Plate shape control method with target of reducing maximum deviation

A technology of shape control and maximum deviation, applied in the direction of contour control, etc., can solve the problems of not considering the influence of the change of the maximum value of the shape of the shape, and cannot guarantee the quality requirements of the strip, etc., to achieve fast response and simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

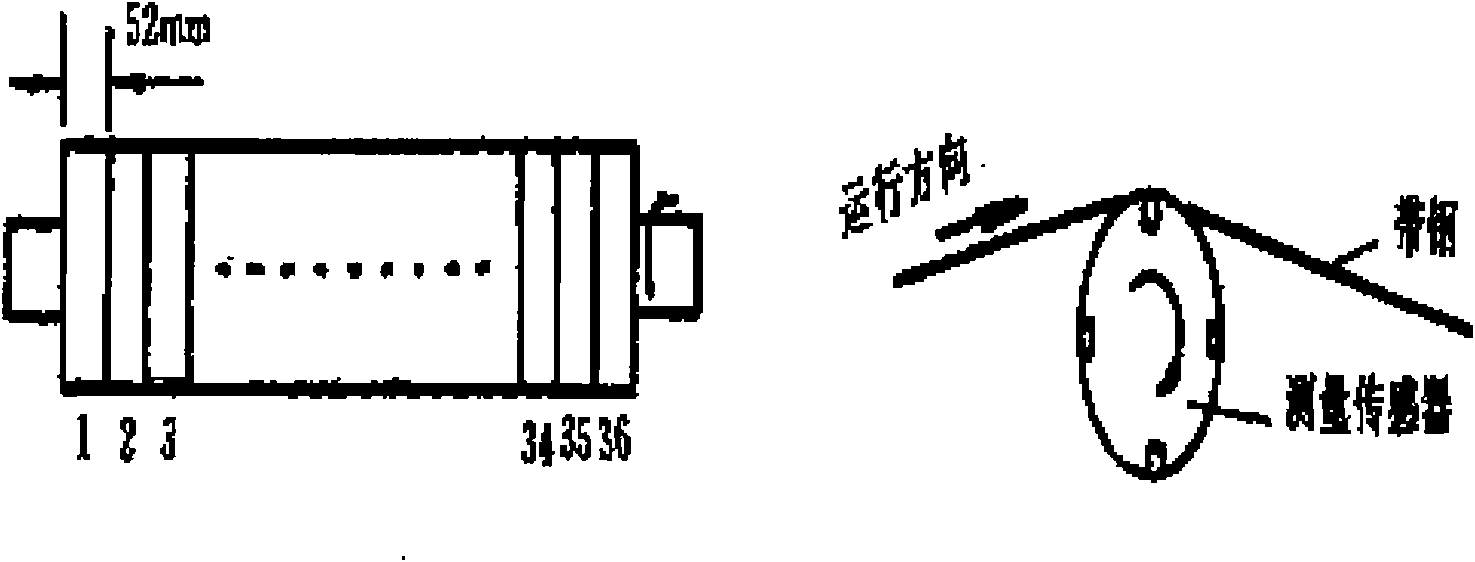

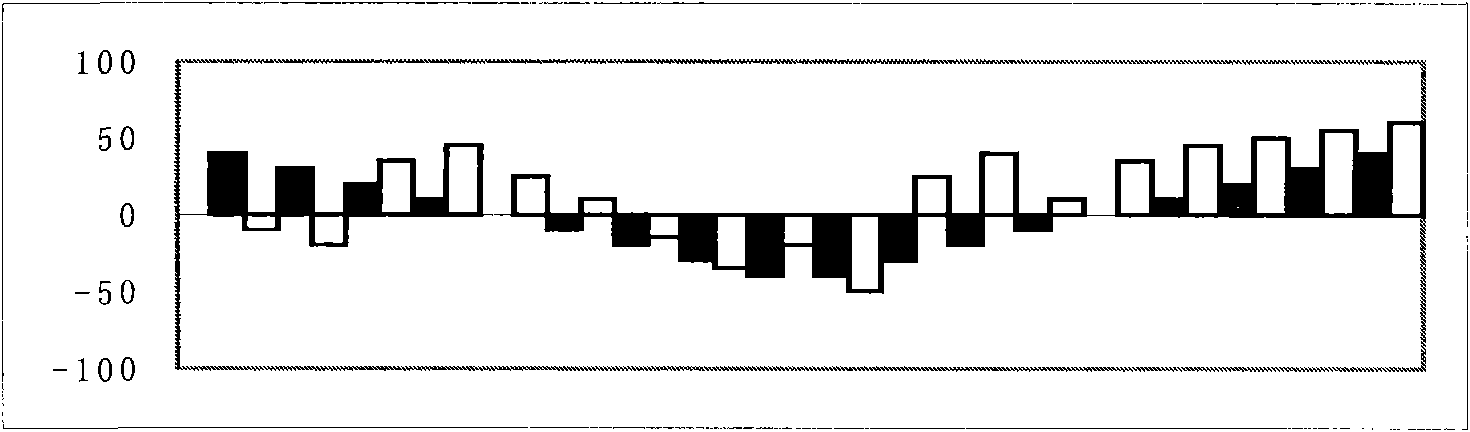

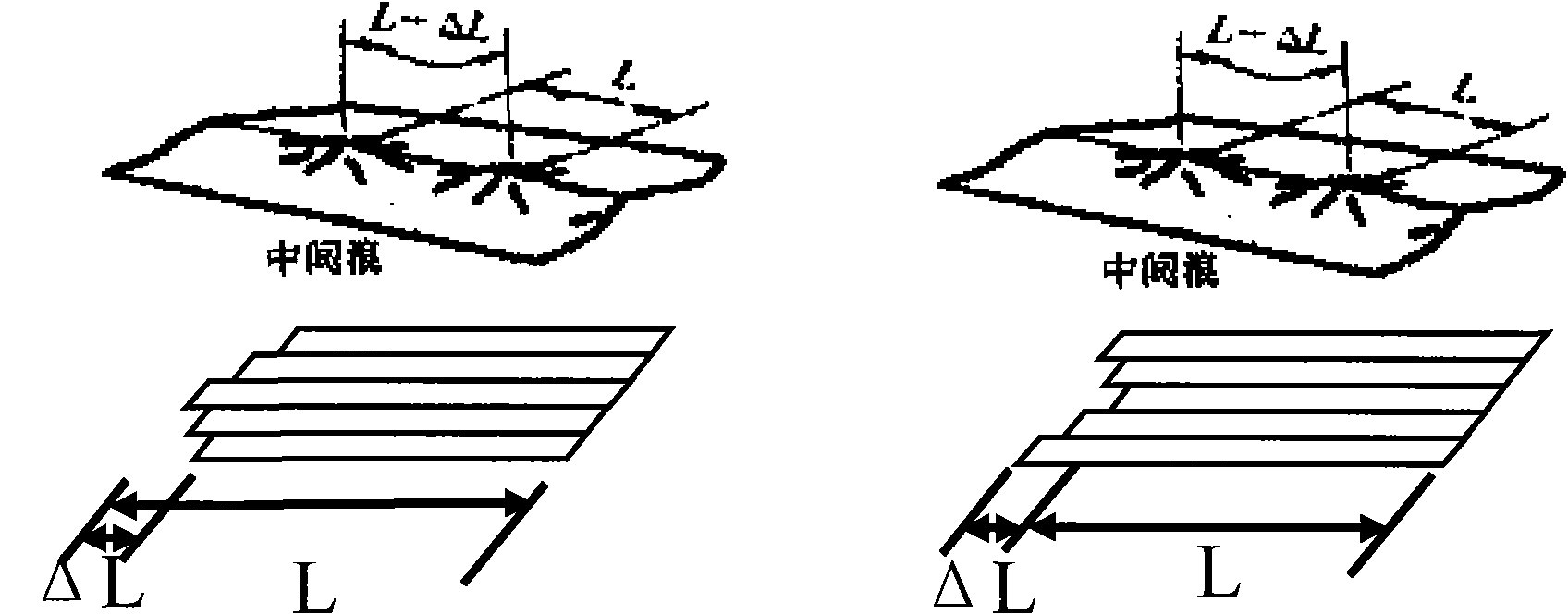

[0080] Example 1: Strip steel data: steel grade DU3542D1, entrance thickness 3.53mm, exit thickness 1.206mm, width 1781mm, according to the principle of strip correlation coefficient determination Bf=0.45, the maximum shape deviation is +23I, and it appears in the shape measurement The 17th ring of the instrument, according to the principle of determining the correlation coefficient of the maximum plate convexity deviation Df = 0.8, the pressure block pressure calculated according to the traditional control algorithm formula (1) is [162.52, 257.01, 175.39, 89.62, 121.79, 147.81, 259.17] .

[0081] (1) Calculate the position S0 from the middle of the strip to the maximum plate crown deviation according to formula 5

[0082] S 0 = Lr n * ( d - n 2 ) = 1872 36 * ( 17 - 36 2 ) = - 52 mm

[0083] (2) Calculate the briquette length according to formula 6

[0084] Wd = L M = 1925 7 = 275 mm

[008...

Embodiment 2

