Bobbin sheet for fishing rod

A technology of spools and fishing rods, applied in fishing rods, applications, fishing, etc., can solve the problems of difficult operation and hard operation of pressing parts, and achieve the effect of easy operation and difficult plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

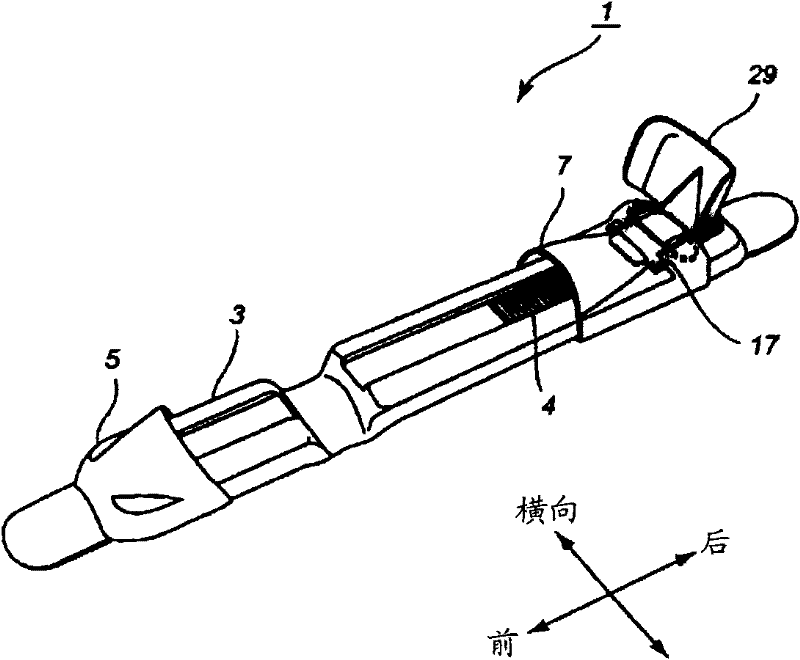

[0033] according to Figure 1 to Figure 6 The spool sheet 1 for a fishing rod according to the first embodiment of the present invention will be described.

[0034] First, follow the figure 1 The overall structure of the fishing rod spool piece 1 will be briefly described.

[0035] The spool piece 1 fixes the legs of the spool on the long rod body in the front-rear direction, including: a piece body 3 as a base for placing the legs and a pair of hat-shaped leg receiving parts 5 that receive and accommodate the ends of the legs on the piece body 3 , 7. The leg receiving openings of the leg receiving parts 5 and 7 are arranged in a state facing each other, one leg receiving part 5 is fixed, and the other leg receiving part 7 is attached to the sheet body 3 so as to be slidable. In order to fix the leg receiving portion 7 on the movable side with respect to the sheet body 3, a fixing mechanism is further provided.

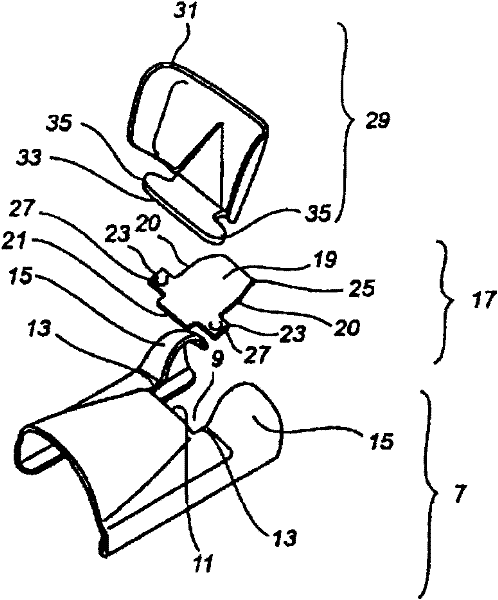

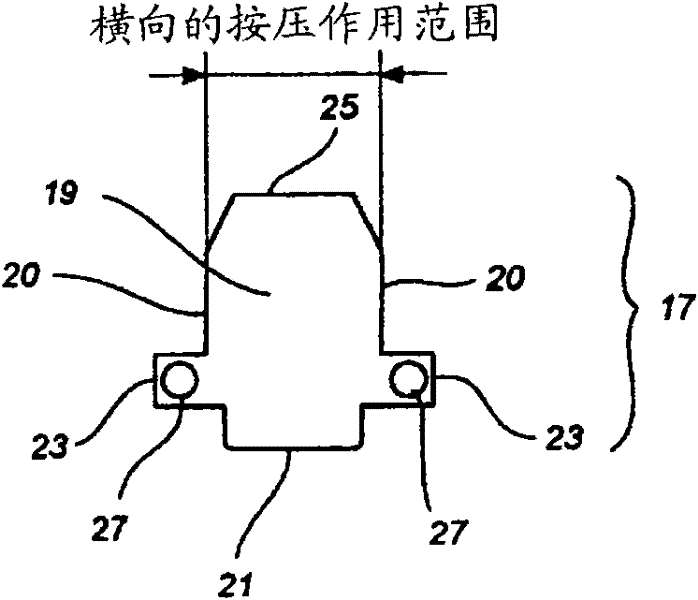

[0036] according to figure 2 , image 3 Describe the stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com