Hot water boiler with large-capacity water tubes

A hot water boiler and large-capacity technology, applied in the field of hot water boilers, can solve the problems of low-temperature corrosion, ash accumulation at the flue gas outlet, and limit the length and width of the boiler, achieving high heat transfer efficiency, high economic benefits, and less hidden dangers of accidents. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

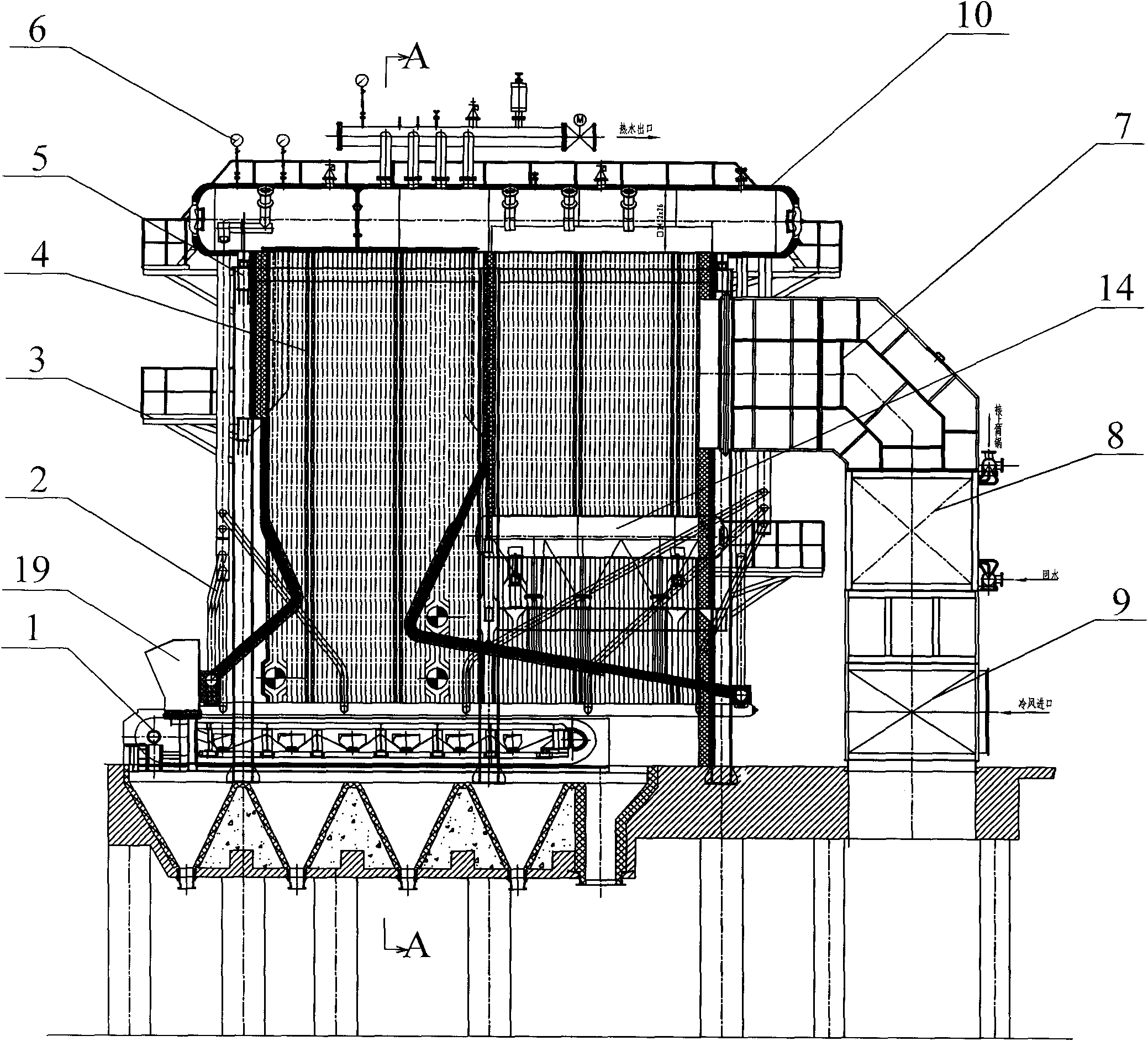

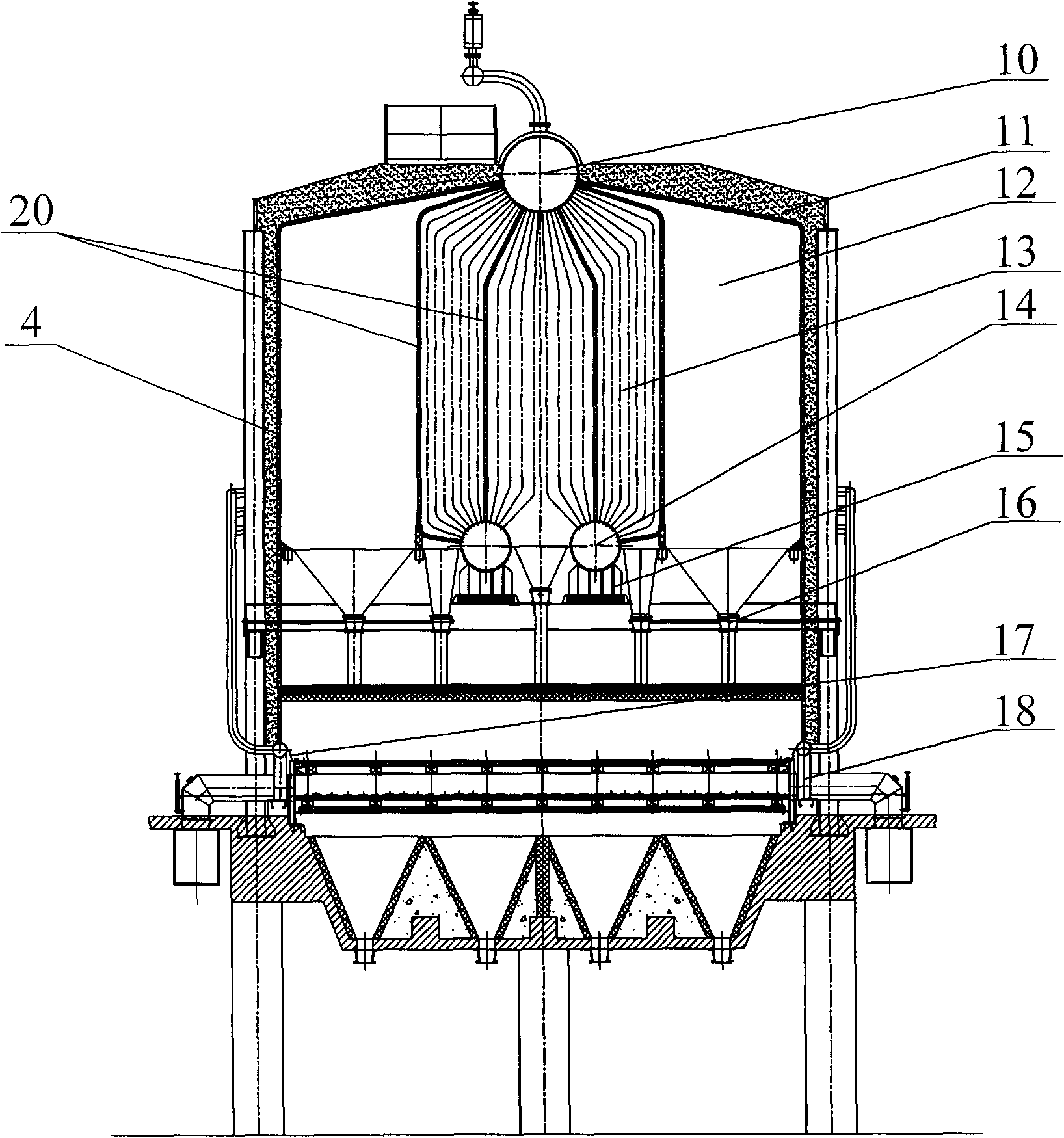

