Integrated treatment device for high-concentration sewage

A sewage treatment device and technology for sewage treatment, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of small footprint, convenient management, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

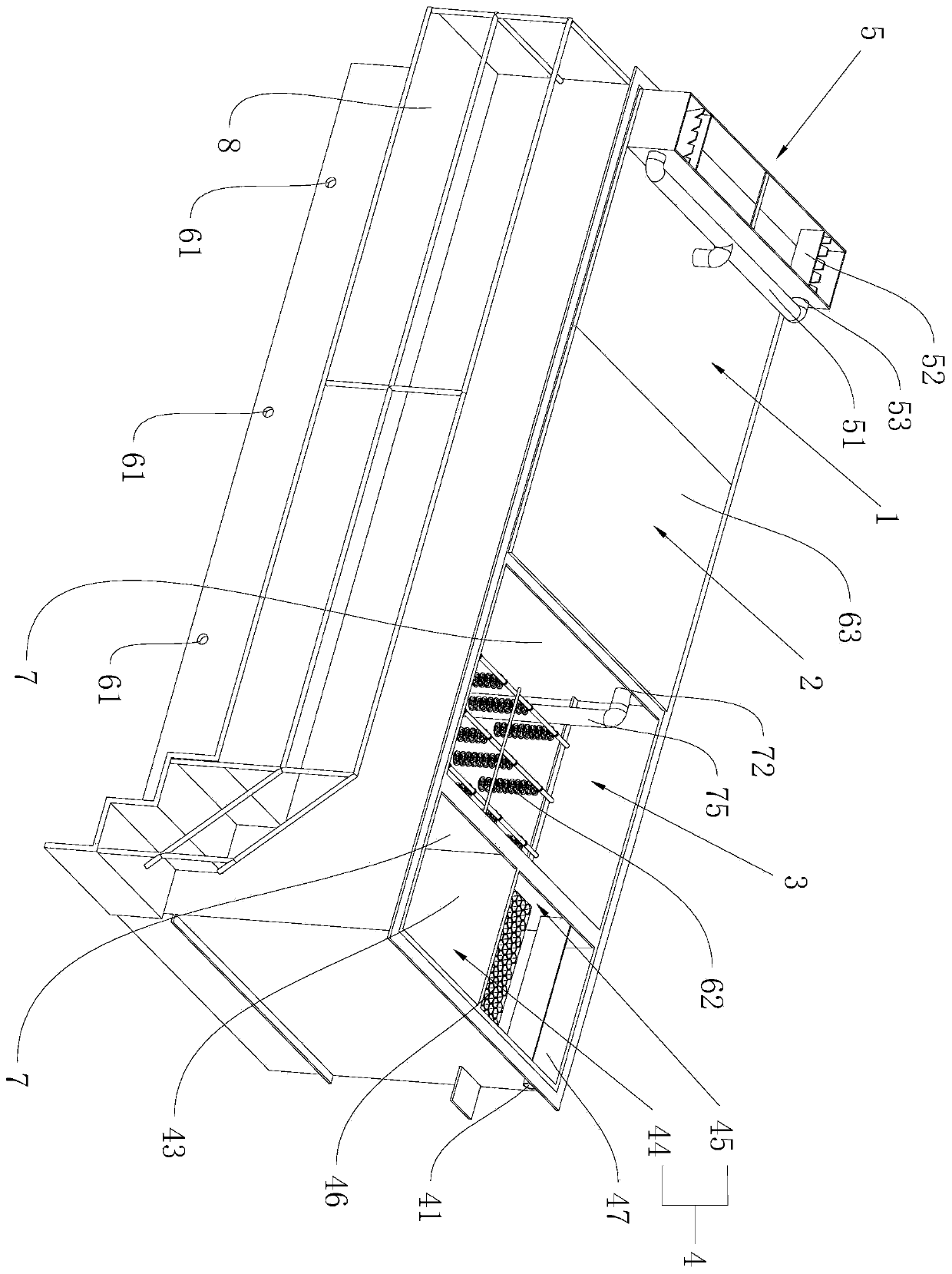

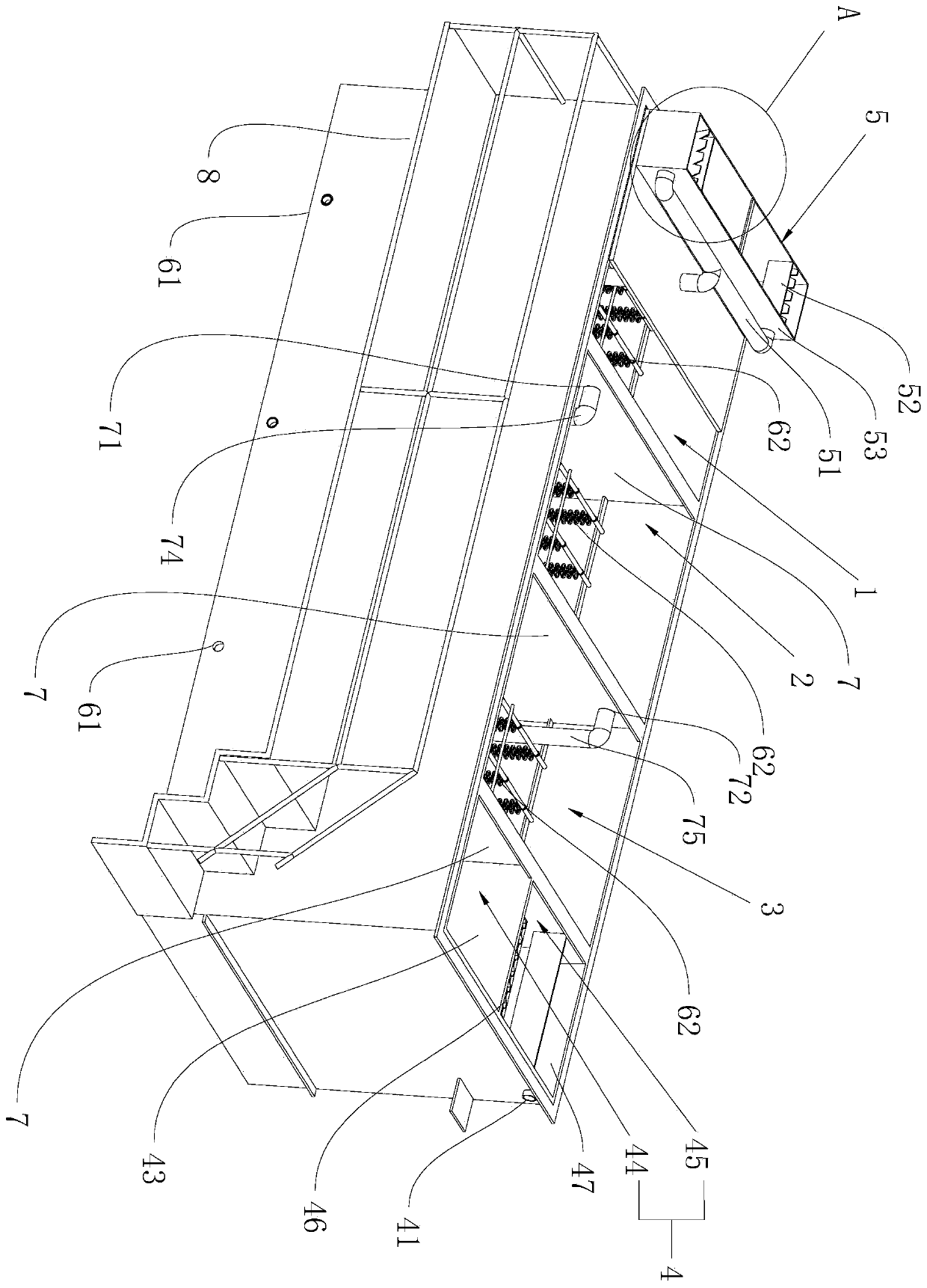

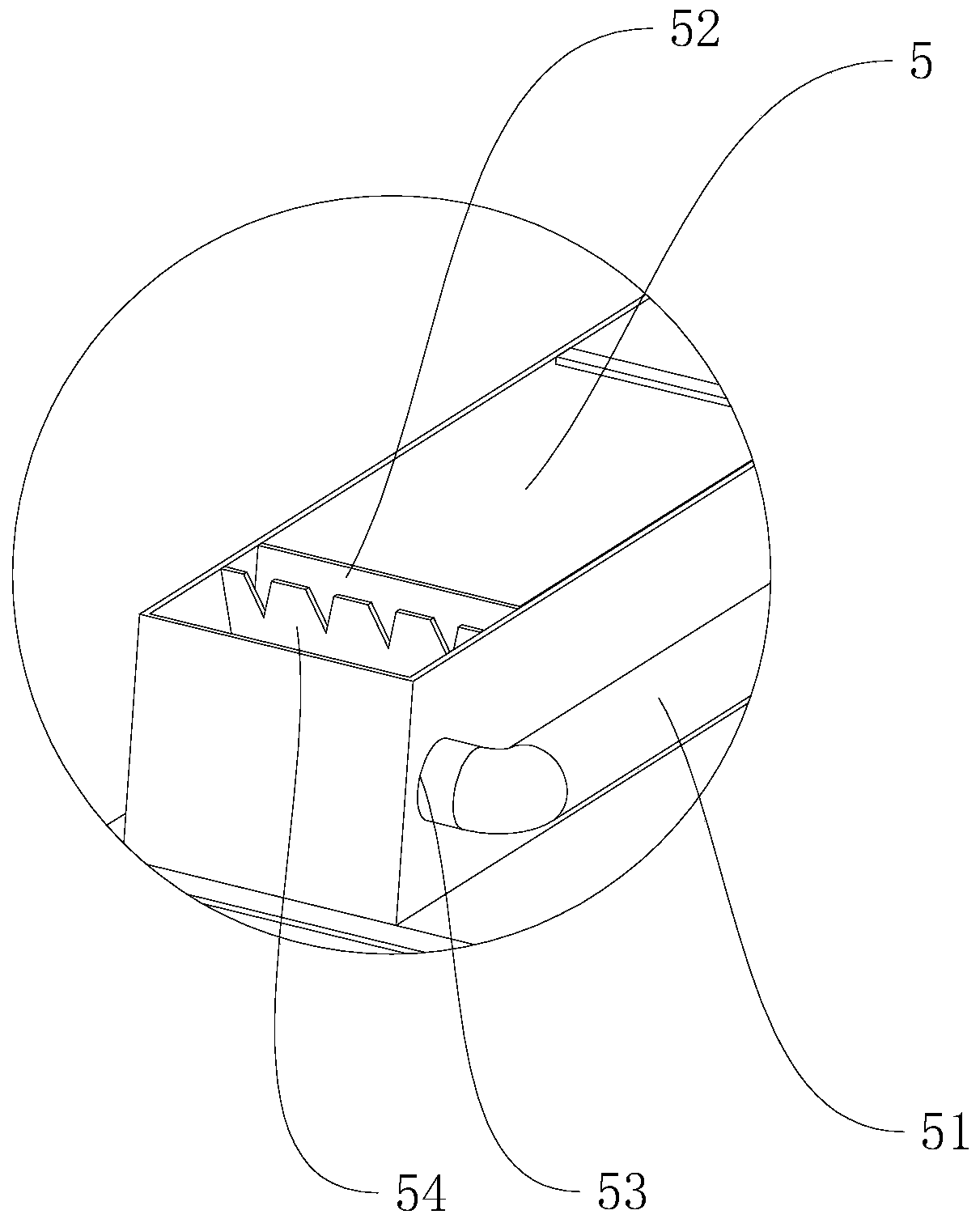

[0039] refer to figure 1 , is a high-concentration integrated sewage treatment device disclosed by the present invention, comprising a sewage treatment tank with an opening and a walking platform 8 located on the side wall of the sewage treatment tank. The welded barrier plate 7, the sewage treatment tank is divided into the separation tank 1, the anaerobic tank 2, the oxidation tank 3 and the filter tank 4 connected in sequence through the barrier plate 7; the barrier plate 7 in the separation tank 1 and the anaerobic tank 2 is shown in the figure Not shown; the bottom of the sewage