Nickel-hydrogen battery discharging at low temperature and high multiplying power and preparation method and negative plate thereof

A technology for high-rate discharge and nickel-metal hydride batteries, which is applied in the manufacture of nickel batteries, alkaline battery electrodes, and alkaline batteries, and can solve problems such as limited electron conductivity on the surface of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

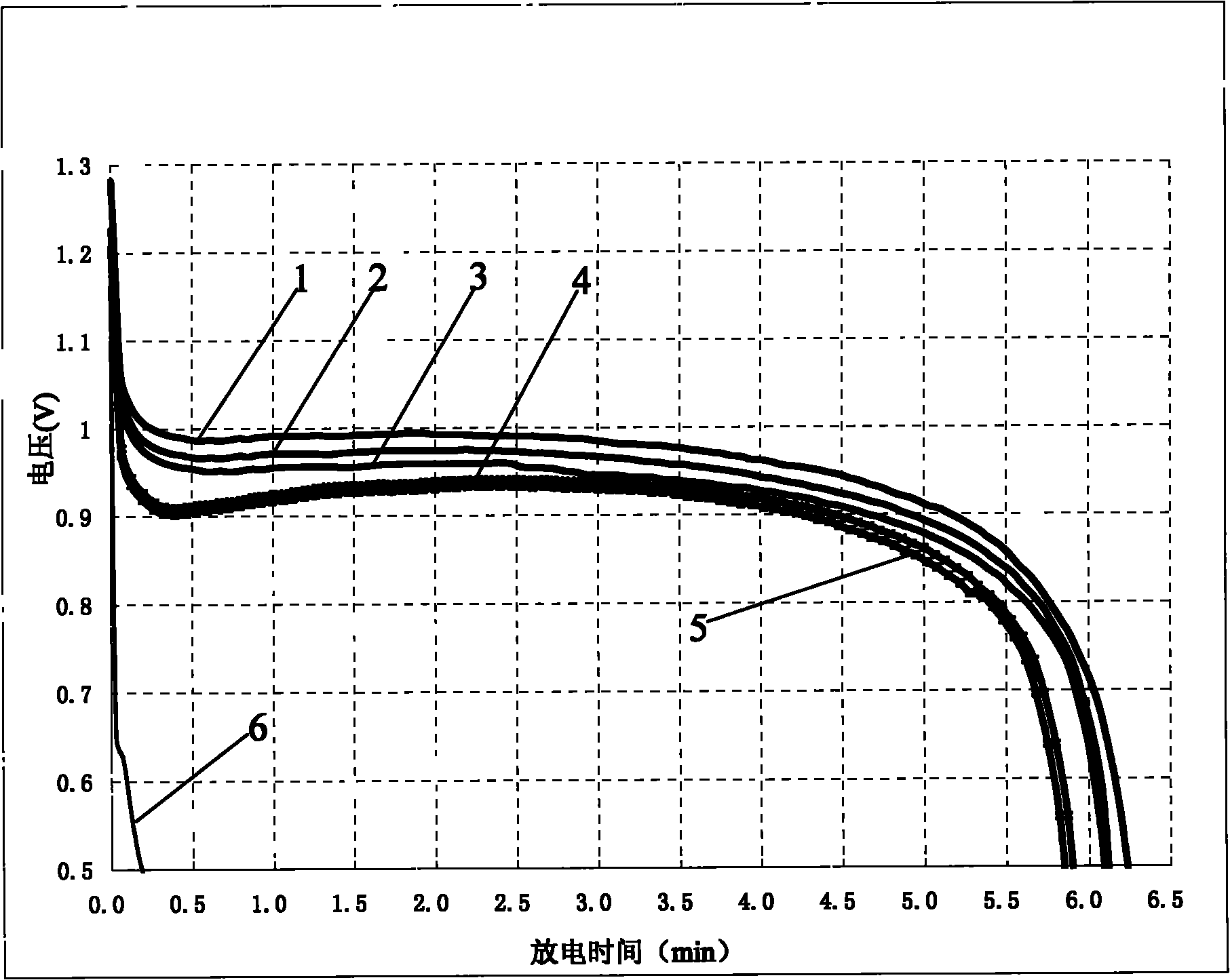

Image

Examples

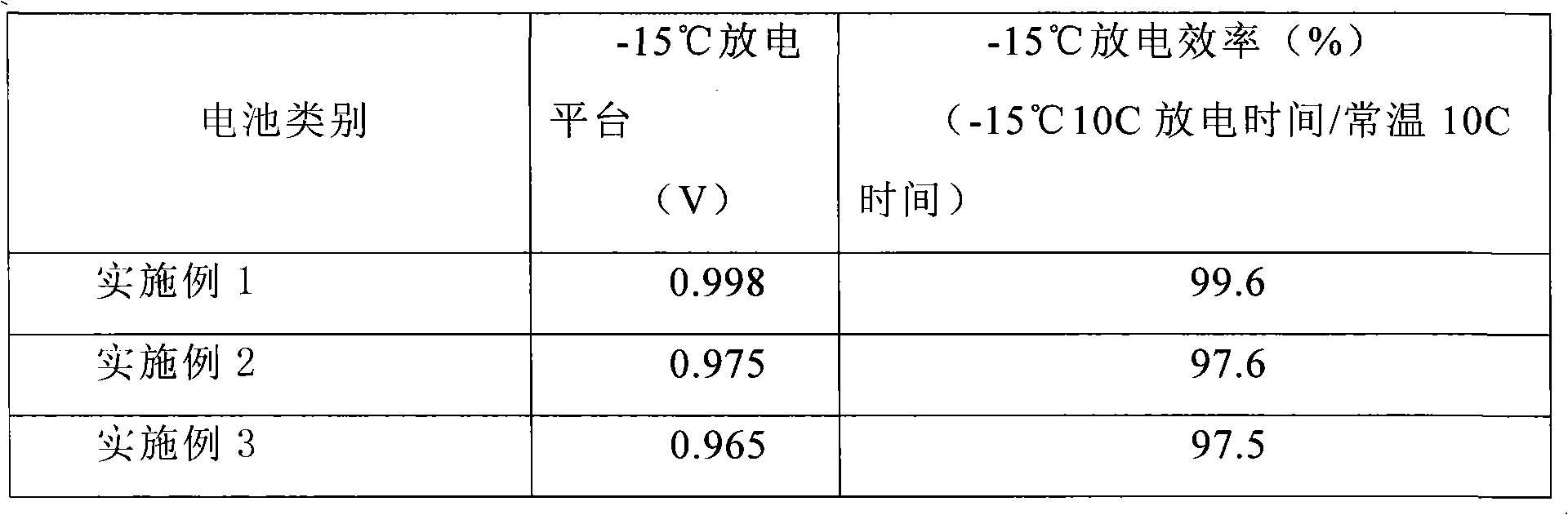

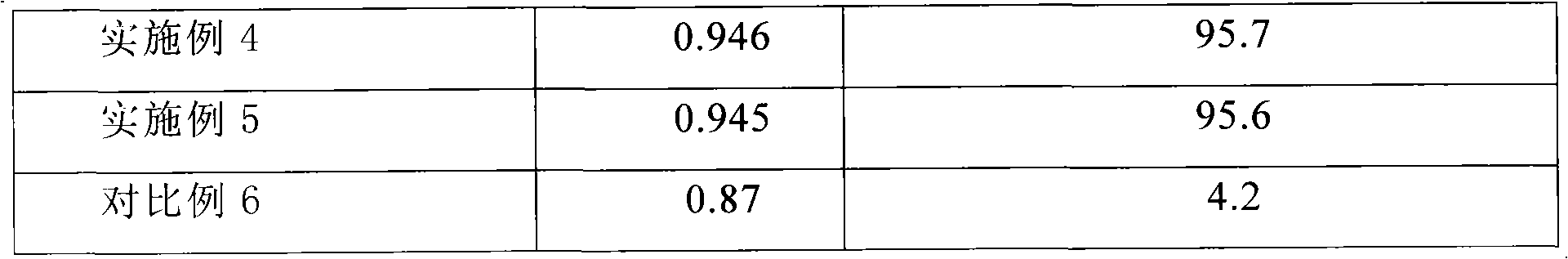

Embodiment 1

[0016] A nickel-metal hydride battery, the negative plate uses the AB5 hydrogen storage alloy powder produced by Zhuhai Jinfenghang Power Technology Co., Ltd., and the product model is 6S. The surface of the hydrogen storage alloy powder is first plated with nickel by electroless nickel plating, the plating solution is nickel sulfate, the oxidizing agent is sodium hypophosphite, and the temperature of the plating solution is 85°C. Put the hydrogen storage alloy powder in the plating solution, perform electroless plating for 10 minutes, filter, wash with water, and vacuum dry to prepare the hydrogen storage alloy powder with a nickel content of 90-100% in the surface layer of 0.5-3 μm. The treated hydrogen storage alloy powder is used, the negative electrode conductive skeleton is made of nickel mesh, and the negative electrode sheet is made by dry powder coating. The nickel content within 0.5-3 μm of the negative electrode surface layer is 80-95%. The positive plate uses spher...

Embodiment 2

