Heating cartridge for thermostatic element and method for manufacturing same, as well as thermostatic valve comprising such a cartridge

A technology for constant temperature elements and heating cylinders, applied in heating elements, temperature control, engine elements, etc., can solve problems such as difficult implementation and unacceptable molding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

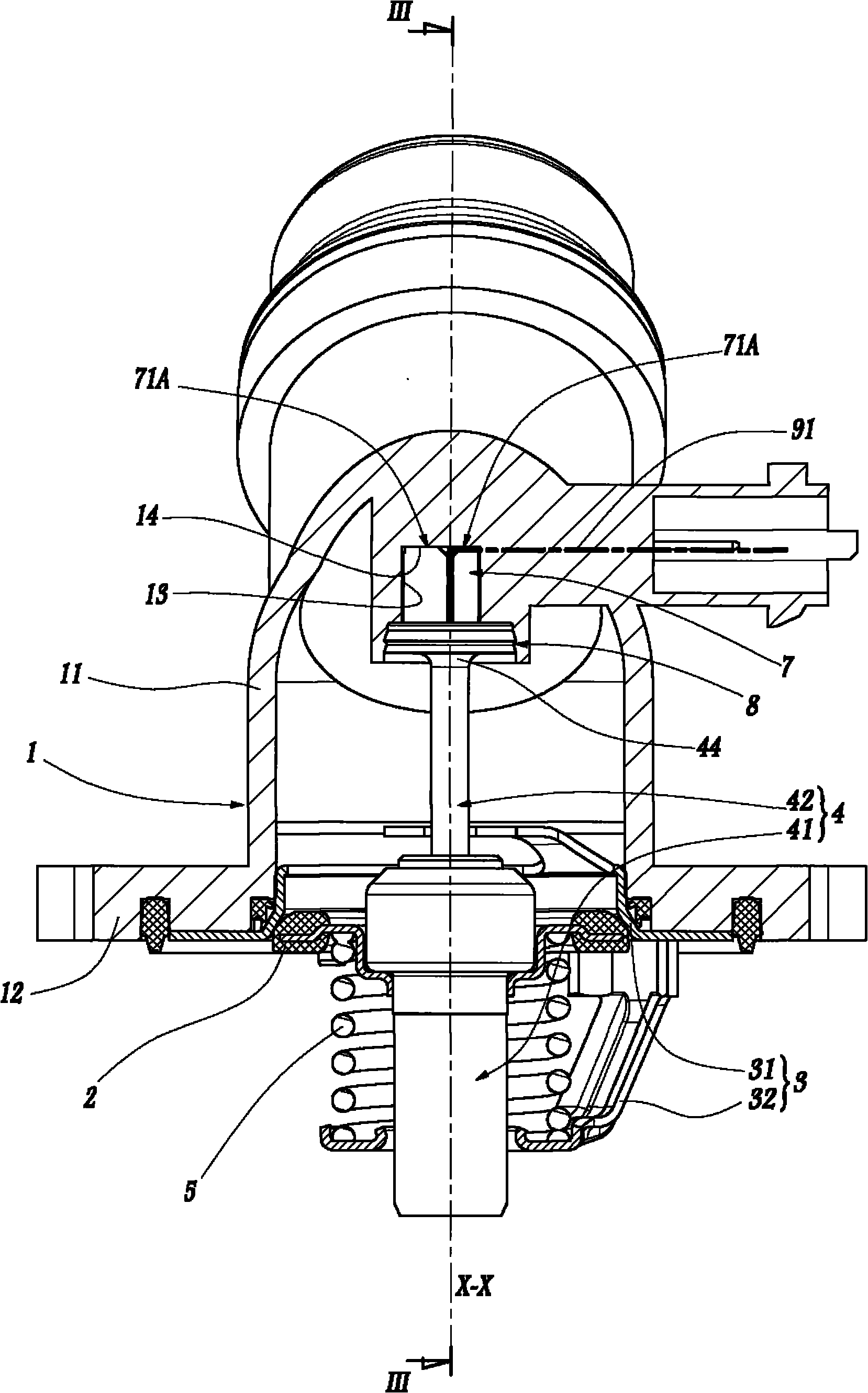

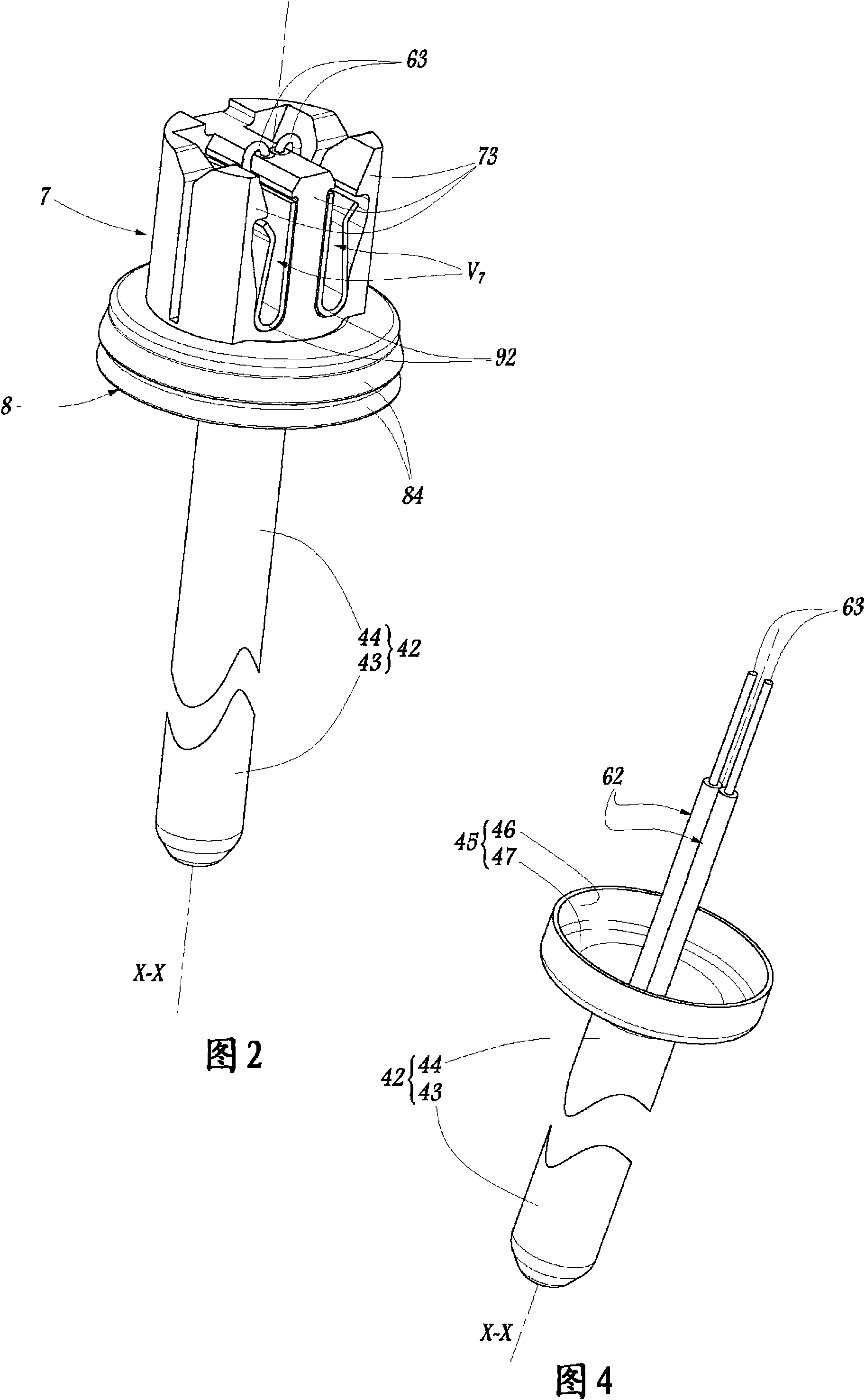

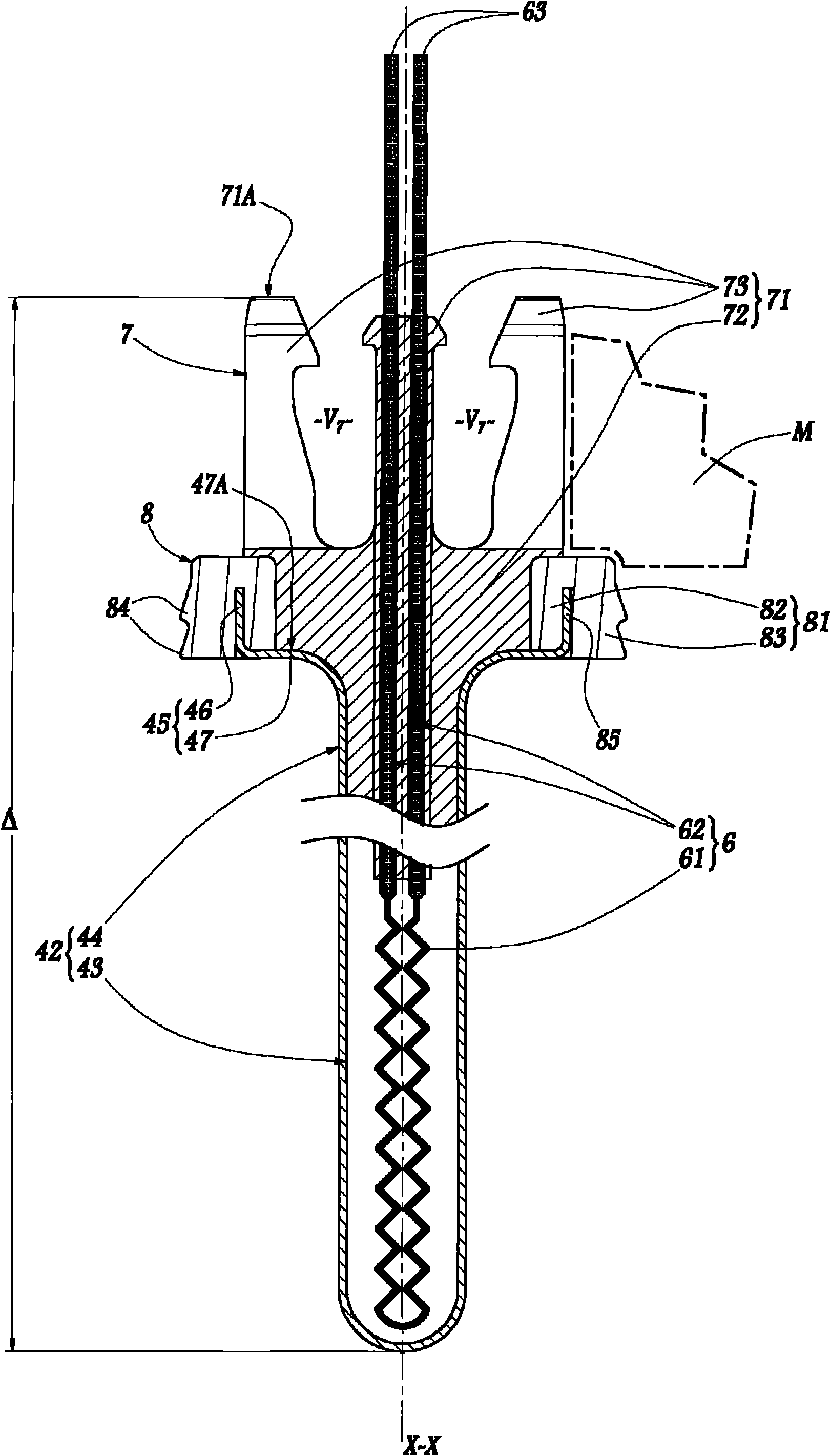

[0034] figure 1 Shown is a thermostatic valve comprising a housing 1 designed to circulate in it a fluid regulated by the other parts of the valve, in particular a cooling liquid when the valve belongs to a cooling circuit for a heat engine . The housing 1 comprises a tubular body 11 here of curved overall shape, part of which belongs to figure 1 The cutting plane is centered on the axis X-X and extends in length. During use, the aforementioned fluid flows through the body 11 between the two longitudinal ends while being regulated by the spacer plug 2, here at the end of the part of the body 11 centered on the axis X-X, the spacer plug 2 is centered on the axis X-X and can translate along this axis: if figure 1 As shown, when the plug is pushed in a sealable manner against the valve seat 31 defined by the rigid bracket 3 fixedly connected to the splint 12 of the housing 1, the flow of fluid is interrupted; and when When the isolation plug 2 is separated from the valve seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com