Simulated wind pressure detection device and method for elevator door system

A detection device, elevator door technology, applied in the measurement device, the measurement of fluid pressure through electromagnetic components, transportation and packaging, etc. Wide range, small error, and the effect of reducing failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

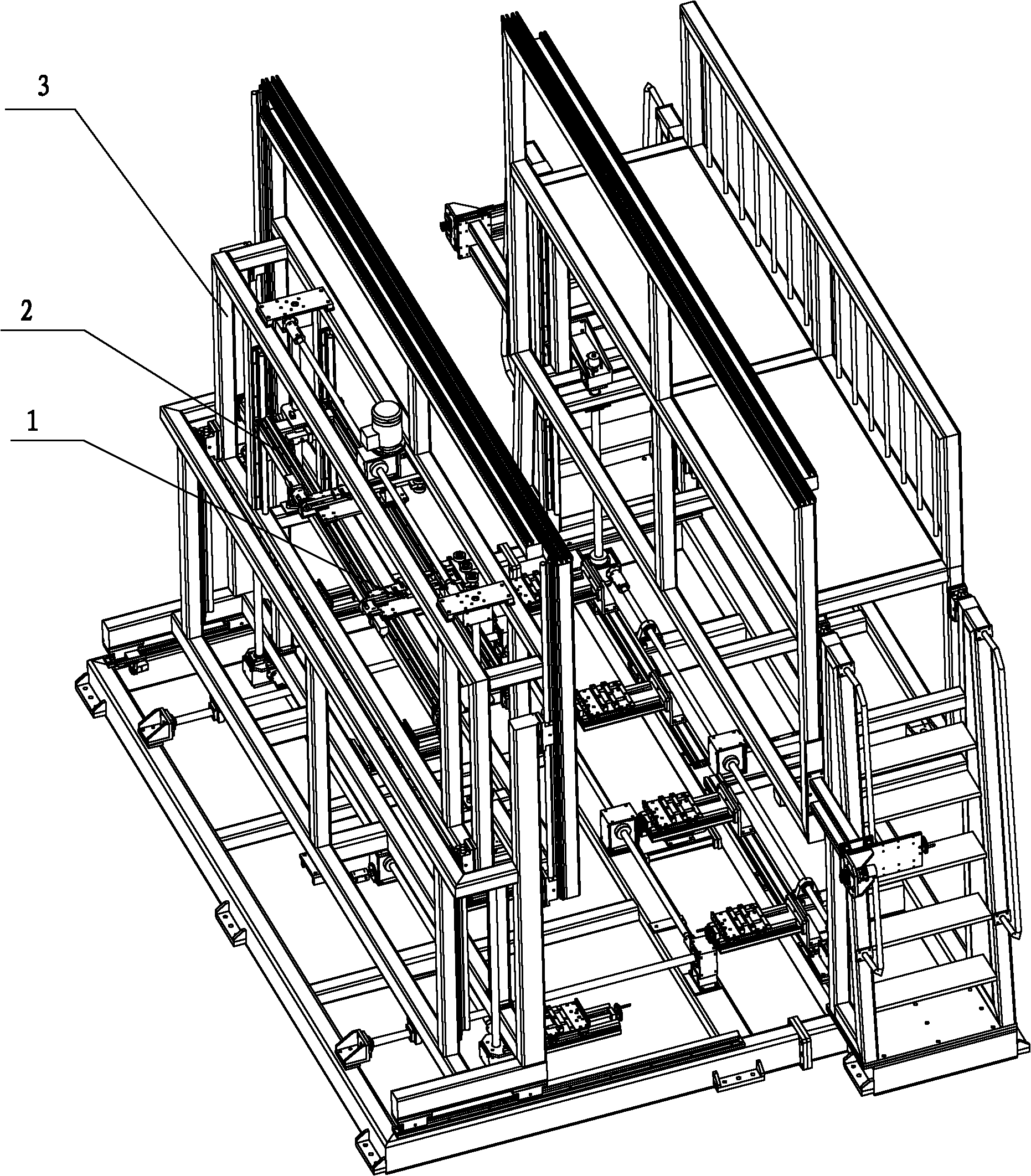

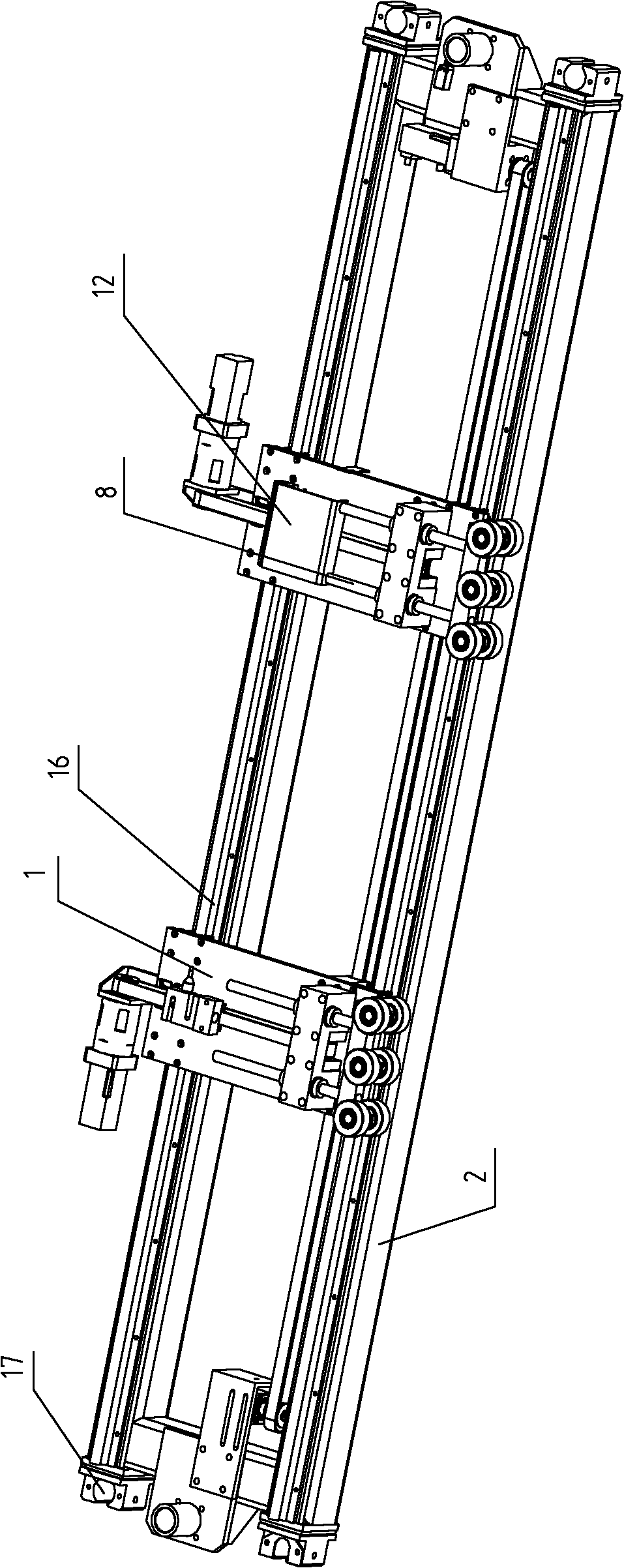

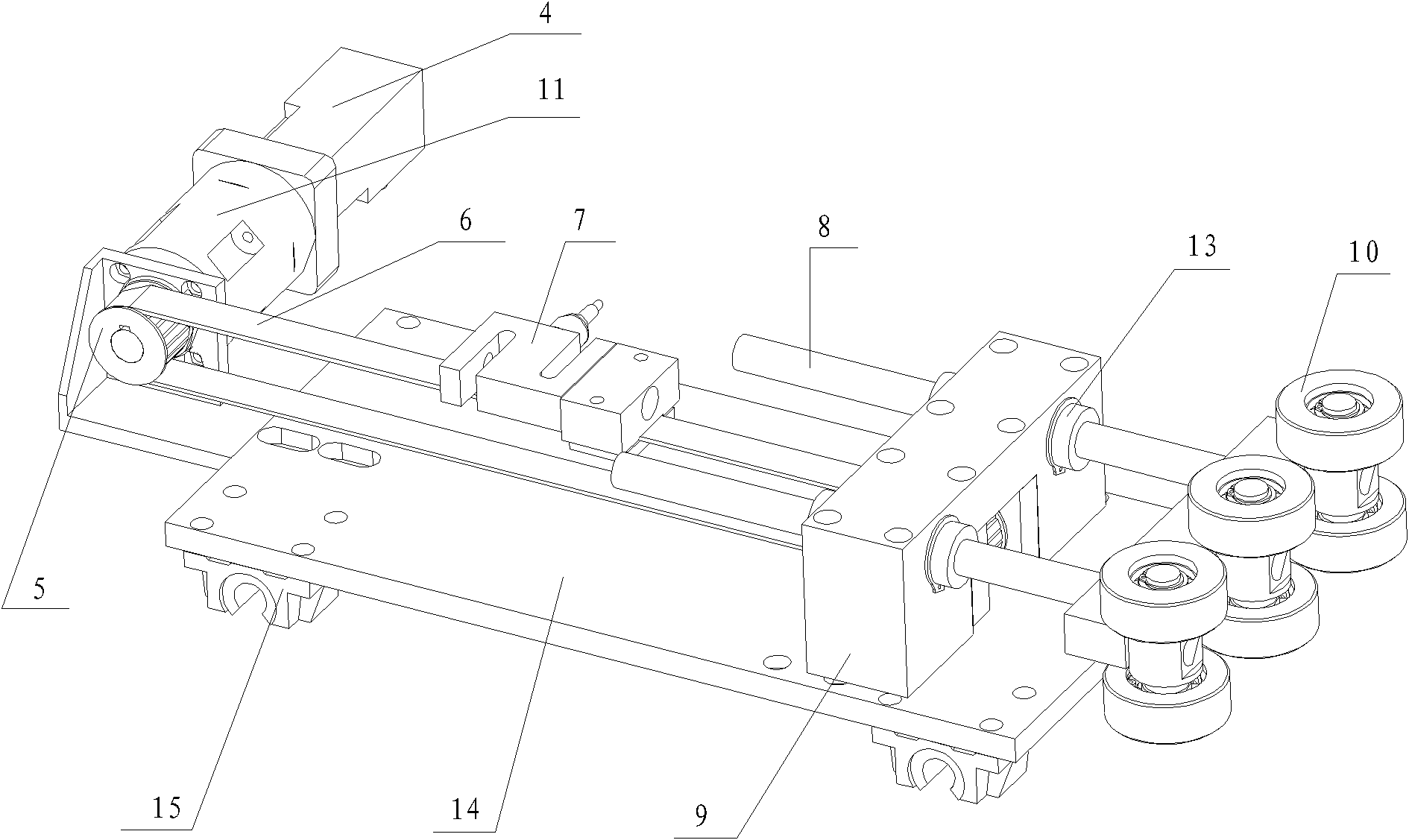

[0035] In this embodiment, a simulated wind pressure detection device for elevator door system, such as figure 1 or figure 2 As shown, it includes at least two detection cars 1 and a detection control unit, each detection car 1 is electrically connected to the detection control unit, and each detection car 1 is respectively set on the floor door installation frame 3 through the wind pressure simulation frame 2; any detection The structure of trolley 1 is as follows image 3 As shown, it includes trolley drive motor 4, transmission wheel 5, transmission belt 6, tension sensor 7, linear guide rail 8, fixed seat 9 and landing door contact block 10, trolley drive motor 4 is connected with transmission wheel 5 through reducer 11, and transmission The wheel 5 cooperates with the transmission belt 6, the tension sensor 7 is fixed on the transmission belt 6, one end of the linear guide rail 8 is fixedly connected with the tension sensor 7 through a fixed block 12, the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com