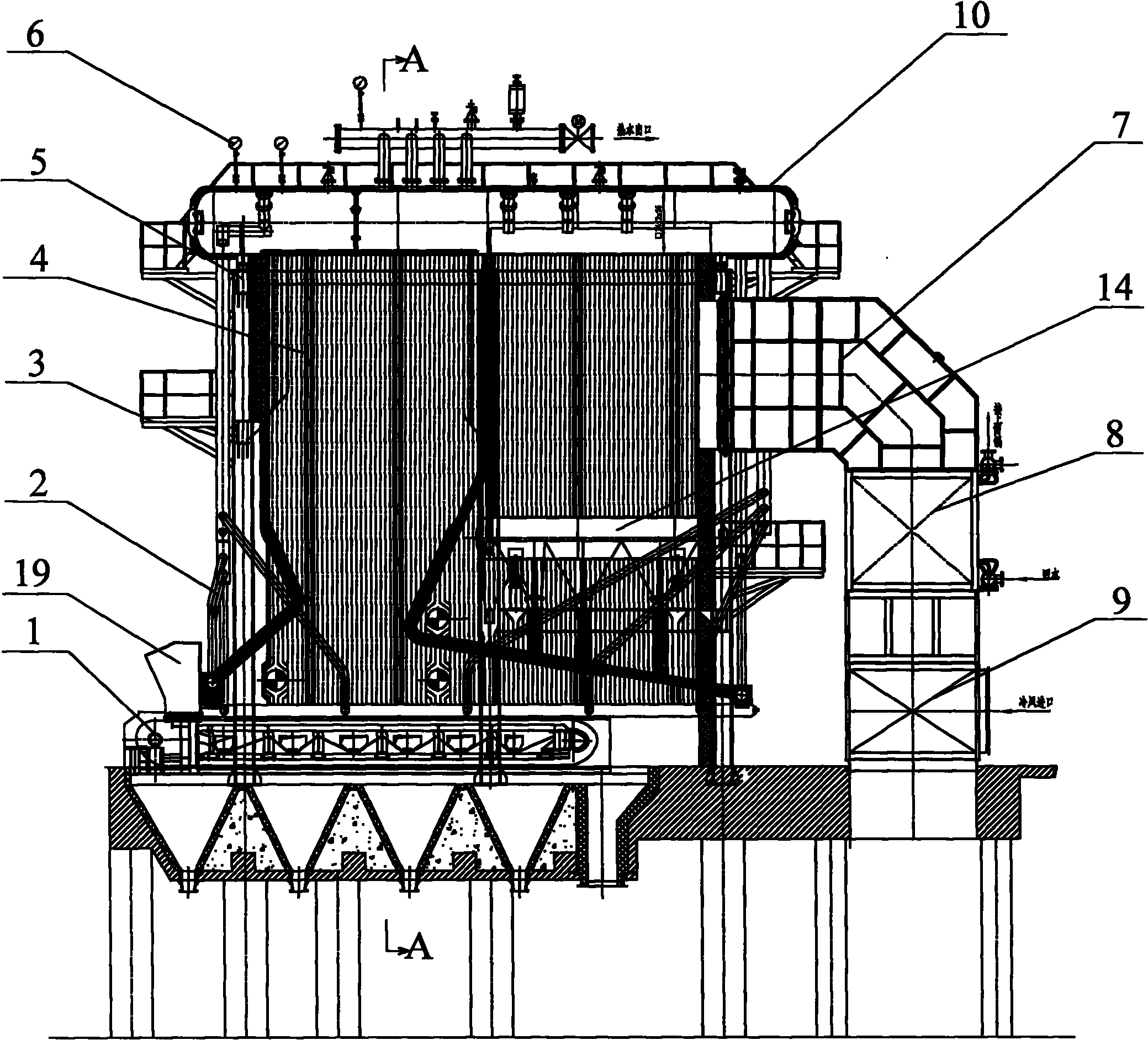

[0010] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0011] As shown in the figure, the present invention mainly consists of combustion equipment 1, downpipe 2, platform escalator 3, furnace water wall 4, steel frame 5, instrument valve 6, flue 7, economizer 8, air preheater 9, upper Drum 10, holding furnace wall 11, ember chamber 12, convection tube bundle 13, lower drum 14, lower drum support 15, ash falling device 16, sealing device 17, body support 18, coal hopper 19 and convection tube Devices such as membrane wall 20 constitute.

[0012] The large-capacity water tube hot water boiler includes a furnace water-cooled wall 4 and a heat-retaining furnace wall 11 arranged on a body support 18. A sealing device 17 is provided at the connection between the body support 18 and the heat-retaining furnace wall 11. Combustion equipment 1 is installed, and a coal hopper 19 is installed on the combustion equipment 1. A...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap