Cylindrical core for manufacturing endless belt-shaped body, and method for manufacturing endless belt-shaped body

A technology of cylindrical core and strip body, applied in the field of cylindrical core body, can solve the problems of reducing the temperature of the heating cylindrical core body, reducing time and cost, unevenness, etc. The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

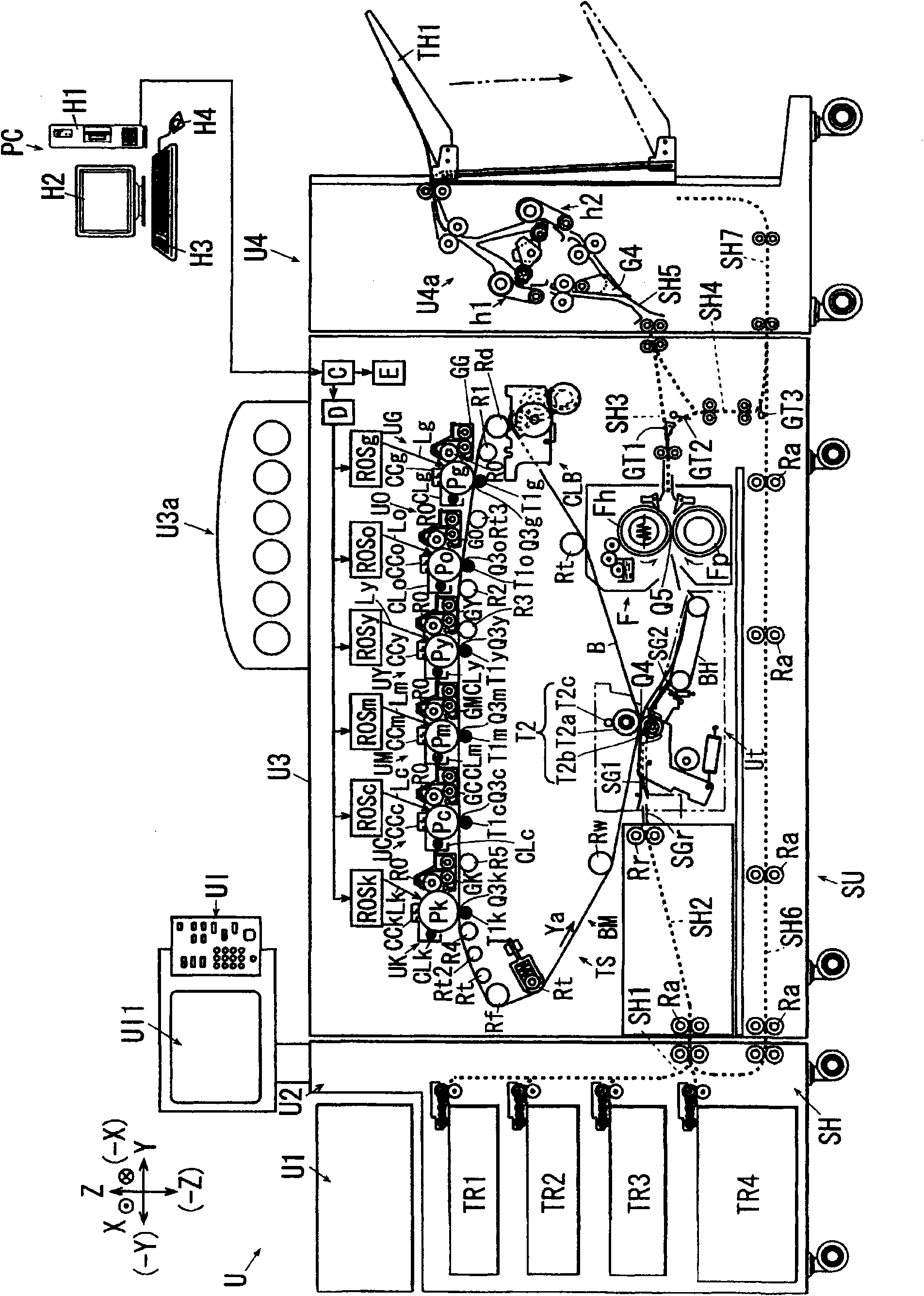

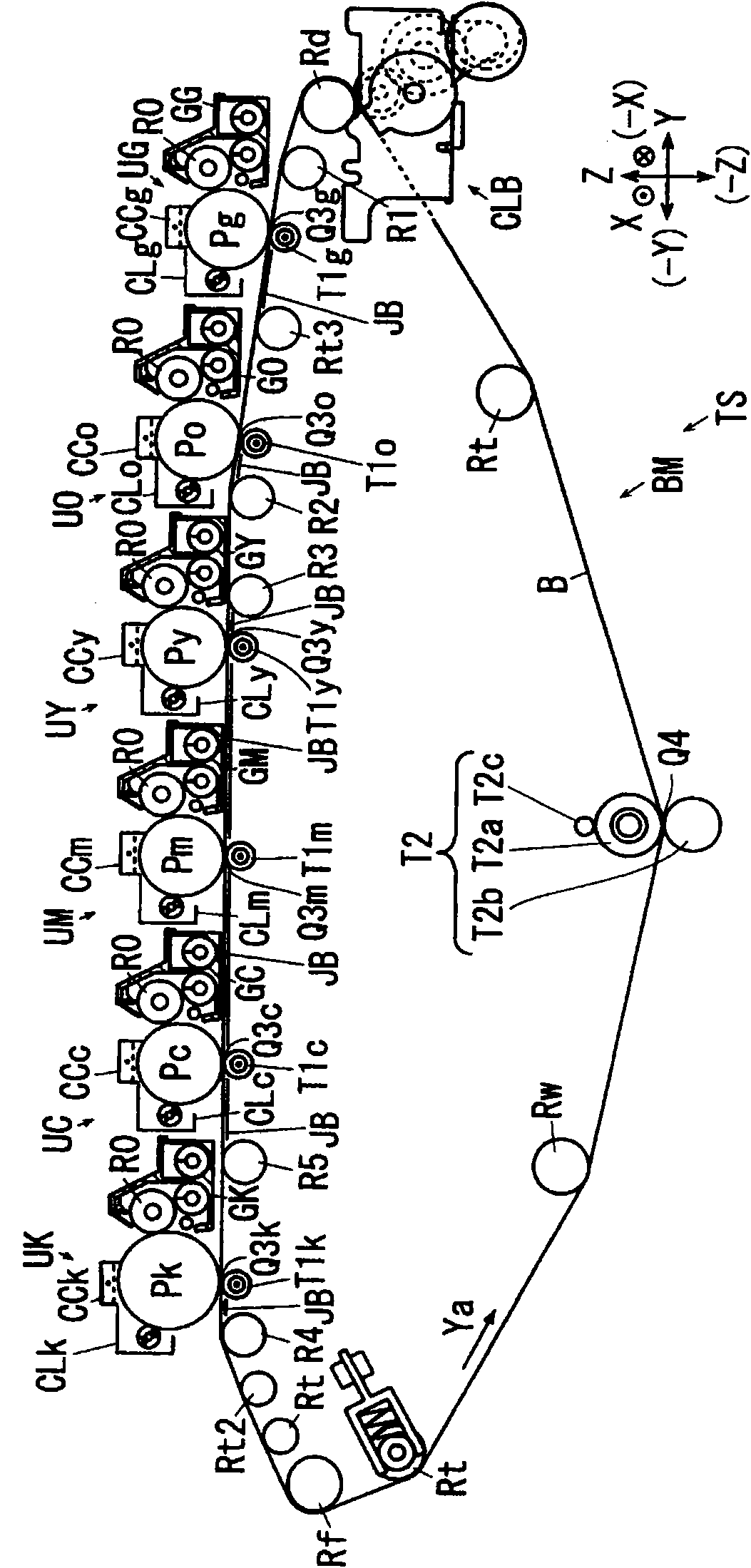

[0036] figure 1 is an explanatory diagram showing the entire image forming apparatus according to Embodiment 1 of the present invention.

[0037] Such as figure 1 As shown, the image forming apparatus U according to Embodiment 1 includes: a user interface UI serving as an example of an apparatus operating portion; an image input device U1 serving as an example of an image information input device; a paper feeding device U2; an image forming device the main body U3; and the sheet handling unit U4.

[0038]The user interface UI is provided with: a copy start key, which is used as an example of an operation start button; a copy quantity setting key, which is used as an example of a key for setting the copy quantity; input buttons such as numeric keys, which are used as numeric input buttons instance of ; and display device UI1.