[0095] Example 2: Strip data: steel grade DT0144E1, entrance thickness 2.26mm, exit thickness 0.504mm, width 916mm, according to the strip correlation coefficient determination principle Bf = 0.25, the maximum shape deviation is +12I, and appear in the shape measurement The tenth ring of the instrument, according to the principle of determining the correlation coefficient of the maximum plate convexity deviation Df = 0.2, the pressure block pressure calculated according to the traditional control algorithm formula (1) is [23.4, 87.54, 106.46, 102.23, 97.52, 85.33, 19.9] .

[0096] (1) Calculate the position S0 from the middle of the strip to the maximum plate crown deviation according to formula 5

[0097] S 0 = Lr n * ( d - n 2 ) = 1872 36 * ( 10 - 36 2 ) = - 416 mm

[0098] (2) Calculate the briquette length according to formula 6

[0099] Wd = L M = 1925 7 = 275 mm

[0100] (3) Calculate...

Embodiment 3

[0112] Example 3: Strip steel data: steel grade AN0543D5, entrance thickness 3.02mm, exit thickness 0.797mm, width 1379mm, according to the strip correlation coefficient determination principle Bf=0.32, the maximum shape deviation is -15I, and it appears in the shape measurement In the 25th ring of the instrument, according to the principle of determining the correlation coefficient of the maximum plate crown deviation Df=0.48, the pressure block pressure calculated according to the traditional control algorithm formula (1) is [98.15, 114.68, 121.22, 153.54, 177.18, 137.78, 75.77] .

[0113] (1) Calculate the position S0 from the middle of the strip to the maximum plate crown deviation according to formula 5

[0114] S 0 = Lr n * ( d - n 2 ) = 1872 36 * ( 25 - 36 2 ) = 364 mm

[0115] (2) Calculate the briquette length according to formula 6

[0116] Wd = L M = 1925 7 = 275 mm

[0117] (3) Ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com