Differential type extruder and molding technique thereof

An extruder and differential technology, which is applied in the field of extruder and its molding process, can solve the problems that the product is difficult to extrude stably, cannot work normally, and the accuracy of the product is difficult to ensure, and achieves the melt pressure and is stable and easy to use. The effect of limited life and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

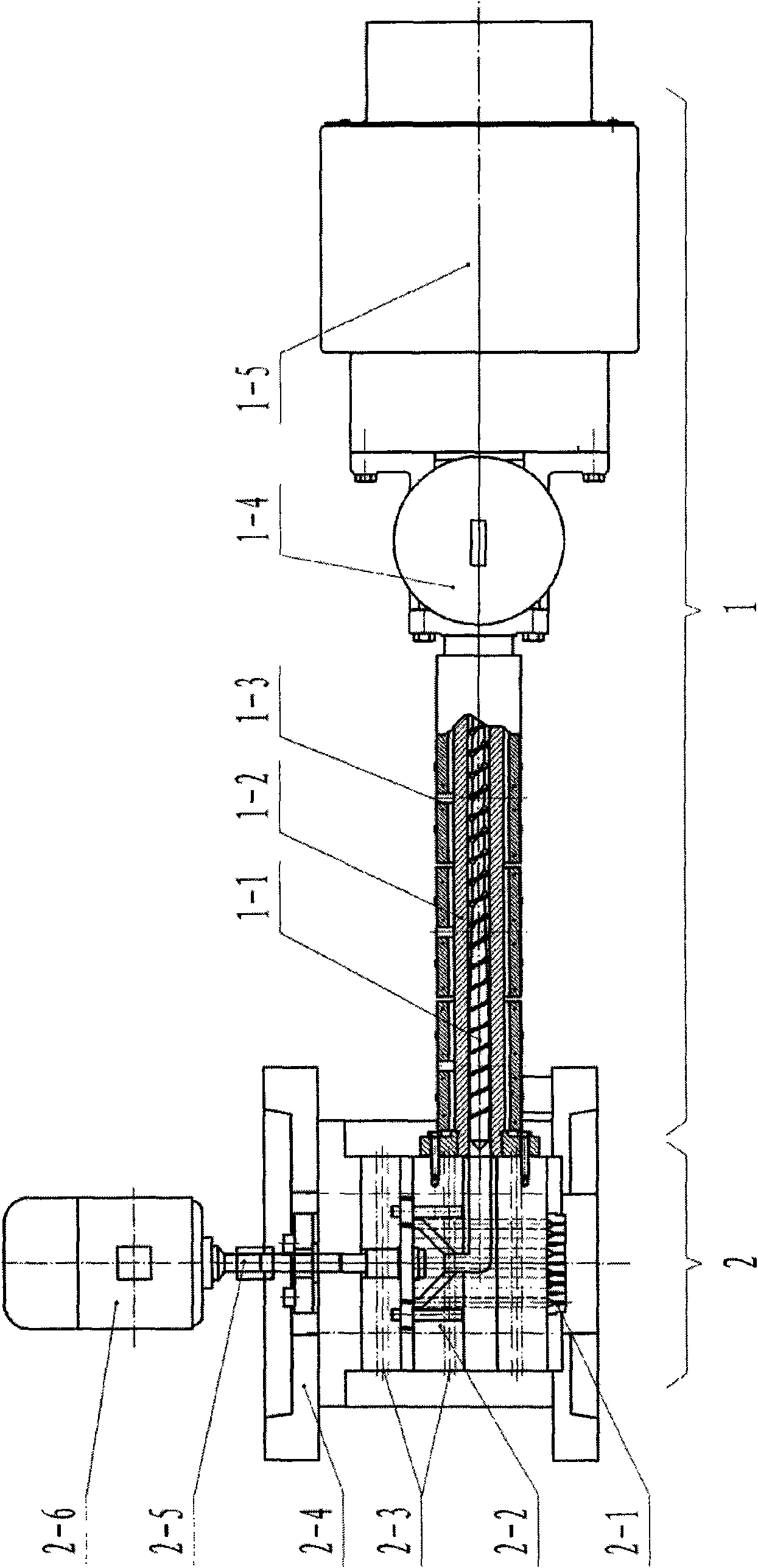

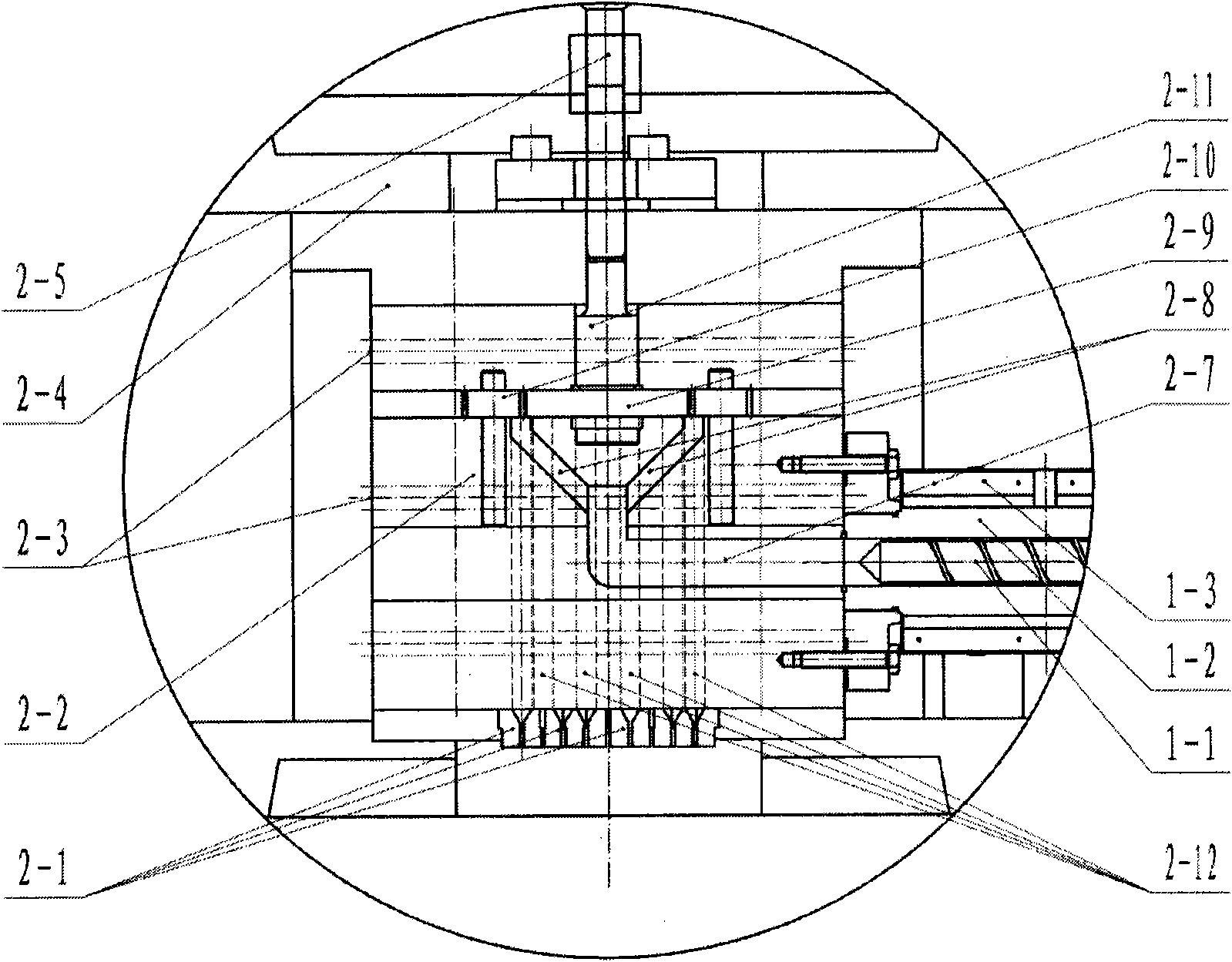

