Turbomolecular pump

A technology of turbomolecular pump and pump casing, which is applied in the direction of pump, pump control, pump components, etc., can solve the problems of complex structure design of turbomolecular pump, and achieve the effect of high rotatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

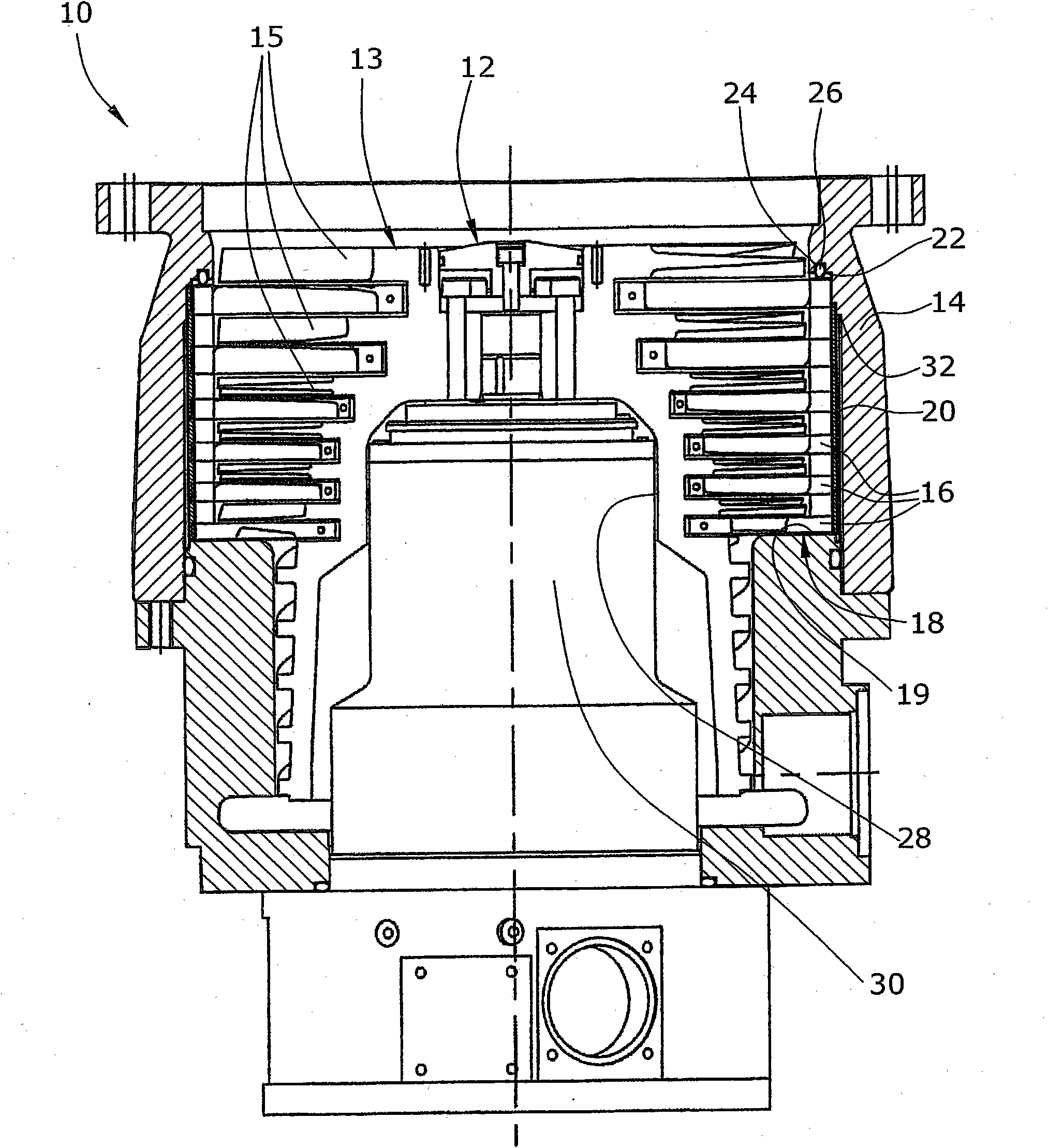

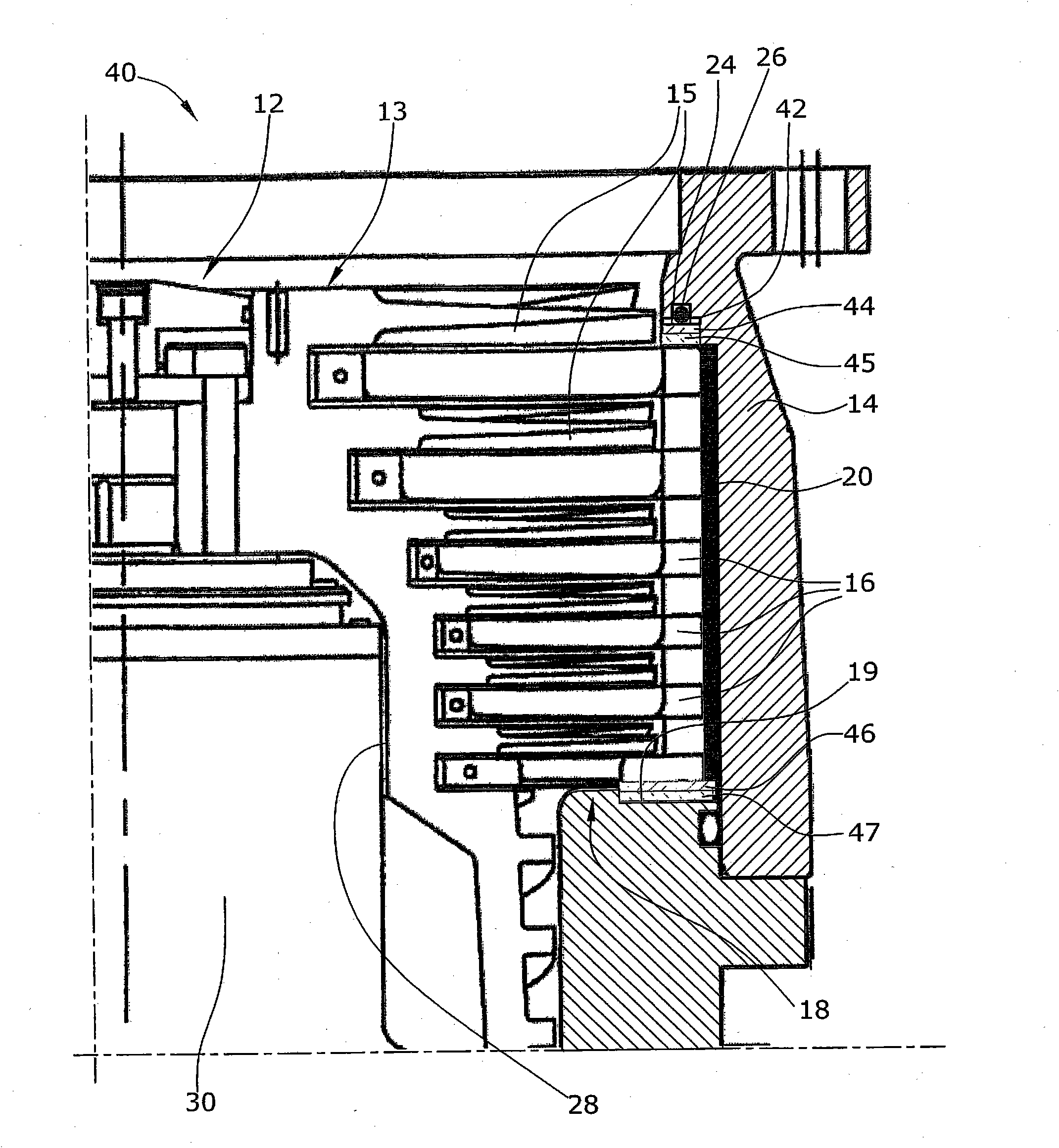

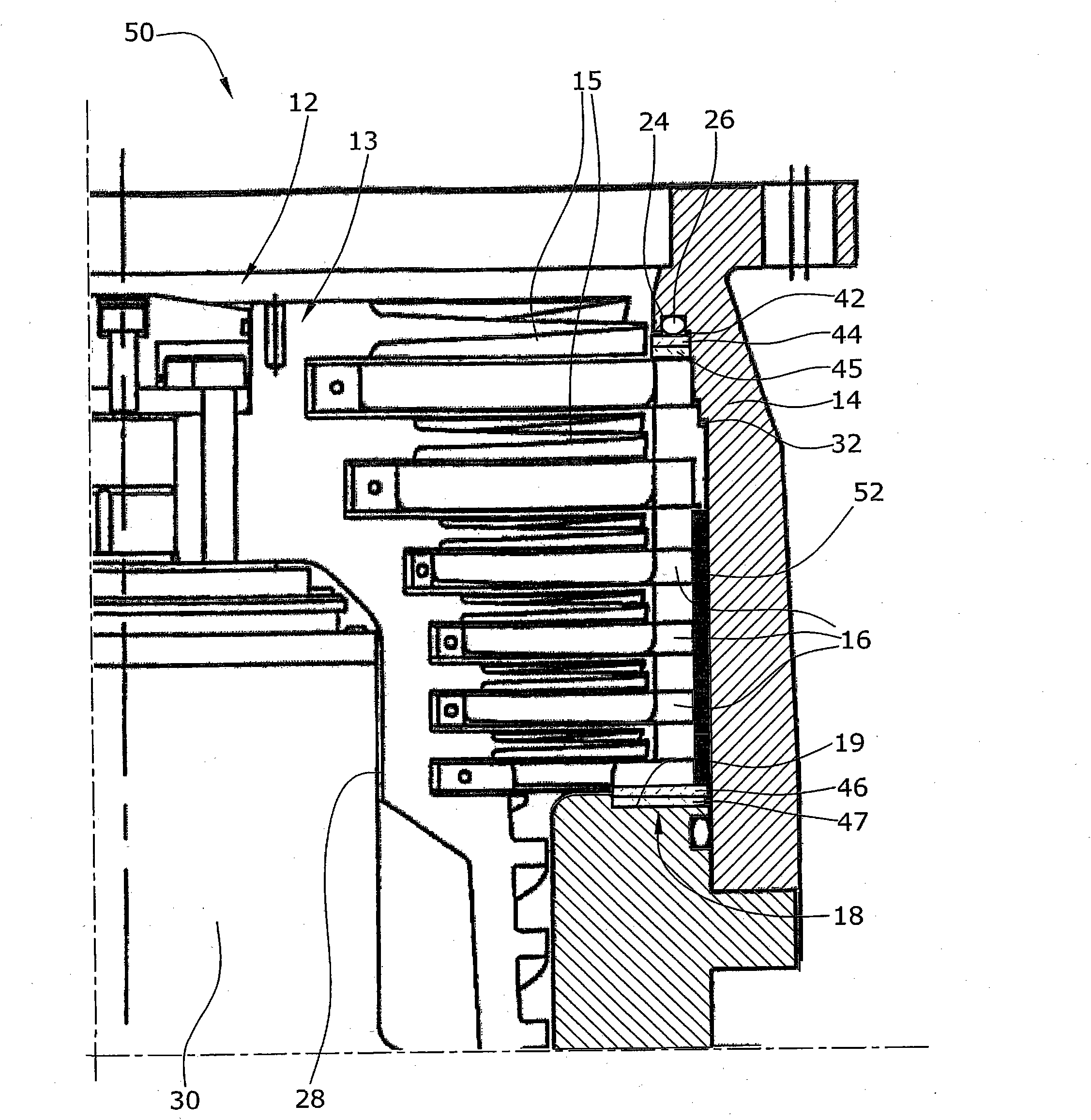

[0019] Figure 1-3 is a longitudinal sectional view of a respective turbomolecular pump 10 , 40 and 50 provided with a rotor 12 comprising a pump rotor 13 arranged to rotate on a pump housing 14 . The pump rotor 13 includes a plurality of rotor blade disks 15 . Extending into the axial gap between each pair of said blade disks is a respective one of the annular stator blade disks 16 . In this embodiment, six rotor blade disks 15 and six stator blade disks 16 are provided.

[0020] The axially assembled stator blade disks 16 together form an annular disk pack 18 . On the pressure side, the annular disk pack 18 is supported on a corresponding annular abutment surface 19 arranged in a transverse plane. The other axial end of the annular disk pack 18 is not arranged in direct axial abutment on the pump housing. Between the pump housing 14 and the annular disc pack 18 an axial gap 22 is provided such that the annular disc pack 18 is generally adapted for axial displacement with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com