Light distribution method of profiled microprism LED (Light-Emitting Diode) fluorescent lamp tube

A technology of LED fluorescent lamps and LED lamp beads, applied in the direction of light source, light source fixed, point light source, etc., can solve the problems of product brightness reduction, visual fatigue, mercury pollution environment, etc., to improve LED light output rate, eliminate light spots and glare Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

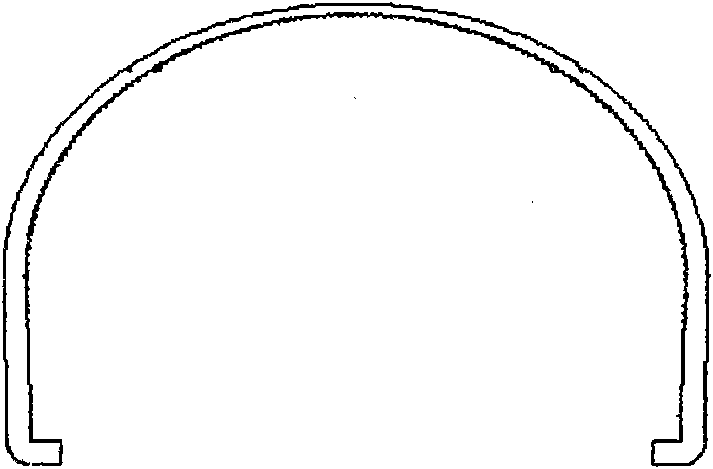

[0032] see Figure 6 The cross-sectional view of the LED fluorescent tube of Embodiment 1, the distance between the lamp beads L=5.65MM, the distance H=1.4L=7.9MM from the upper surface of the LED to the highest point on the inner surface of the PC cover, and the diameter R=0.4MM of the dimple lens.

[0033] Figure 9 A is the effect diagram of refracted light when H=1.4L.

Embodiment 2

[0035] see Figure 7 The cross-sectional view of the LED fluorescent tube of embodiment 2, the distance between the lamp beads L=5.43MM, the distance H=2.5L=13.6MM from the upper surface of the LED to the highest point on the inner surface of the PC cover, and the diameter R=0.4MM of the dimple lens.

[0036] Figure 9 B is the effect diagram of refracted light when H=2.5L.

Embodiment 3

[0038] see Figure 8 The cross-sectional view of the LED fluorescent tube of Embodiment 3, the distance between the lamp beads L=4.84MM, the distance H=3.0L=14.5MM from the upper surface of the LED to the highest point on the inner surface of the PC cover, and the diameter R=0.4MM of the dimple lens.

[0039] Figure 9 C is the effect diagram of refracted light when H=3.0L.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap