Dedusting and feeding device for grain processing

A feeding device and grain technology, applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc., can solve the problems of poor dust removal effect and difficult to meet the processing requirements of high-quality grains, etc. Achieve high dust removal effect, meet high-quality grain processing requirements, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

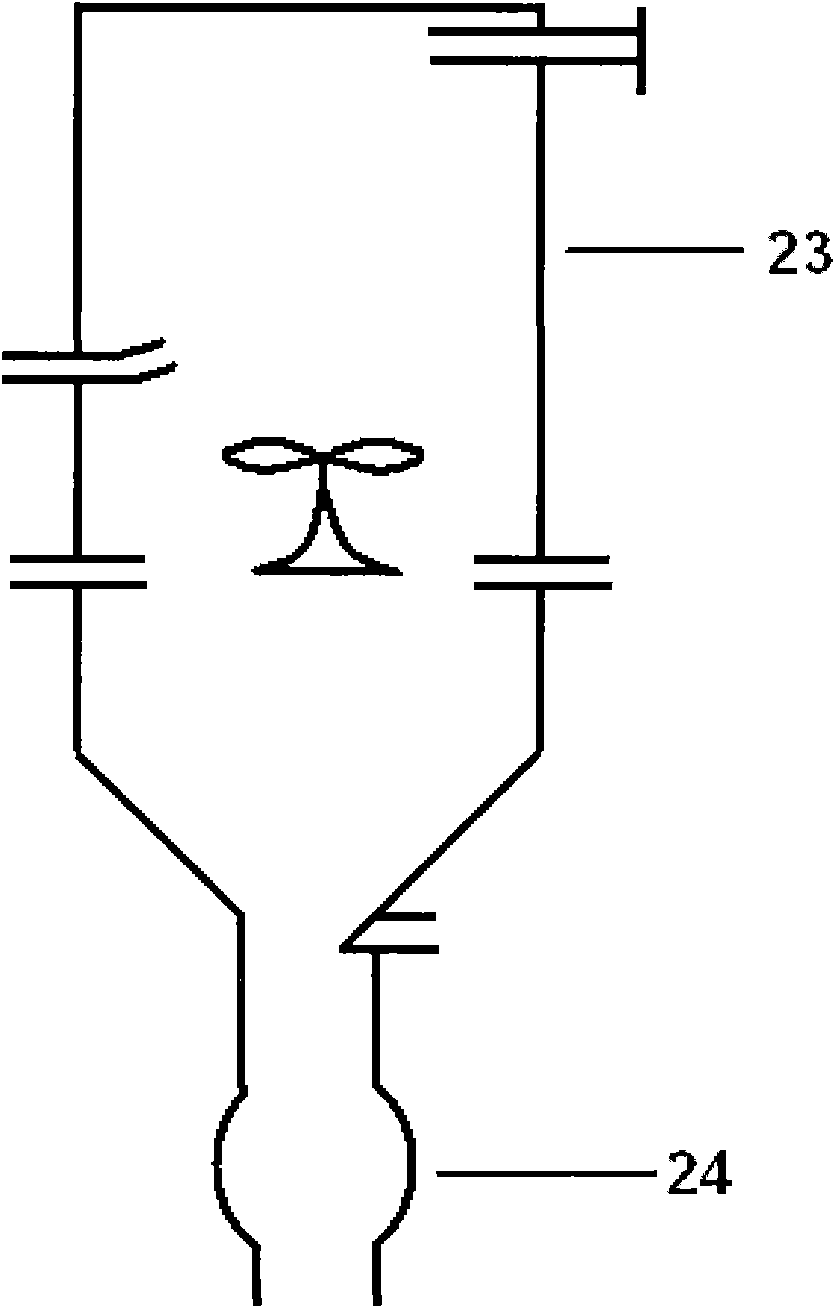

[0026] see figure 2 , a kind of dust removal feeding device in grain processing, comprises airflow dust removal part 23 and rotary valve 24, and described rotary valve 24 is arranged on the bottom end of airflow dust removal part 23, is connected with airflow dust removal part 23.

