Polarized light emitting device

A technology of light-emitting devices and light polarization, which is applied in semiconductor devices, electrical components, circuits, etc., and can solve problems such as insufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

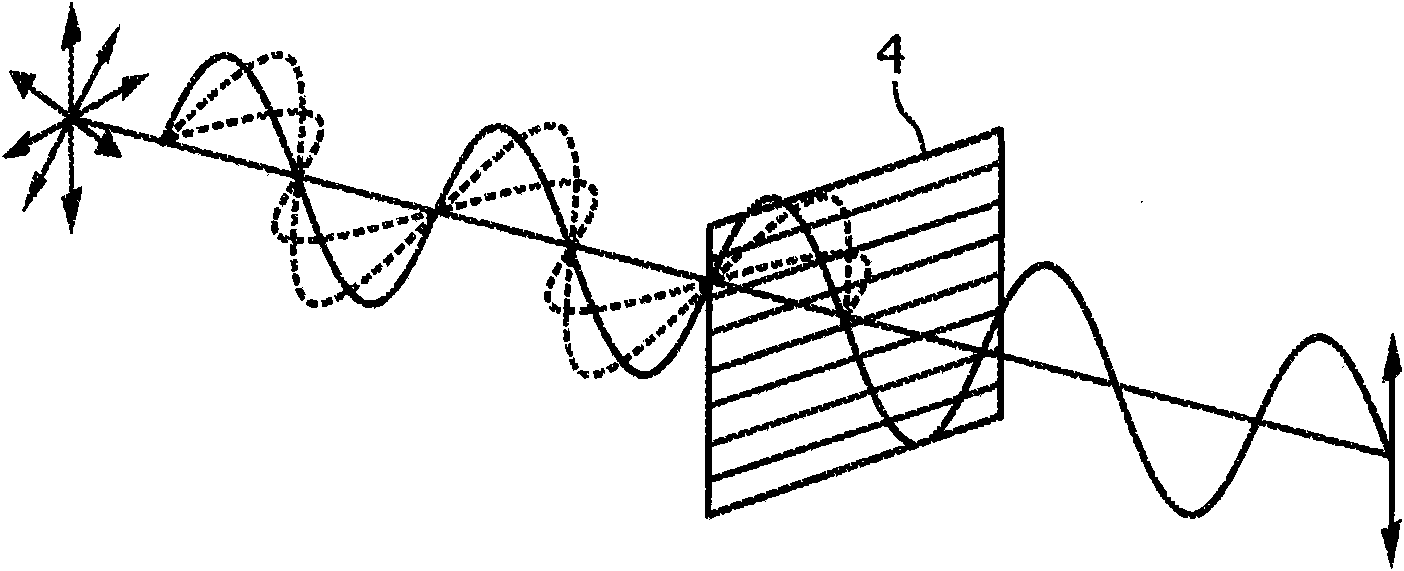

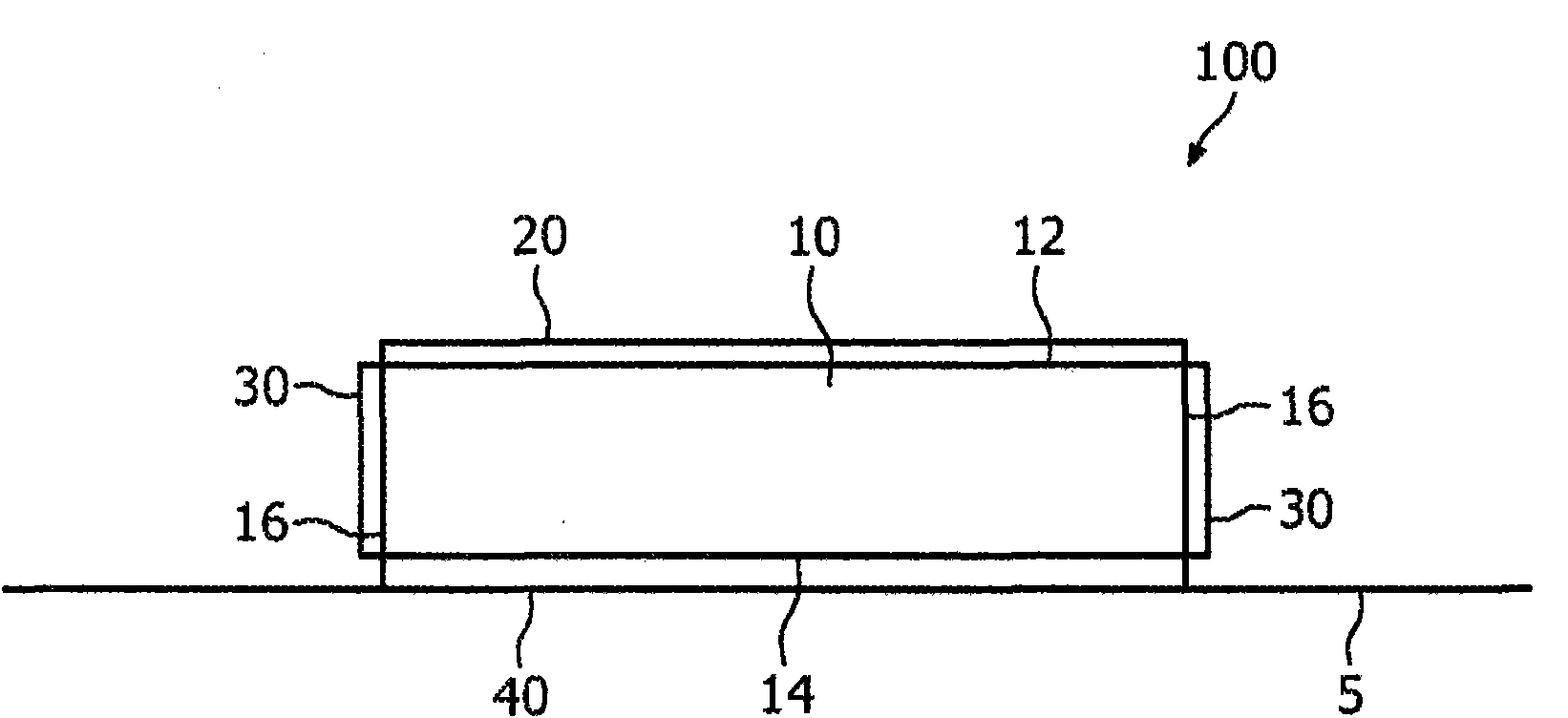

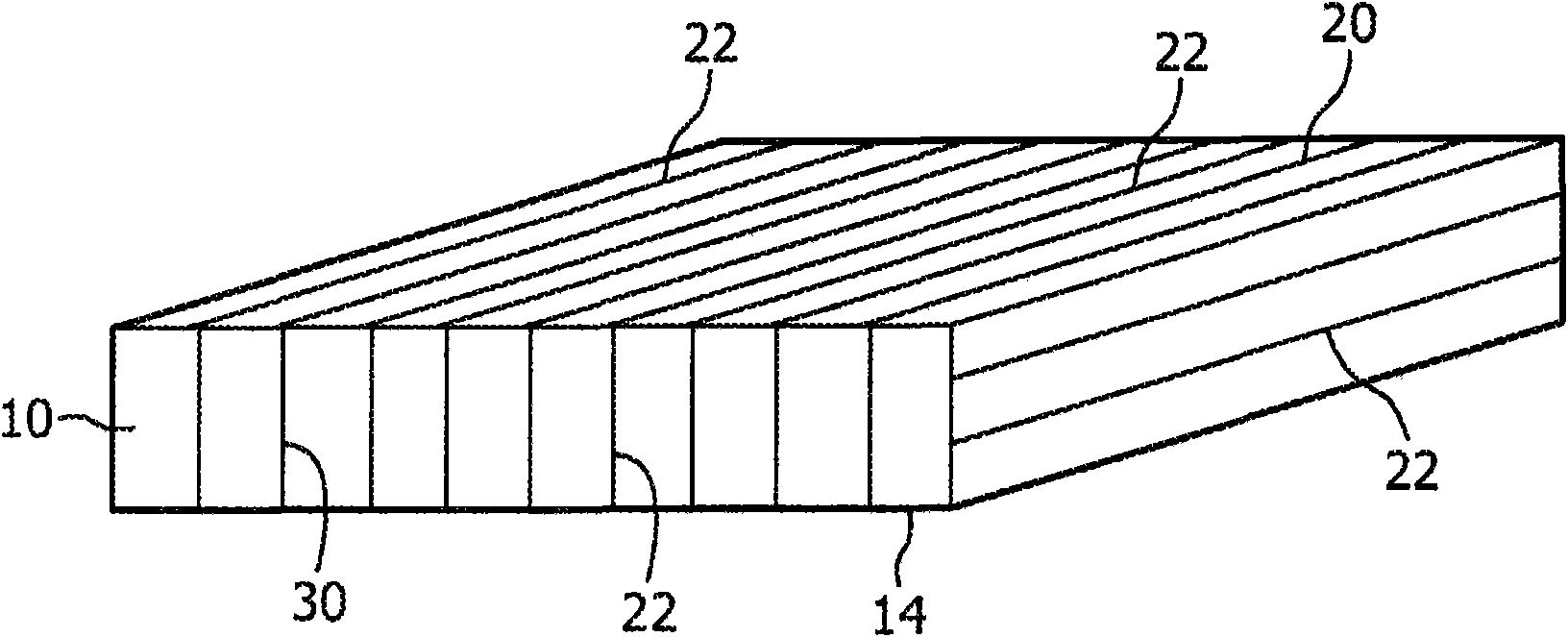

[0031] exist figure 1 , the basic principle of the polarizing element is shown. The propagating light waves shown are incident on the polarizing element 4 . This light wave, which does not have a specific polarization state indicated by the solid and dashed lines, is transmitted through the polarizing element 4 . However, only a portion of the light wave having a certain polarization state is transmitted, as shown by the solid line. Other parts of this light wave are reflected back or absorbed by the polarizing element 4 .

[0032] Such as figure 1 As shown, the polarizing element 4 is a grating with a plurality of slits arranged in parallel. The grating period is smaller than the wavelength of the light wave. Such polarizing elements are known as wire grid polarizers. Wire grid polarizers typically consist of small strips of metal, such as aluminum, separated by air or a dielectric material. The grating period is typically on the order of 100-200 nm. A typical duty ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com