Apparatus and method for transferring shock-sensitive glass plates in ultra clean rooms

A glass plate, sensitive technology, used in the direction of conveyors, shipping and packaging, conveyor items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

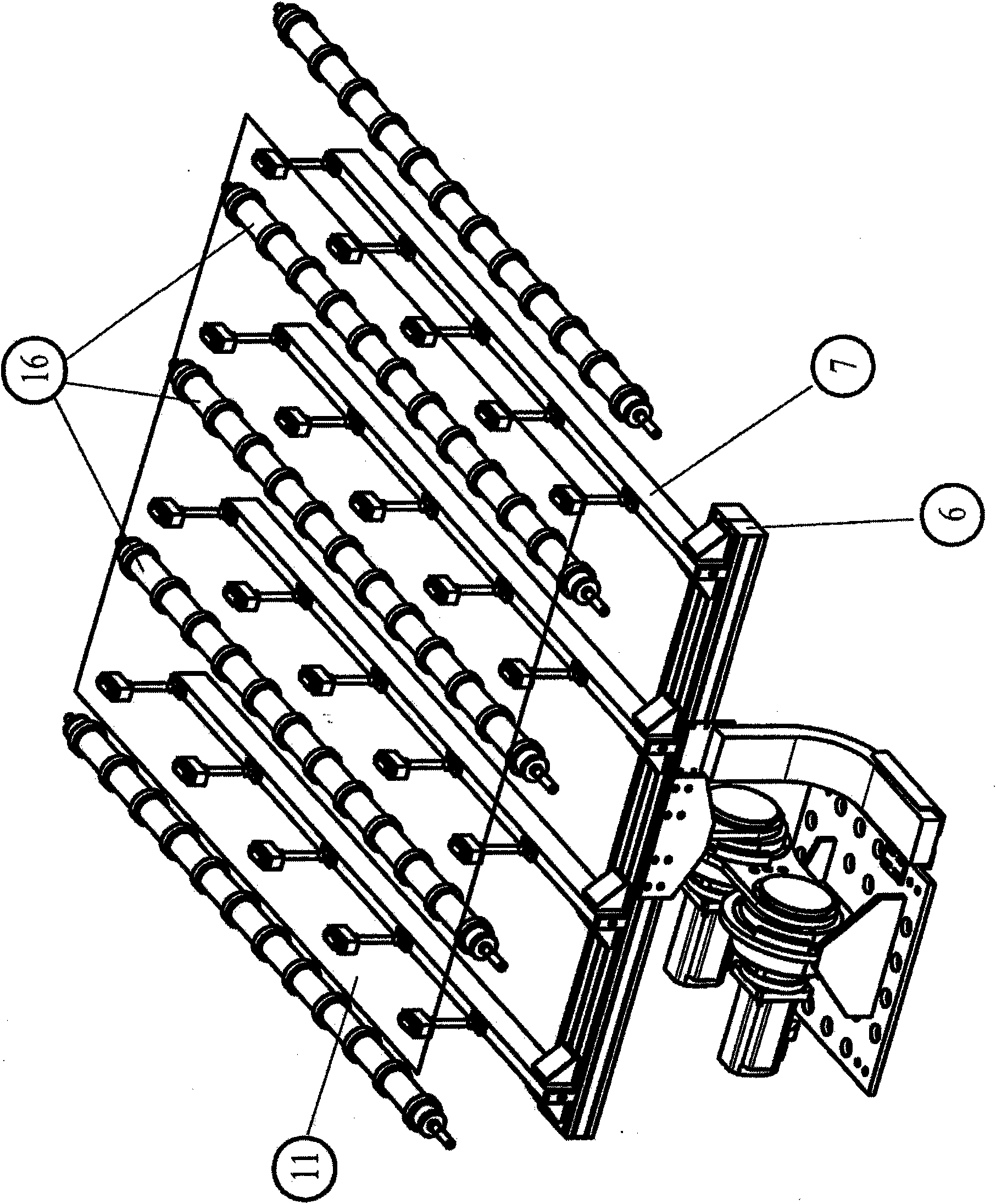

[0032] exist figure 1 In the perspective view of , it can be seen how the rollers (16) transport the glass sheet (11) to the area of the transverse support (6) of the transport fork and the suction head support (7) connected at right angles to said transverse support (6) , the glass sheet (11) is guided horizontally along said rollers (16) on the conveyor. The suction head support (7) runs substantially horizontally with the rollers (16). The precise positioning of the glass sheet (11) can be monitored using linear lasers or markers (both not shown), and its position monitored using lasers and / or sensors.

