Powder loading machine

A technology for loading machines and powders, which is applied in the field of powder loading devices, which can solve the problems of easy generation of dust, waste of raw materials, easy pollution of the working environment, etc., and achieve the effect of avoiding waste and avoiding dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

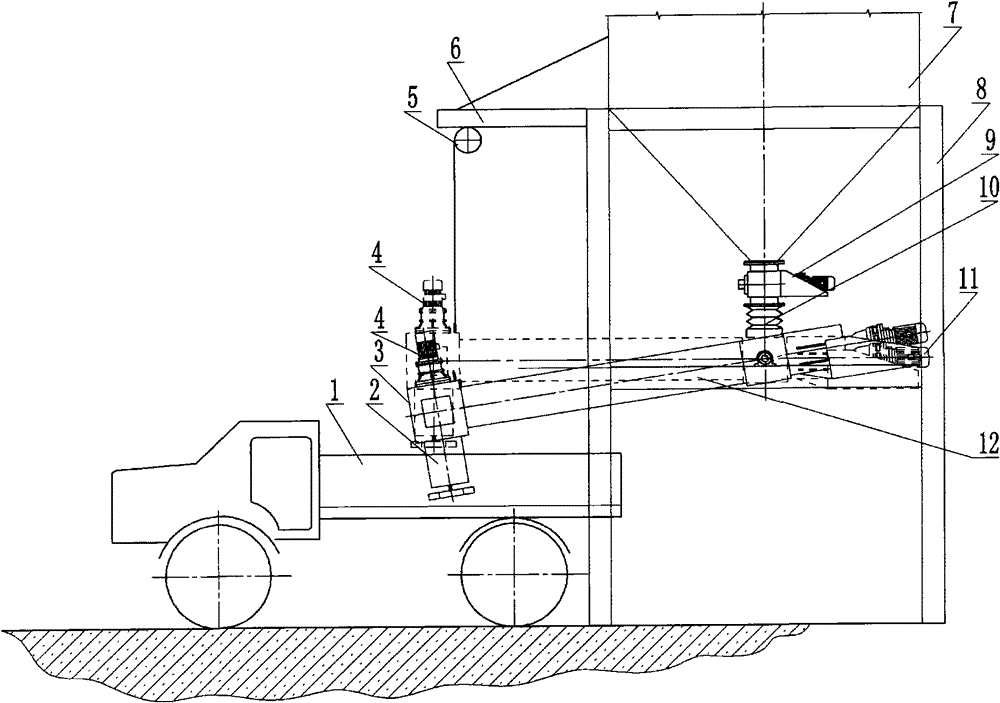

[0010] Embodiment 1, the storage bin 7 of the present invention is installed on the storage bin bracket 8, and a discharge valve 9 is installed at the outlet of the discharge funnel at the bottom of the storage bin 7, and the screw feeding cylinder 12 is hinged on the outlet of the discharge funnel. On the storage bin bracket 8 at the lower part of the valve 9, a flexible joint material pipe 10 is fitted between the feed port of the screw feed cylinder 12 and the discharge port of the discharge valve 9, so that the screw feed cylinder 12 can be moved up and down or Rotate left and right, by cross-connecting the discharge end of the screw feeding cylinder 12 with the discharge connecting cylinder 3, the movement direction of the powder is changed, so that the powder directly leads into the container; Set the electric hoist support frame 6, and hoist the connecting cylinder 3 on the electric hoist 5, so that the screw feeding cylinder 12 faces the container position that needs to...

Embodiment 2

[0011] Embodiment 2, the present invention can also be fitted with a screw unloading device in the connecting cylinder 3 and the discharge cylinder 2, and a longitudinal screw driving device 4 is installed on the top of the connecting cylinder 3, and the longitudinal screw driving device 4 is connected with the matching sleeve. The barrel 3 and the screw unloading device in the discharge barrel 2 are matched and connected, so that the powder is transported into the container through the screw unloading device, so that the powder no longer falls freely, further reducing the possibility of generating dust. refer to figure 1 , all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com