Variable-diameter wheel leg combined wheel structure

A composite wheel and wheel leg technology, which is applied in the direction of wheels with shovel-shaped grip teeth, can solve the problems of poor obstacle-crossing ability and unsuitability of robots, and achieve the effect of fast moving speed, easy adaptability and stable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

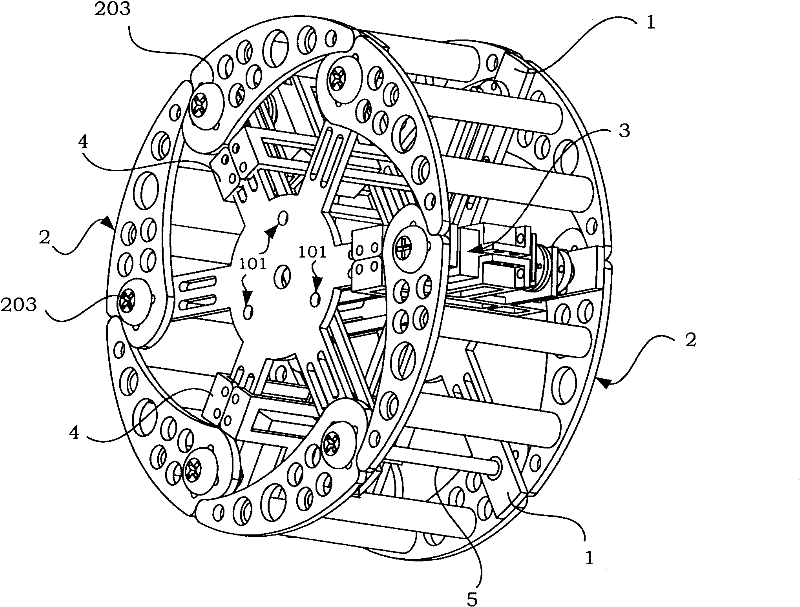

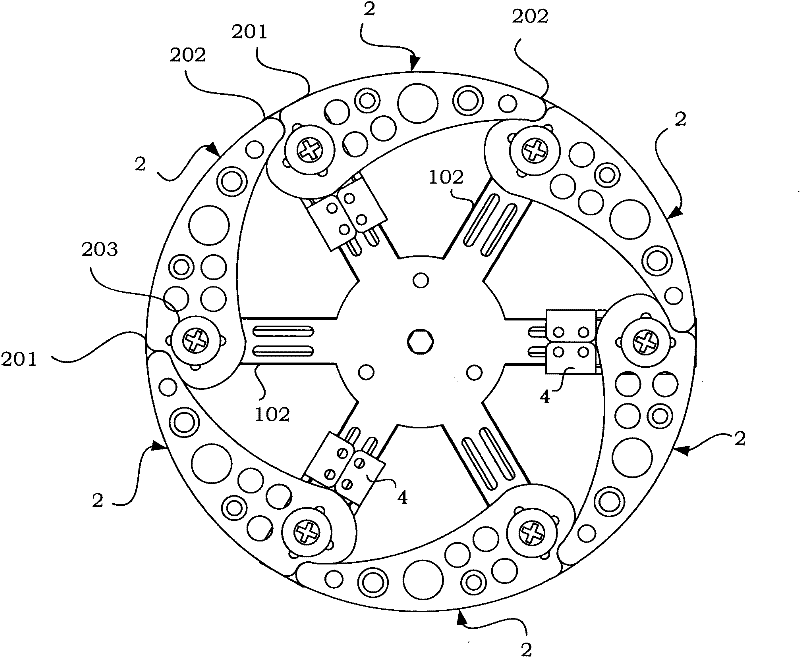

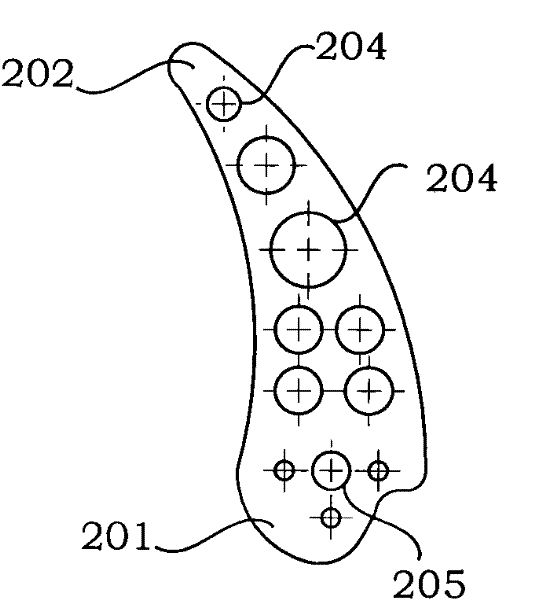

[0027] Such as figure 1 Shown is a schematic diagram of a wheel structure with a pair of coaxial hubs, each wheel structure includes a pair of hubs 1, the hubs 1 are connected by a wheel shaft, at least four spokes are arranged on the hub 1, and the end of each spoke is connected to the rim 2. The rim 2 is controlled by the driving steering gear 3 to rotate 0-120° in the plane of the hub 1, so as to realize the conversion of the wheel structure between the rim and no rim. The driving steering gear 3 is connected between the two hubs 1 through a fixed splint 4 . The following describes the specific connection relationship with the situation that each wheel hub 1 has six rims 2:

[0028] Each wheel structure has a pair of coaxial hubs 1, the two hubs 1 have the same structure, and three evenly distributed wheel shaft fixing holes 101 are respectively arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com