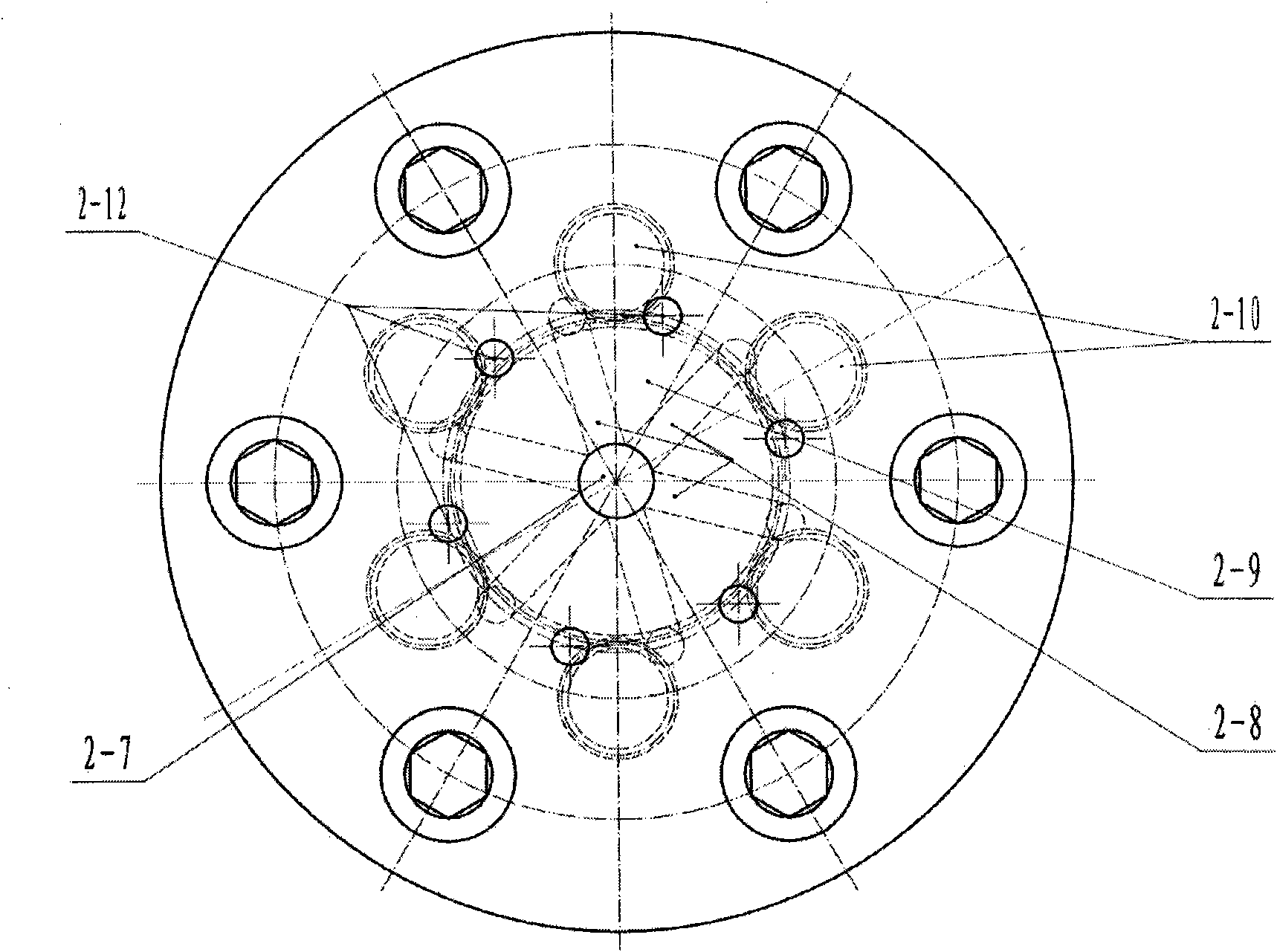

[0020] Differential extruder of the present invention such as figure 1 , figure 2 , image 3 As shown, it is mainly composed of an extrusion system (1) and a metering and splitting system (2). The extrusion system (1) is the same as that of a conventional extruder, mainly including a screw (1-1), a barrel (1-2) , heating and cooling system (1-3), feeding device (1-4), and transmission system (1-5); metering and splitting system (2) includes planetary gear pump (2-2), support (2-4) , shaft coupling (2-5), rotation control device (2-6), temperature control device (2-3), metering and splitting system (2) is set at the outlet end of extrusion system (1), and rotation control device (2 -6) The output shaft is connected with the driving gear shaft (2-11) of the planetary gear pump (2-2) through a coupling (2-5), and the planetary gear pump (2-2) has a main inlet (2-7 ) and multiple outlets (2-12), the main inlet (2-7) is connected to multiple inlet branches (2-8), and each inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com