[0039] The image input device U1 includes an image scanner serving as an example of an image reading device. Such as figure 1 As shown, in the imag...

experiment example 1

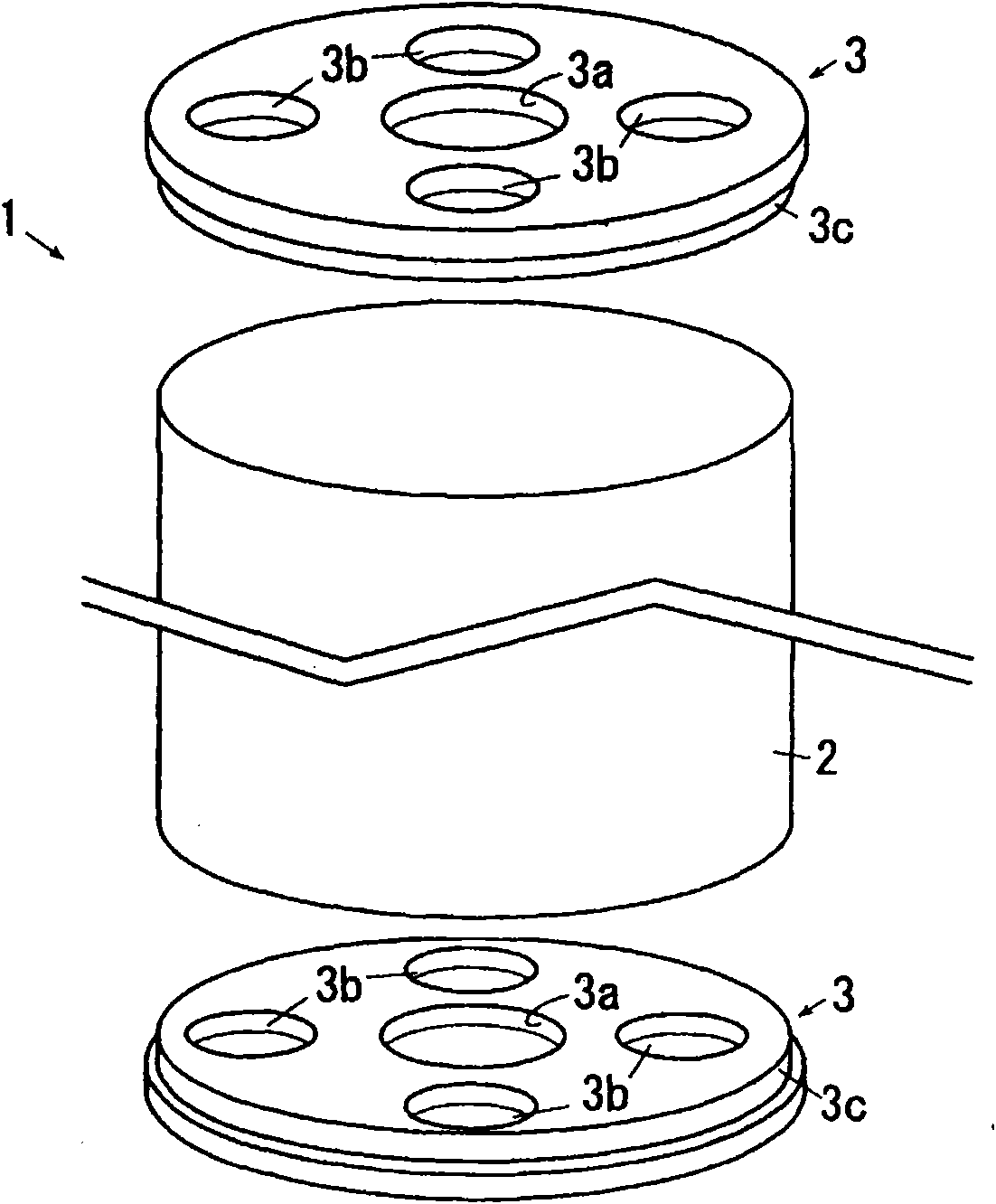

[0120] In Experimental Example 1, a cylindrical body made of SUS 304 stainless steel and having an outer diameter of 600 mm, a thickness of 1.2 mm, and a length of 900 mm was prepared as the cylindrical portion 2 . The cylinder is obtained by crimping and welding a plate having a thickness of 1.2 mm. Sand the seams well to eliminate tendons and steps. The cylindrical portion has a sufficiently small thickness relative to the outer diameter. Thus, the cylindrical portion 2 is deformed by its own weight, and cannot maintain the cylindrical shape without being supported. The surface of the cylindrical portion 2 was roughened by blasting the surface of the cylindrical portion 2 with spherical aluminum particles so that the roughness Ra was 0.4 μm.

[0121] A silicon-based release agent (manufactured by Shin-Etsu Chemical Co., Ltd., trade name: SEPA-COAT (registered trademark)) was applied on the surface of the cylindrical portion 2 by spraying. Then, the cylindrical portion 2 w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com