[0033] The glass plate ( 11 ) is thus positioned with the greatest possible precision for further processing under clean room conditions.

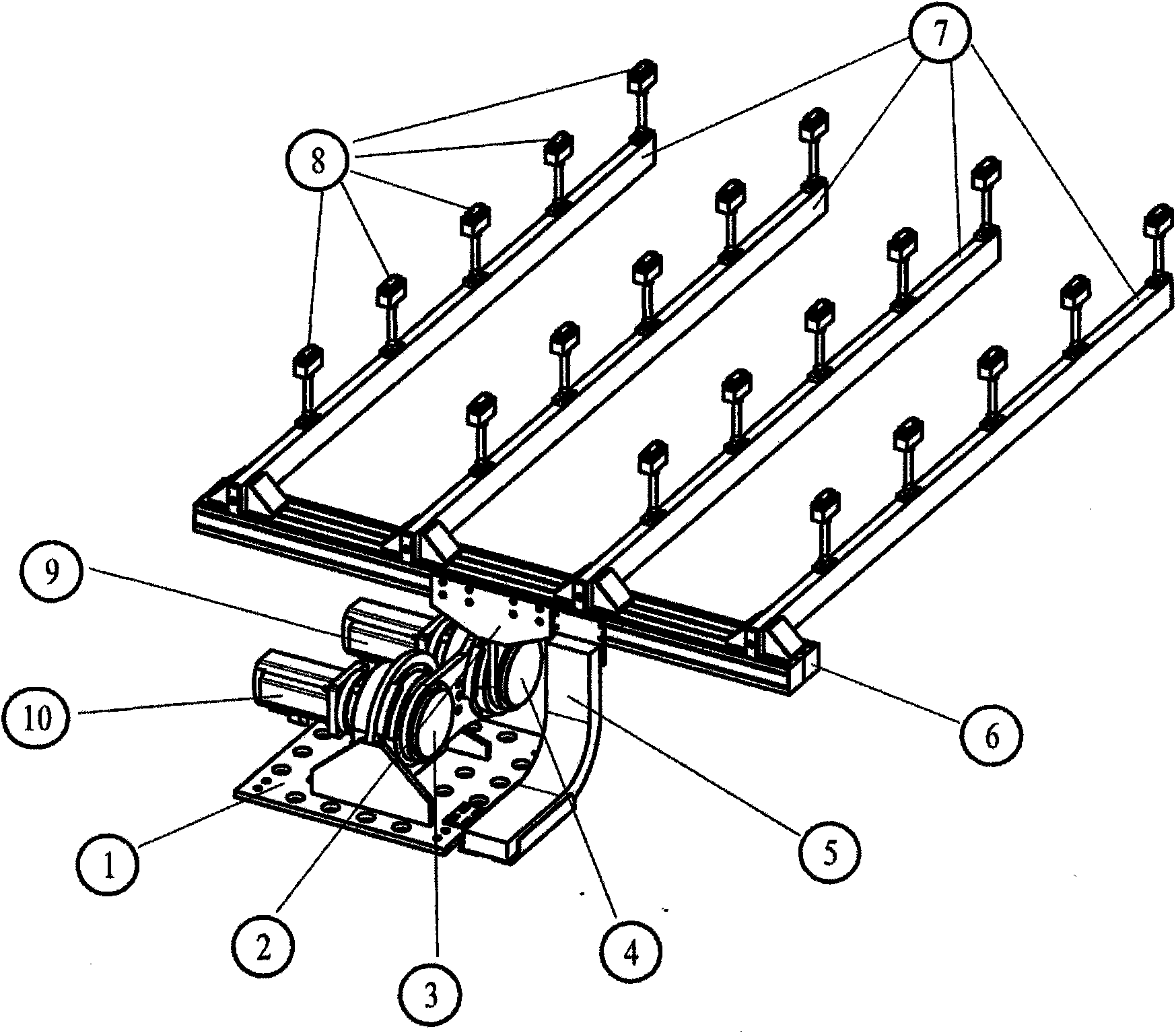

[0034] exist figure 2 In , the conveyor is shown from the same perspective, but the rollers (16) are not shown.

[0035] The delivery device is anchored to the base using the fastening plate (1). The lateral support (6) of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com