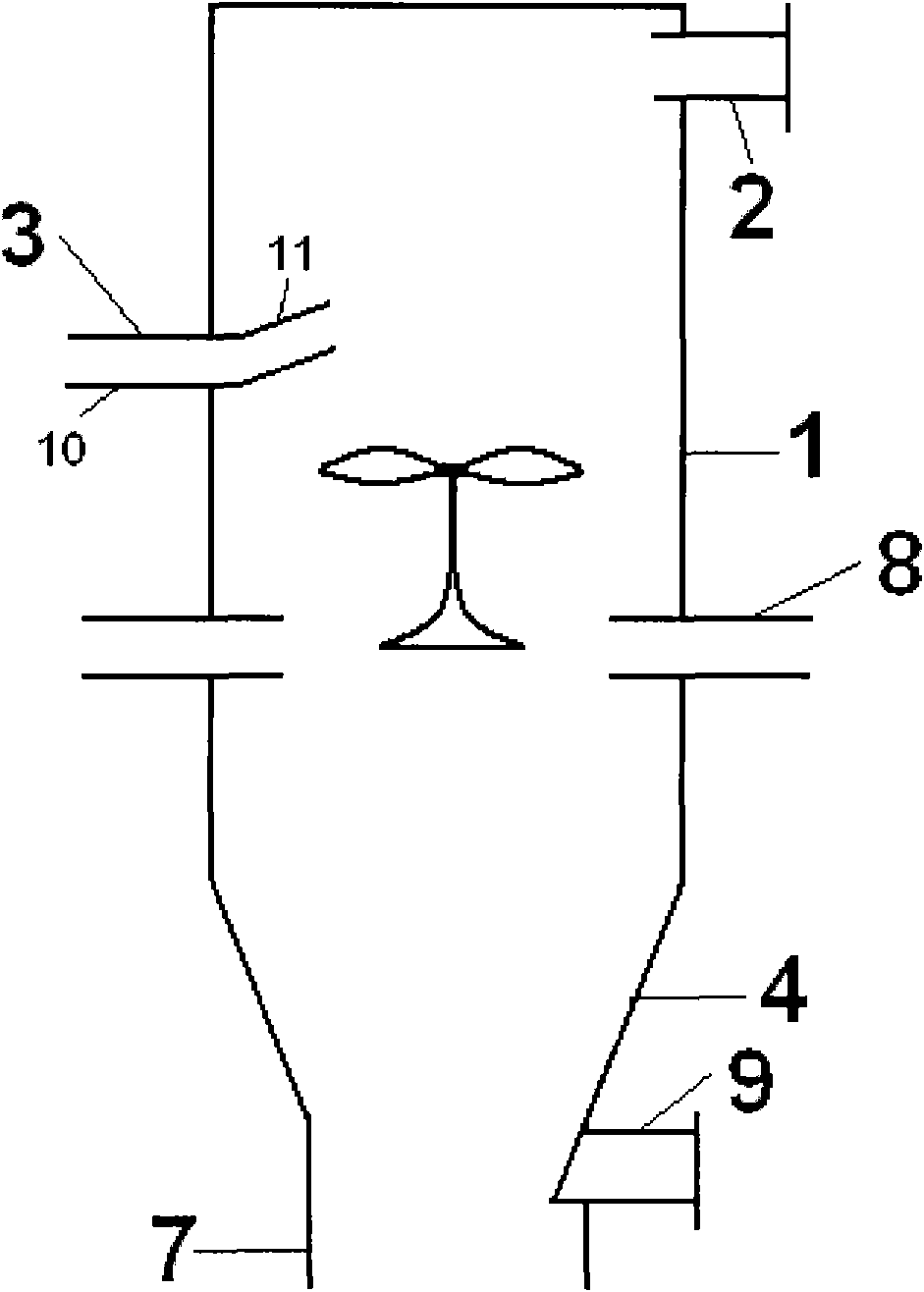

[0027] see image 3 , the airflow dedusting part 23 includes a cylindrical cavity 1, a conical cavity 4 and a cylinder 7;

[0028] The cylindrical cavity 1 is closed at the top and open at the bottom, and the conical cavity 4 is connected to the bottom of the cylindrical cavity 1;

[0029] Described conical cavity 4 is top opening, bottom end opening, and the diameter of the opening of this conical cavity 4 top is greater than the diameter of the opening of this conical cavity 4 bottoms, and the opening of this conical cavity 4 tops is connected with the opening of cylindrical cavity 1 bottom end ;

[0030] The cylinder 7 is open at the top and open at the bottom, and the opening at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com