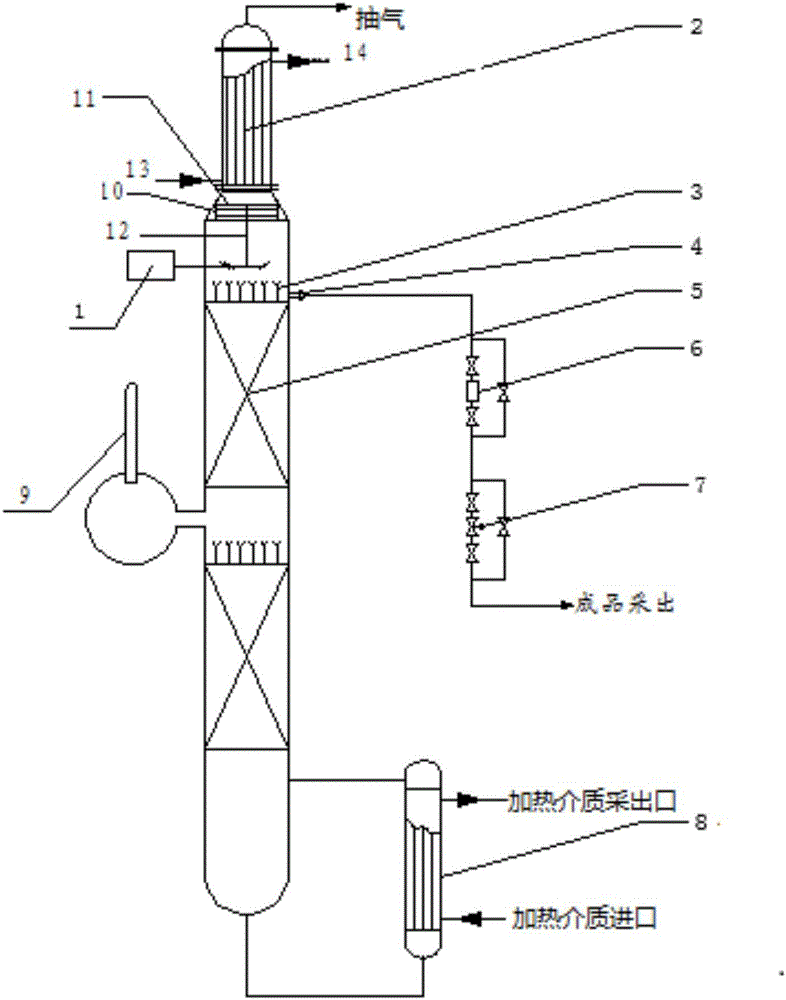

[0023] A kind of rectification device of the present invention improves recovery rate, comprises rectification tower, reboiler, tube and tube condenser, and rectification tower is provided with inlet and thermometer;

[0024] One end of the reboiler is located on one side of the rectification tower, and the other end is connected to the bottom of the rectification tower through a circulating pump;

[0025] The tube condenser is provided with a gas phase inlet, a vent, a cooling water inlet, a cooling water outlet and a condensate outlet; the gas phase inlet is connected to the gas phase pipe interface; the condensate outlet is connected to a liquid distributor;

[0026] The upper part of the rectification tower is provided with a gas guide tube near the gas phase pipe interface, a smooth rotating shaft arranged in the guide tube and a plurality of guide vanes fixed on the smooth shaft, and the guide tube is vertical Placed circular tube with a smooth and flat inner wall, the d...

Embodiment 2

[0031] A rectification device for improving the recovery rate of the present invention comprises a rectification tower, a reboiler and a tube condenser,

[0032] The rectification tower is equipped with a feed inlet and a thermometer;

[0033] One end of the reboiler is located on one side of the rectification tower, and the other end is connected to the bottom of the rectification tower through a circulating pump;

[0034] The tube condenser is provided with a gas phase inlet, a vent, a cooling water inlet, a cooling water outlet and a condensate outlet; the gas phase inlet is connected to the gas phase pipe interface; the condensate outlet is connected to a liquid distributor;

[0035] The upper part of the rectification tower is provided with a gas guide tube near the gas phase pipe interface, a smooth rotating shaft arranged in the guide tube and a plurality of guide vanes fixed on the smooth shaft, and the guide tube is vertical Placed circular tube with a smooth and fla...

Embodiment 3

[0040] A rectification device for improving the recovery rate of the present invention comprises a rectification tower, a reboiler and a tube condenser,

[0041] The rectification tower is equipped with a feed inlet and a thermometer;

[0042] One end of the reboiler is located on one side of the rectification tower, and the other end is connected to the bottom of the rectification tower through a circulation pump;

[0043] The tube condenser is provided with a gas phase inlet, a vent, a cooling water inlet, a cooling water outlet and a condensate outlet; the gas phase inlet is connected to the gas phase pipe interface; the condensate outlet is connected to a liquid distributor;

[0044] The upper part of the rectification tower is provided with a gas guide tube near the gas phase pipe interface, a smooth shaft arranged in the guide tube and a plurality of guide vanes fixed on the smooth shaft, and the guide tube is vertical Placed circular cylinder with a smooth and flat inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com