Electrical junction box

A technology of electrical junction box, attachment, applied in the direction of conductive connection, circuit, connection, etc., which can solve the problems of increased production cost, increased number of parts, impossibility to prevent water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The configuration of the present invention for solving the above-mentioned problems will be described below. It should be noted that constituent elements employed in the following configurations can be freely combined with each other as much as possible.

[0043] In order to explain the present invention in more detail, an embodiment of an electrical junction box according to the present invention will now be described hereinafter with reference to the accompanying drawings.

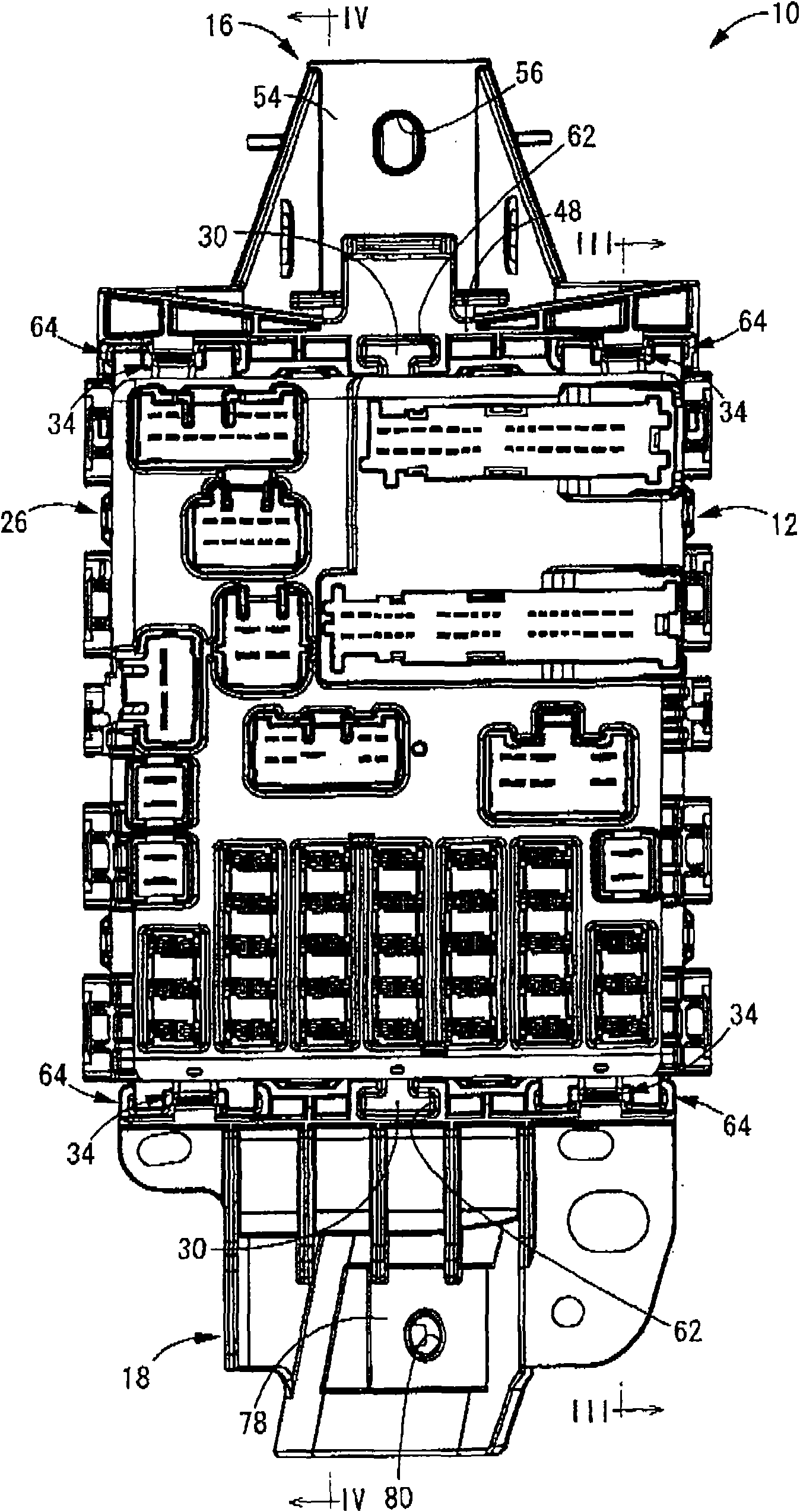

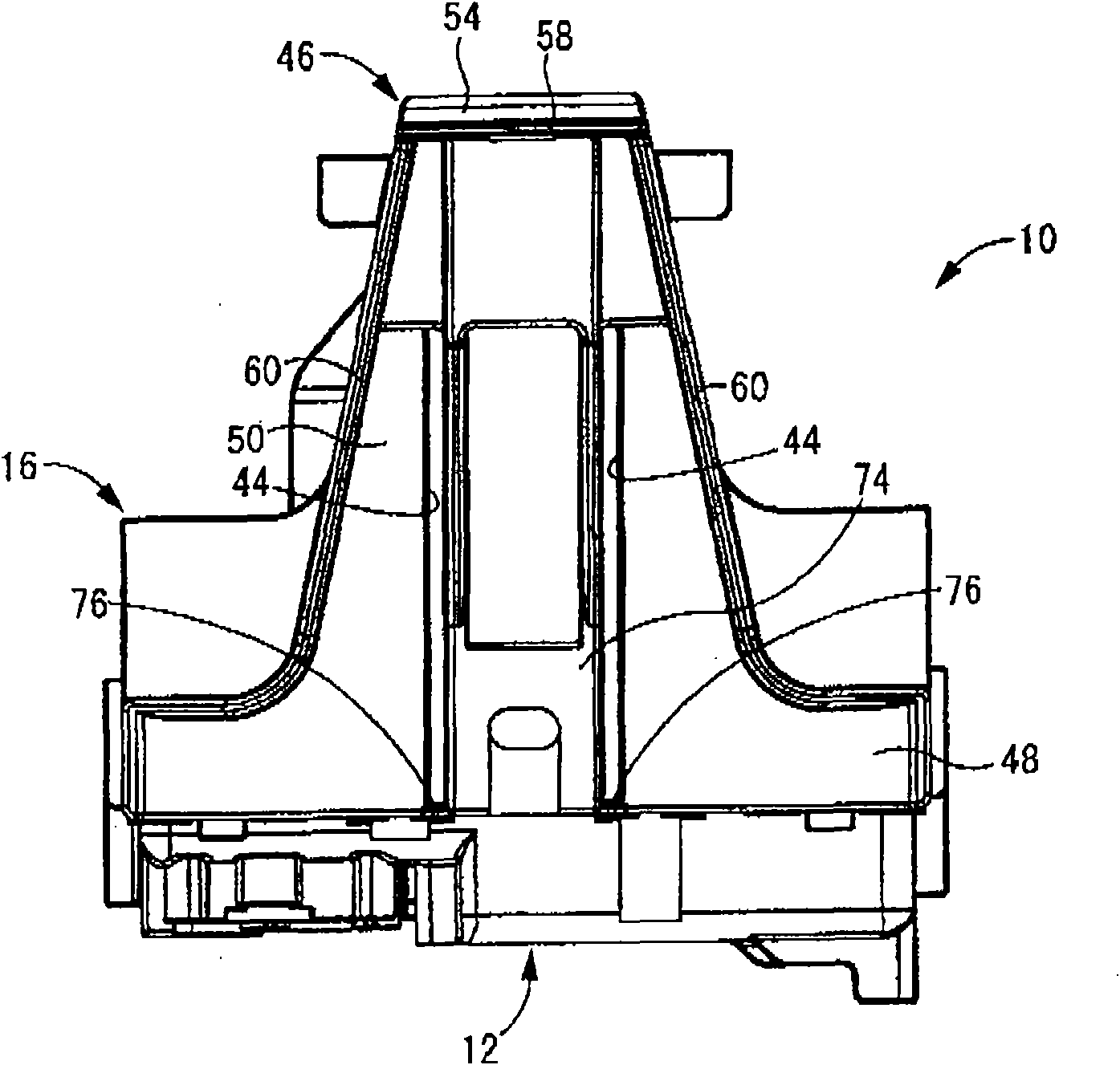

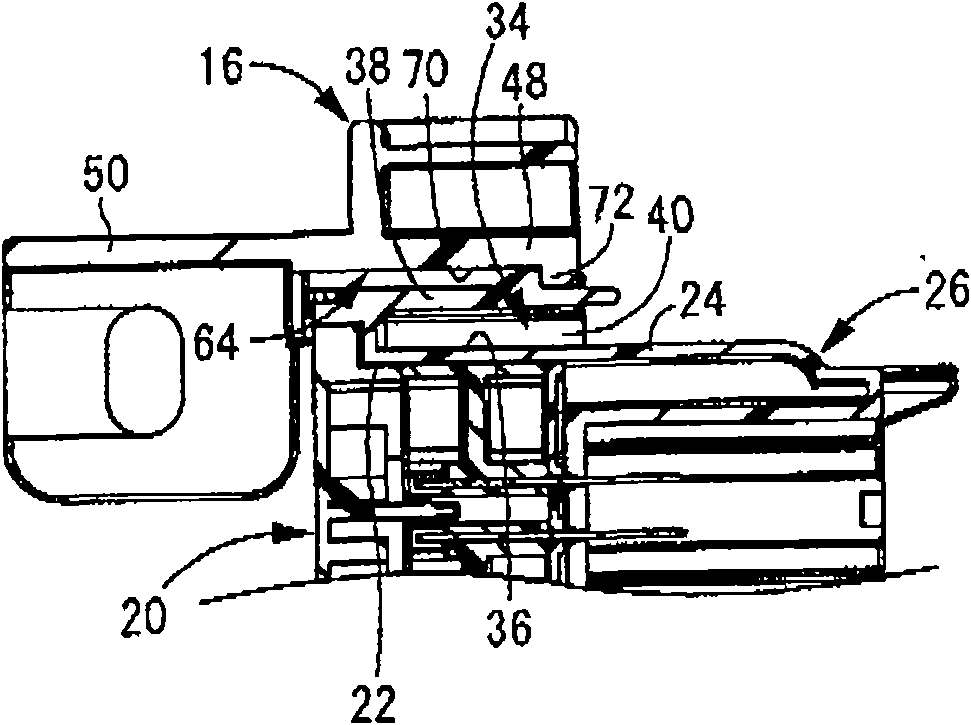

[0044] Figures 1 to 4 An electrical junction box 10 in one embodiment of the present invention is shown. This electrical junction box 10 is a vertical installation type electrical junction box in which an electrical junction box body 12 is attached to a vehicle body panel 14 by two brackets 16 and 18 serving as attachment legs (see Figure 4 ), and the electrical junction box body 12 is opposed to the vertical wall portion of the vehicle body panel 14. In principle, in the following, figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com