Permanent magnet motor

A technology of electric motors and permanent magnets, applied in the field of electric motors, can solve the problems of increased manufacturing errors, deterioration of yield, and dimensional tolerances, and achieve the effects of vibration, suppression of productivity reduction, and reduction of noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

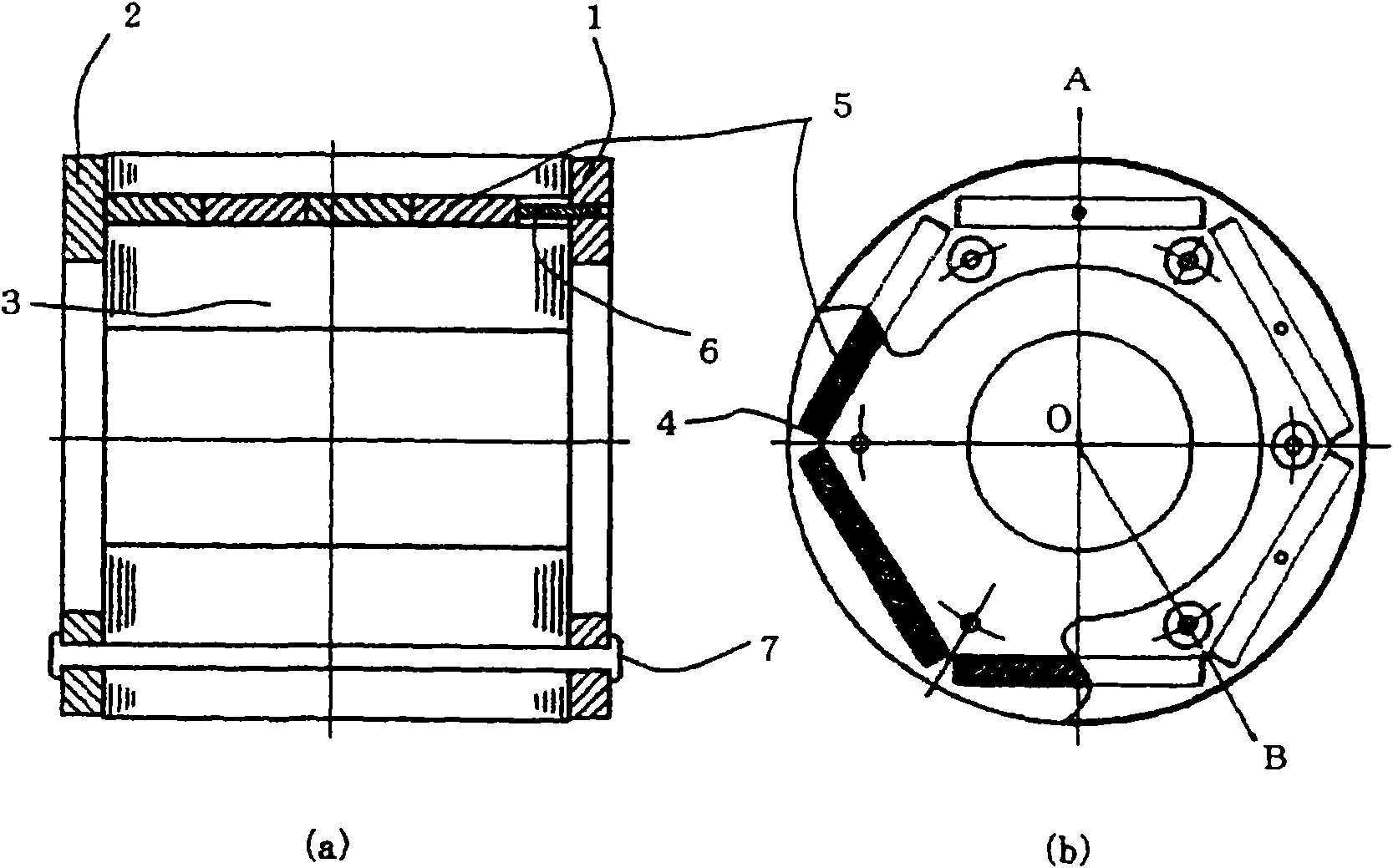

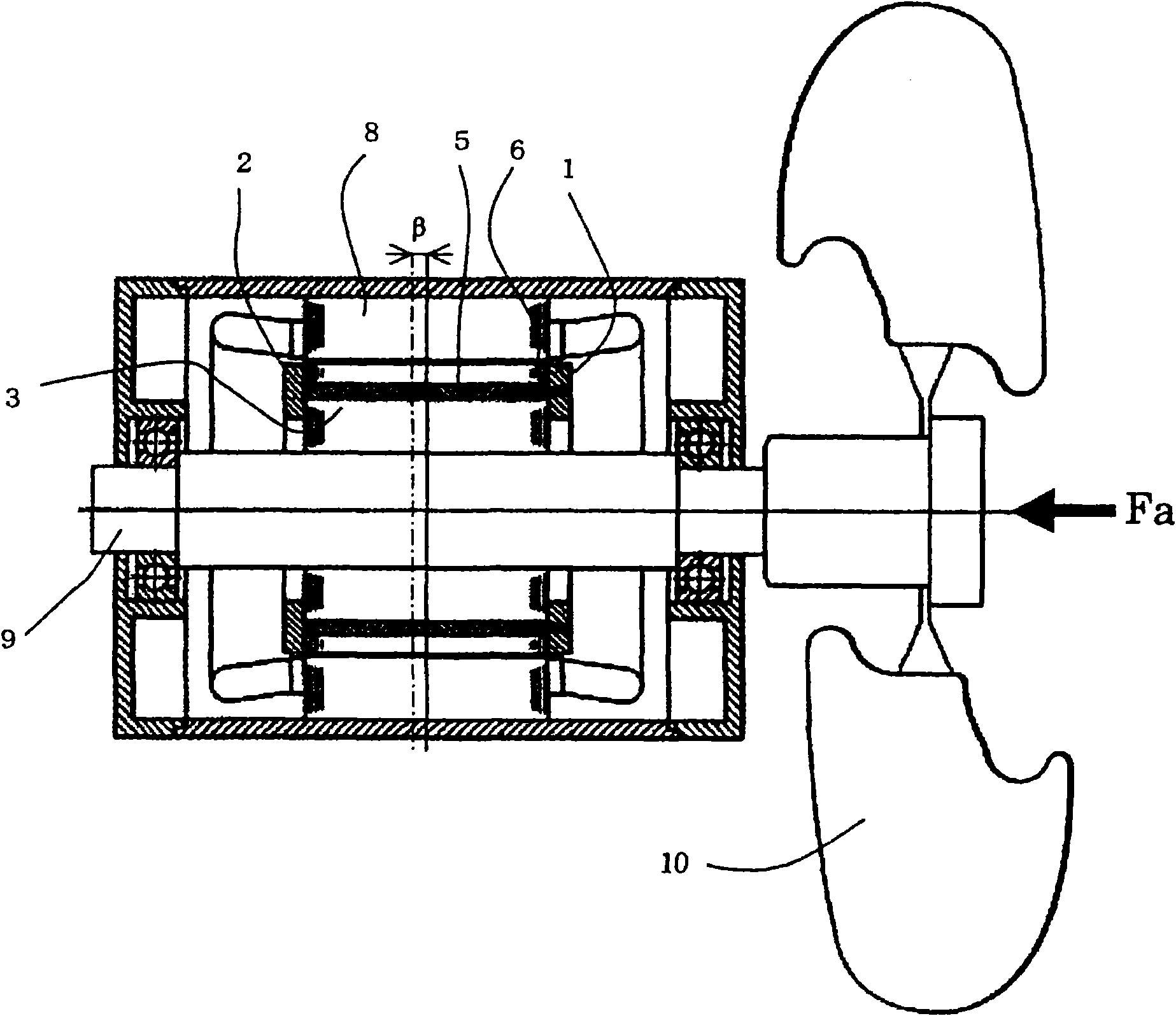

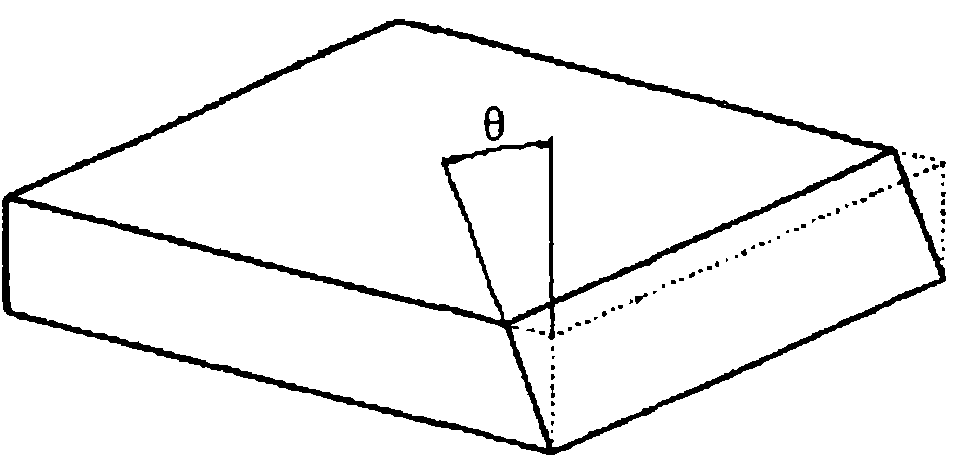

[0031] This embodiment relates to a motor (permanent magnet motor) provided with a permanent magnet inside a rotor, and discloses a configuration that not only improves production efficiency but also takes into account the usage of the motor. The IPM motor is generally configured such that slots are formed in a rotor core composed of laminated iron cores stacked in the direction of the rotation axis, and permanent magnets are arranged in the slots.

[0032] figure 1 It is a figure which shows the rotor of the electric motor of this embodiment. figure 1 (a) is a side sectional view of the rotor, figure 1 (b) is a front view seen from the direction of the rotation axis, and a part is shown in cross-section. figure 1 In (a), the auxiliary line extending left and right indicates the direction of the rotation axis, figure 1 The rotation center O shown in (b) corresponds to the direction of the rotation axis. also, figure 1 (a) is figure 1 (b) Cross-sectional view of line A-B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com