Method for operating a valve

A technology for operating valves and valve discs, applied in the direction of valve operation/release devices, valve fluid energy absorption devices, valve lifts, etc., can solve problems such as obstruction of free flow, friction loss, etc., and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

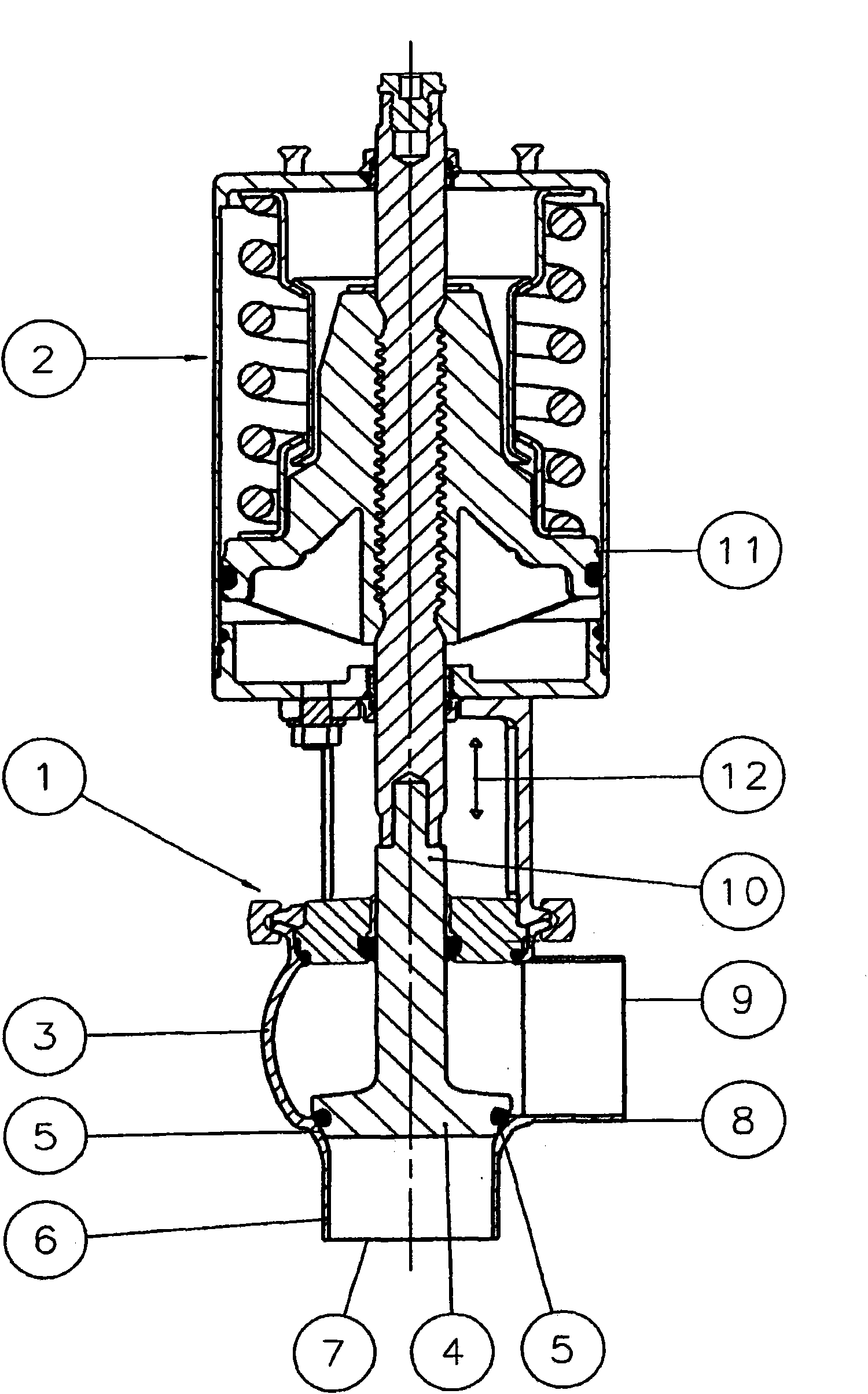

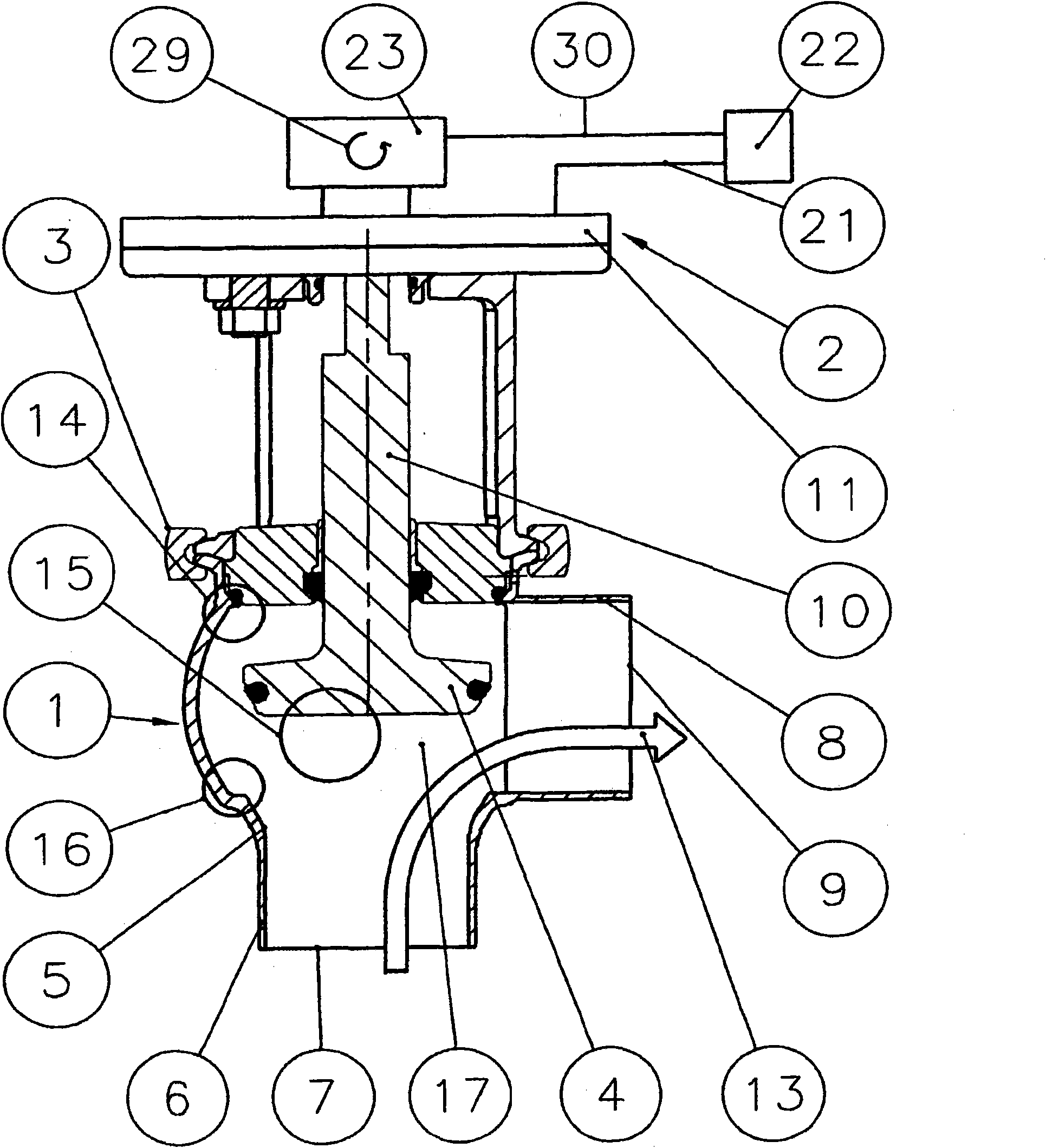

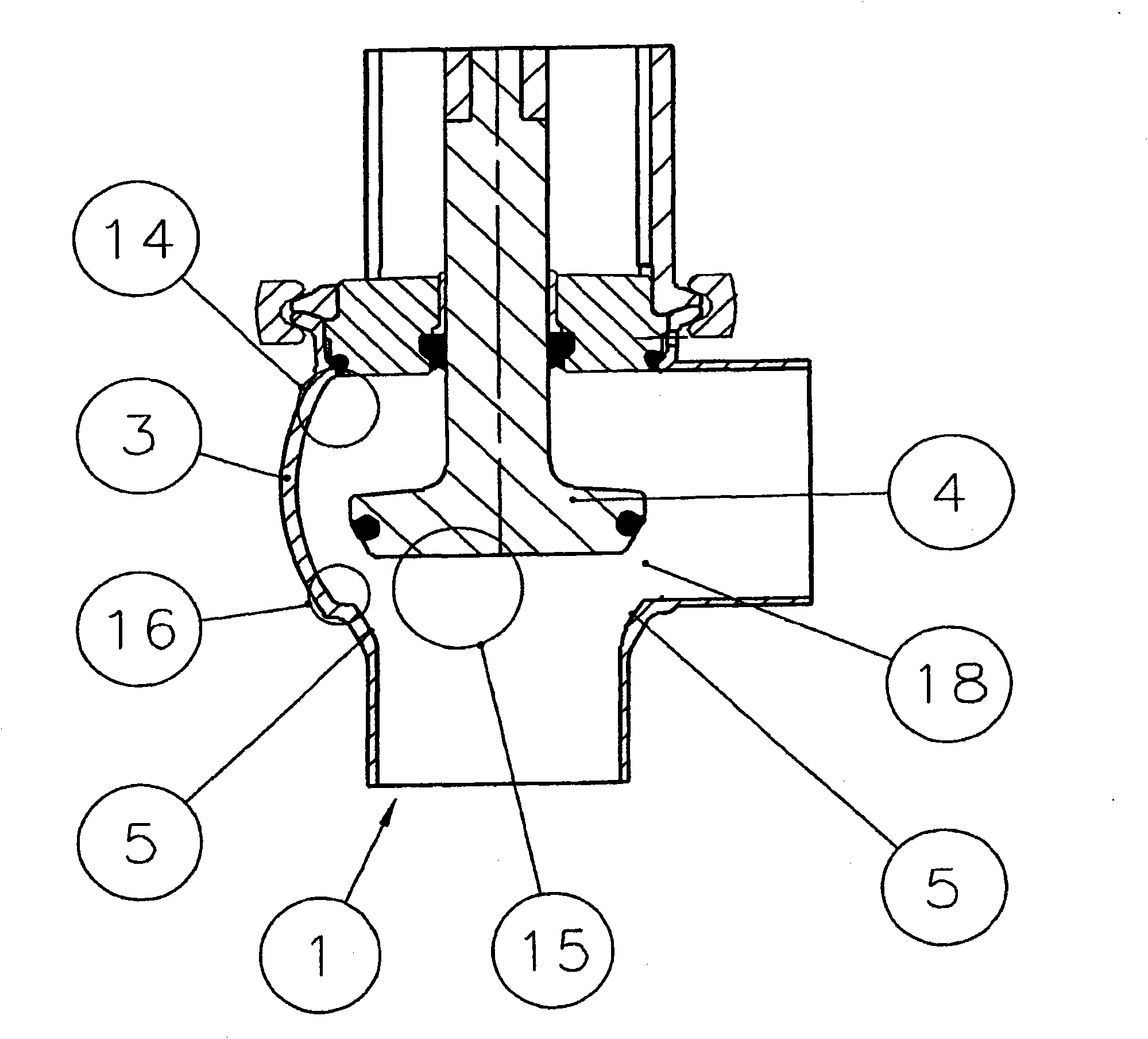

[0054] figure 1 The shown valve arrangement basically comprises a valve 1 and an actuating device 2 . The valve 1 has a valve housing 3 and a valve disc 4; in figure 1 In the closed position shown, the valve disc 4 is pressed against the valve seat 5 . The pipe connection 6 forms an inlet 7 of the valve through which fluid flows into the valve. The pipe connection 8 is arranged at right angles to the pipe connection 6 and serves as an outlet 9 from which the fluid is discharged. exist figure 1 In the closed state of the valve shown, no fluid can pass from the inlet 7 to the outlet 9 .

[0055] The valve disc 4 is connected to an actuating rod 10 which, for its part, is operatively connected to a pneumatic motor 11 of the actuating device 2 . The actuating rod 10 and thus the valve disk 4 can be moved up and down in the direction of the arrow 12 by means of the electric motor 11 . Due to moving down, such as figure 1 As shown, the valve disk 4 is pressed against the valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com