Grate plate arrangement

A grid plate and grid technology, which is applied in the field of grid plate devices, can solve problems such as non-compliance with bolt pre-tightening force, and achieve the effect of preventing contact and preventing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

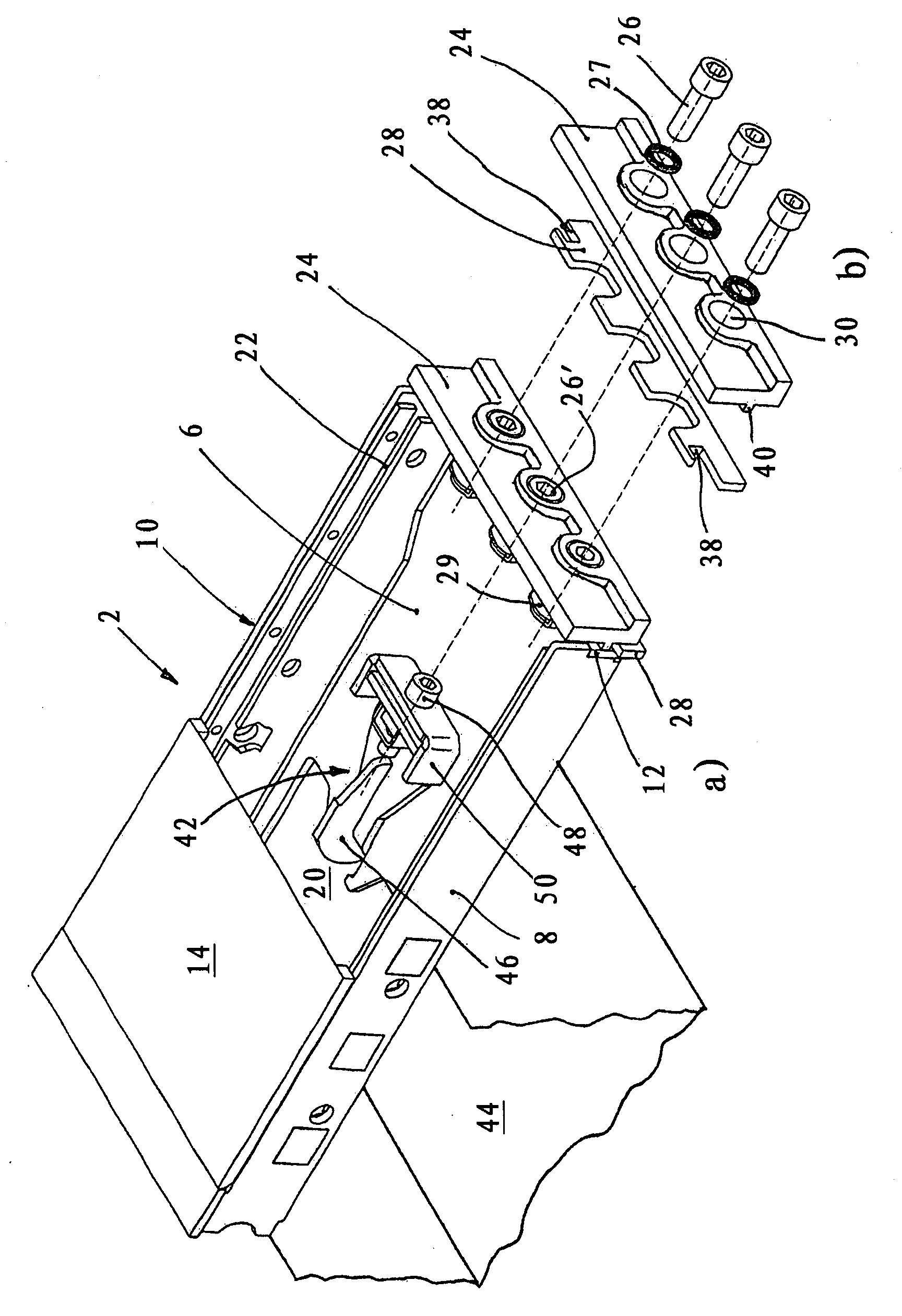

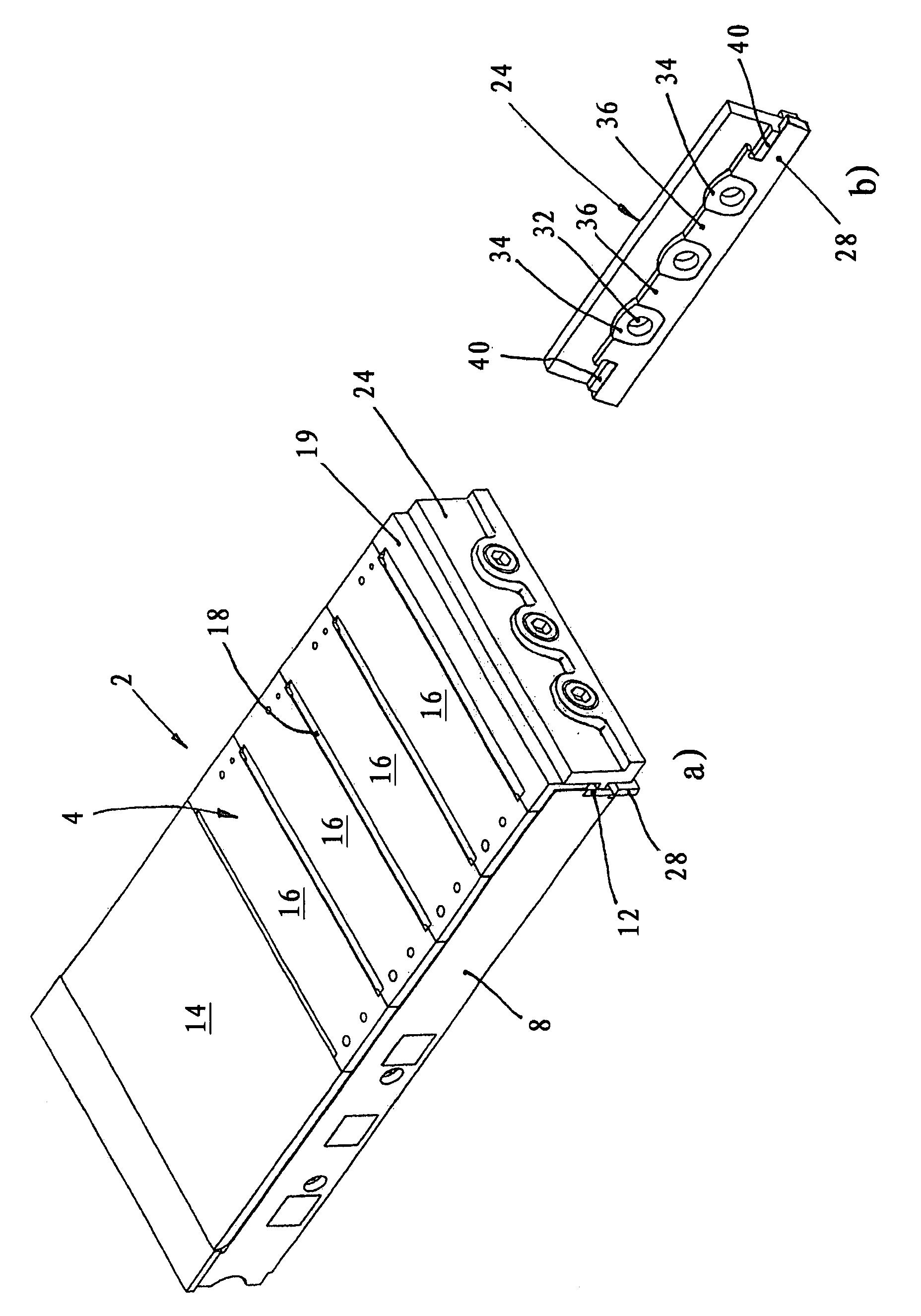

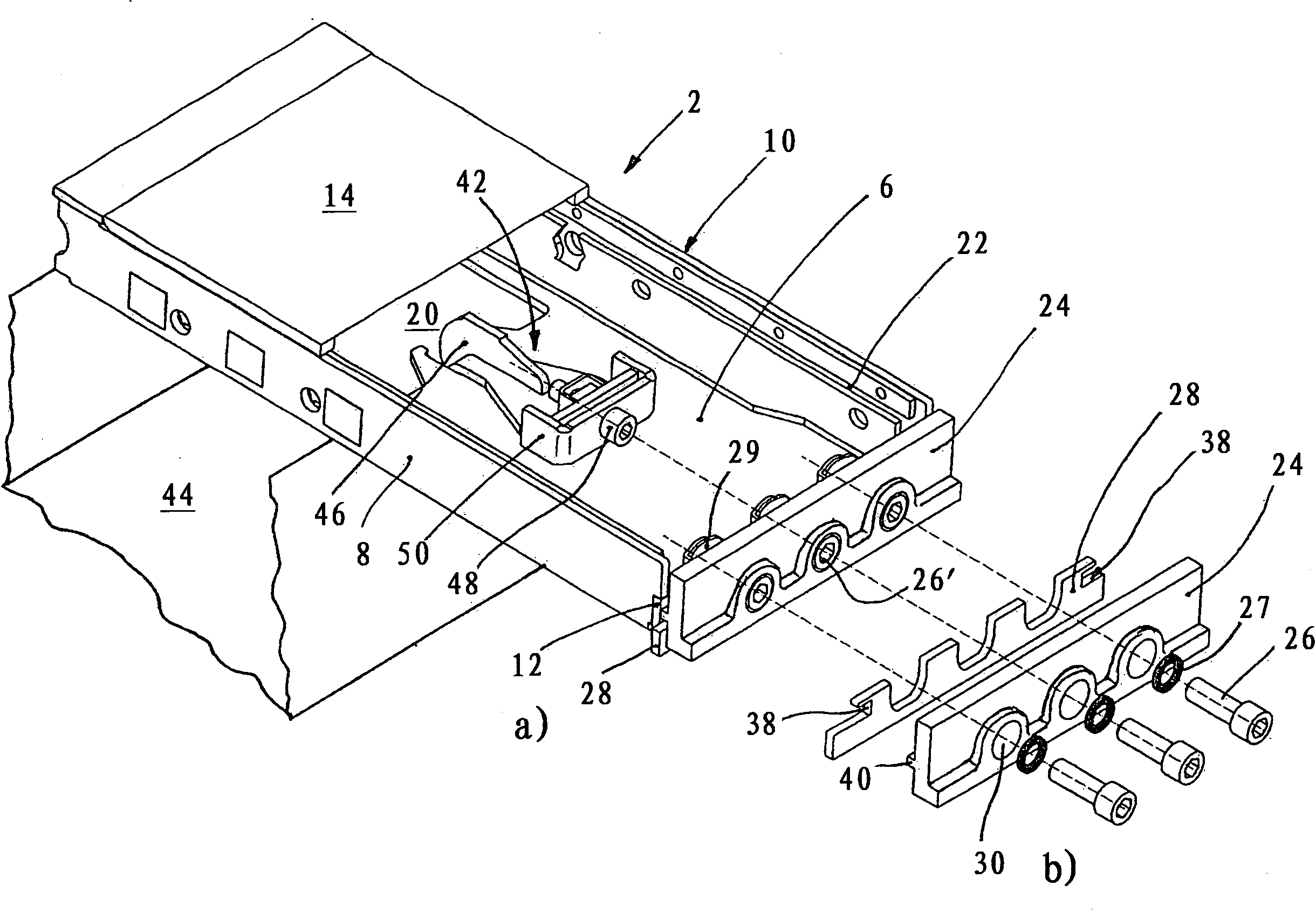

[0027] exist figure 1 The grid panels 2 shown in a and 2a have a substantially conventional construction. It is approximately box-shaped and comprises a cover wall 4 , a bottom wall 6 , two side walls 8 , 10 , a rear wall not visible in the drawing, and a front wall 12 .

[0028] as special figure 2 It can be seen that the cover wall 4 basically comprises: a closed starting sheet 14, which roughly corresponds to an overlapping region with a front not shown grid sheet; a plurality of intermediate sheets 16, between which respectively There remains a blowing slit; and a curved end sheet 19 which constitutes the closure of the cover wall 4 with the upper region of the front wall 12 .

[0029] In its rear region, the bottom wall 6 has an opening 20 , through which it rests on a grill support 44 , through which opening, for example, cooling air is introduced into the grill plate.

[0030] The cooling air flows through the blowing slits 18 into the bulk material lying on the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com