treatment tank is provided with four sludge discharge outlets 61 respectively connected to the separation tank 1, anaerobic tank 2, oxidation tank 3 and filter tank 4, and the sludge discharge outlet 61 at the bottom of the filter tank 4 is not shown, A sludge pump for controlling its extraction is provided at the sludge outlet 61, which is not shown in the figure; an outlet pipe 41 is connected t...

Embodiment 2

[0052] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, a horizontal support plate 11 protrudes from the end of the separation tank 1 facing away from the anaerobic tank 2, and the water inlet tank 5 is placed on the support plate 11. , the support plate 11 below is placed with some control boxes 12 for controlling the work of different sewage pumps in the sewage treatment tank, which is convenient for the staff to place the control boxes 12, and the later maintenance and operation are more convenient.

Embodiment 3

[0054] combine figure 2 and Figure 6 It can be seen that the difference between the third embodiment and the first embodiment is that a low-pressure connecting pipe 31 is provided at the oxidation water conduit 75 and the second through hole 72, and the diameter of the low-pressure connecting pipe 31 gradually increases from the center to both ends. A one-way valve 311 is installed at the smallest diameter of 31; when the sewage in the anaerobic tank 2 passes through the low-pressure connecting pipe 31, a low-pressure area is generated in the low-pressure connecting pipe 31 due to the reduction of the diameter of the low-pressure connecting pipe 31, so that the one-way The outside air at the valve 311 is sucked into the low-pressure connecting pipe 31, and when the sewage passes through a section where the diameter of the low-pressure connecting pipe 31 gradually increases, the air pressure at this place gradually increases, and the air entering the one-way valve 311 is unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com