[0018] A nickel-metal hydride battery, the negative plate uses the AB5 hydrogen storage alloy powder produced by Zhuhai Jinfenghang Power Technology Co., Ltd., and the product model is 6S. The conductive skeleton of the negative electrode is made of nickel mesh, and the negative plate is made by dry powder coating. The electroless nickel plating method is used. The plating solution is nickel sulfate, the oxidizing agent is sodium hypophosphite, and the temperature of the plating solution is 85°C. Put the negative electrode sheet in the plating solution, perform electroless plating for 10 minutes, filter, wash with water, and dry in vacuum to prepare the negative electrode sheet with a nickel content of 85-100% in the surface layer of 0.5-3 μm. The positive plate uses spherical nickel hydroxide produced by Henan Xinfei Kelong Power Supply Co., Ltd., and cobaltous oxide produced by Loudihong Sun Power New Material Co., Ltd. The positive conductive framework uses foamed nickel, an...

Embodiment 3

[0020] A nickel-metal hydride battery, the negative plate uses the AB5 hydrogen storage alloy powder produced by Zhuhai Jinfenghang Power Technology Co., Ltd., and the product model is 6S. The negative electrode conductive skeleton uses nickel mesh, and the negative electrode sheet is made by dry method of powdering. The negative electrode sheet is placed in 30% KOH solution, the solution temperature is 80°C, the negative electrode sheet is soaked for 25 hours, washed with water, and dried to obtain the surface layer. Negative sheet with nickel content of 68-80% within 0.5-3μm. The positive plate uses spherical nickel hydroxide produced by Henan Xinfei Kelong Power Supply Co., Ltd., and cobaltous oxide produced by Loudihong Sun Power New Material Co., Ltd. The positive conductive framework uses foamed nickel, and the positive plate is made by semi-dry method of powdering . The electrolyte uses 30% KOH solution. Assembled into a battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap