Shell-tube heat exchanger

A technology of shell-and-tube heat exchangers and heat exchange tube bundles, which is applied in the direction of heat exchanger types, indirect heat exchangers, lighting and heating equipment, etc. area, the effect of increasing the effective convective heat transfer area and improving the convective heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Carry out further detailed description below in conjunction with accompanying drawing:

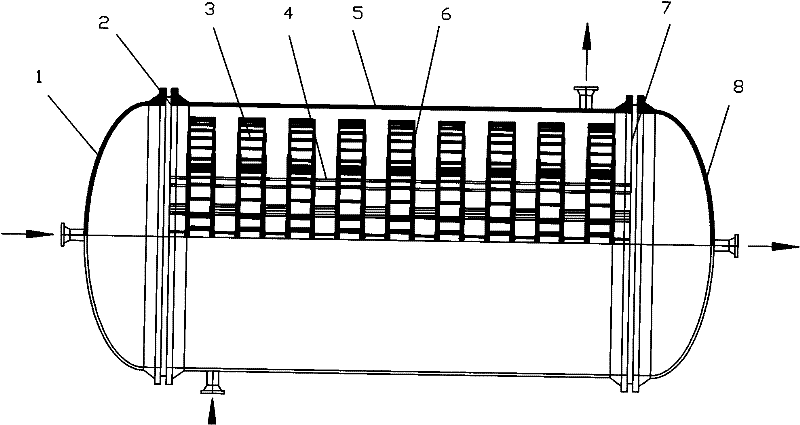

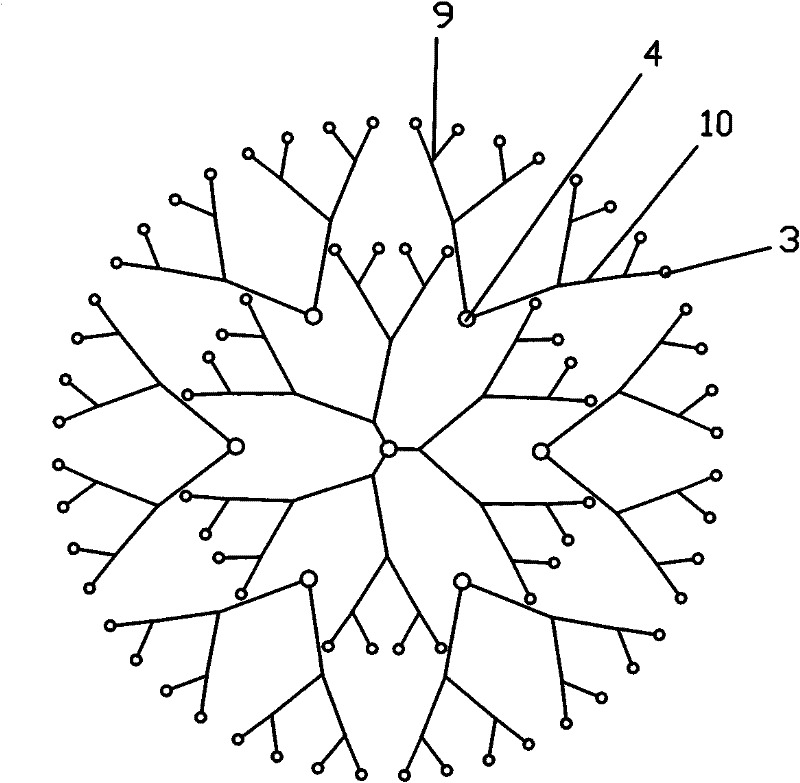

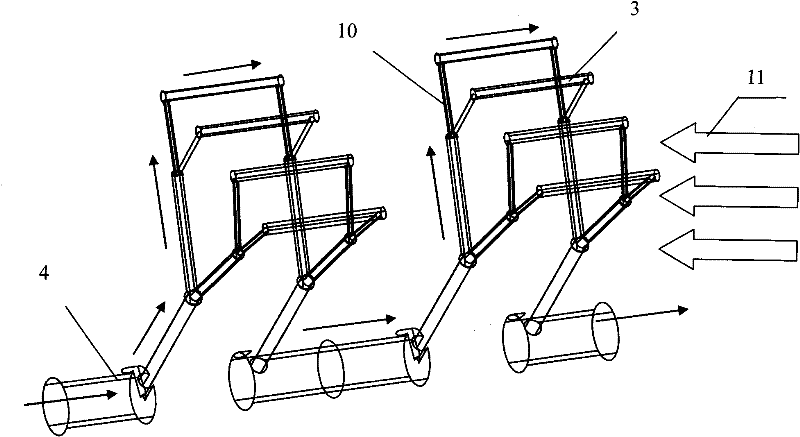

[0026] figure 1A structural schematic diagram of the present invention is given, a shell-and-tube heat exchanger with a tree-shaped characteristic heat exchange tube bundle, which is composed of a tree-shaped heat exchange tube bundle, a shell, and a tube sheet. The specific structure includes: left head 1, left tube plate 2, branch connecting pipe 3, main connecting pipe 4, bifurcated connecting pipe 10, shell 5, tree-shaped heat exchange tube bundle 6, right tube plate 7 and right seal The first 8 and other main parts. The tube plates 2 and 7 are arranged at both ends of the shell, and the tree-shaped heat exchange tube bundles 6 are arranged in layers along the axial direction of the shell, and the main communication pipes 3 located on both sides of the tree-shaped heat exchange tube bundles are at both ends of the shell Pass through the tube sheets 2, 7 and be welded or expand...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap