Saw board fixing device for gang saw welder

A fixing device and welding machine technology, which is applied in the field of machinery, can solve the problems of unsuitable fixing of welding machine gang saws, etc., and achieve the effect of flexible and stable moving saw board, stable lifting saw board, and easy control of the height of lifting saw board

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

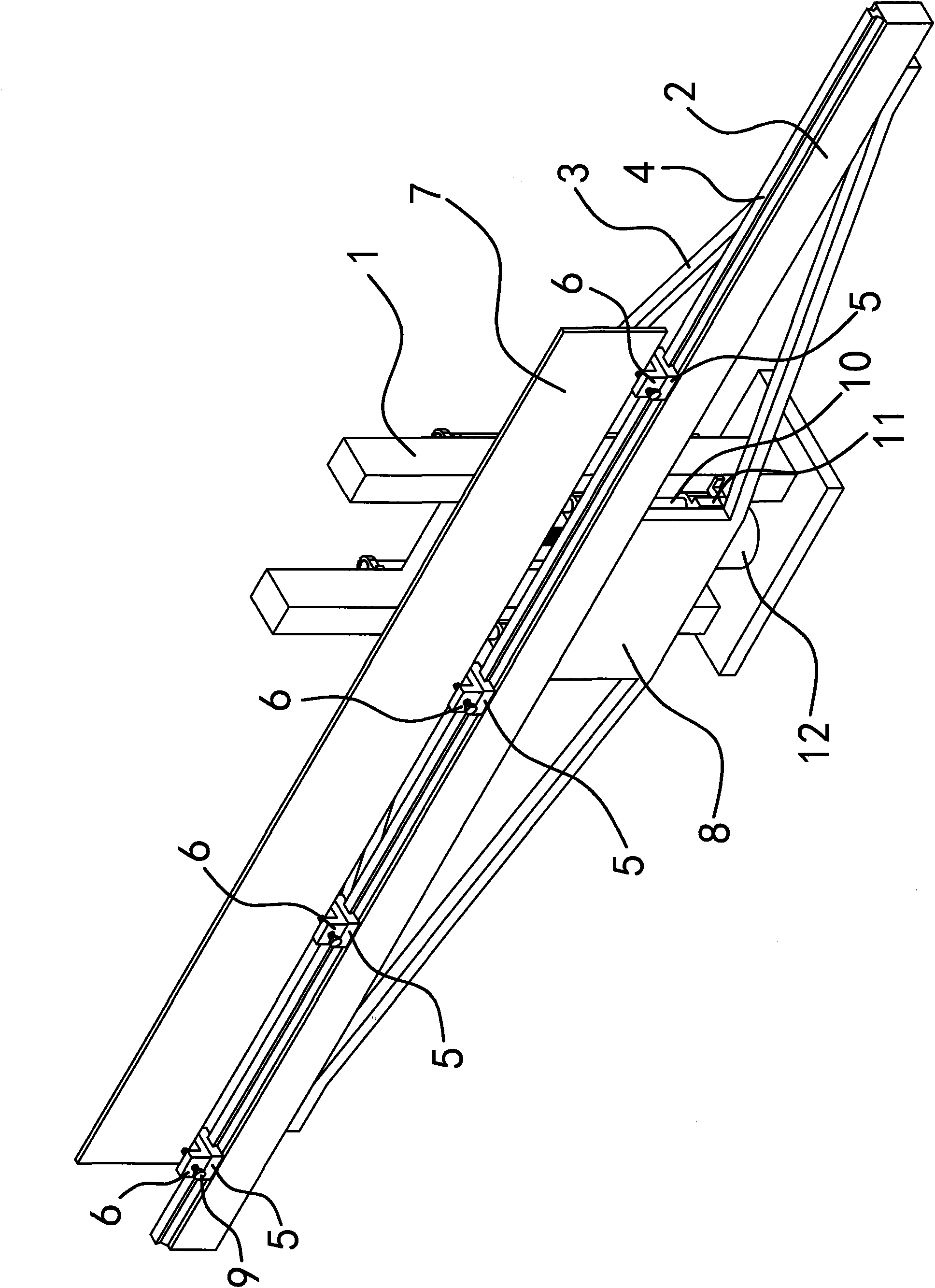

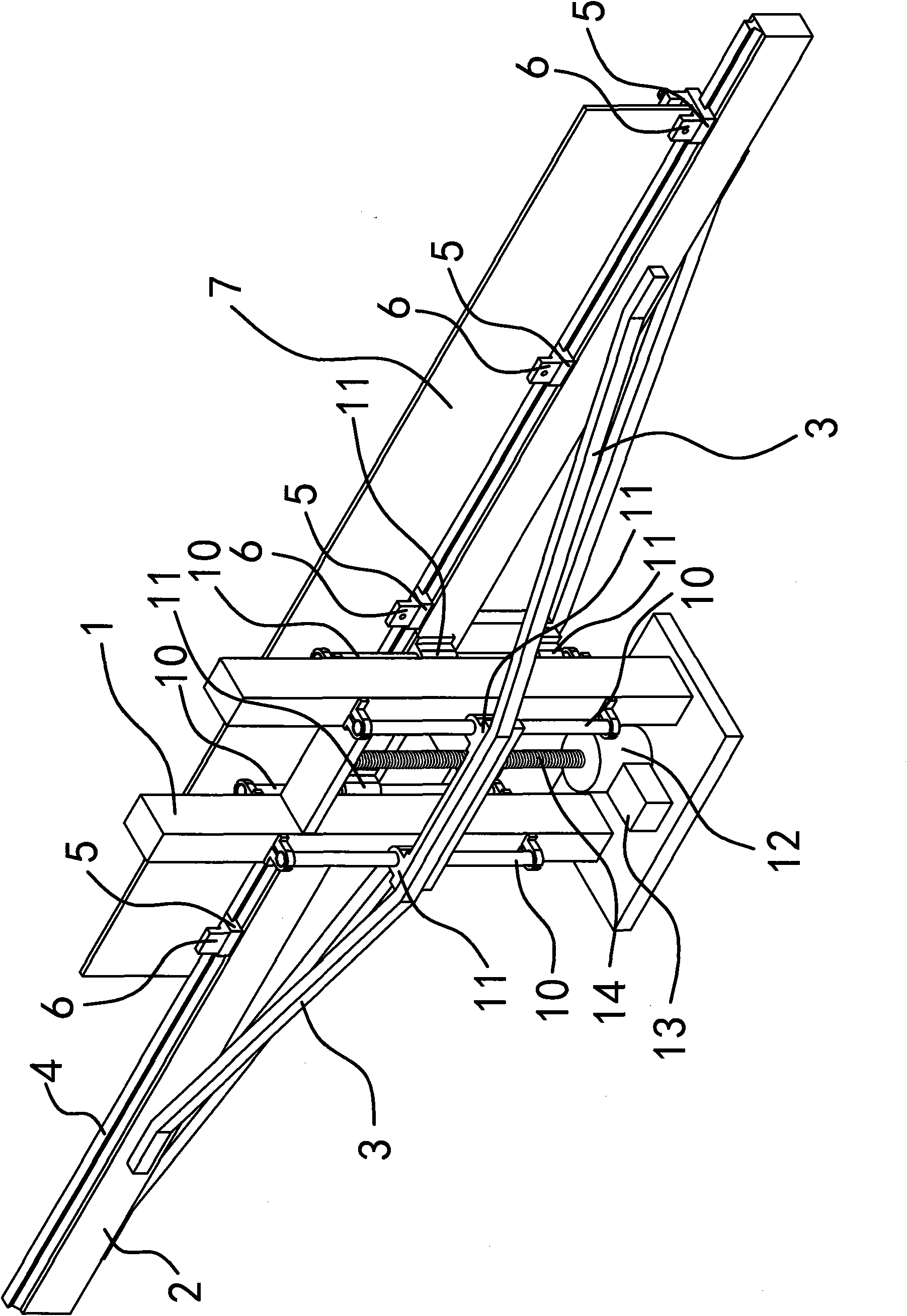

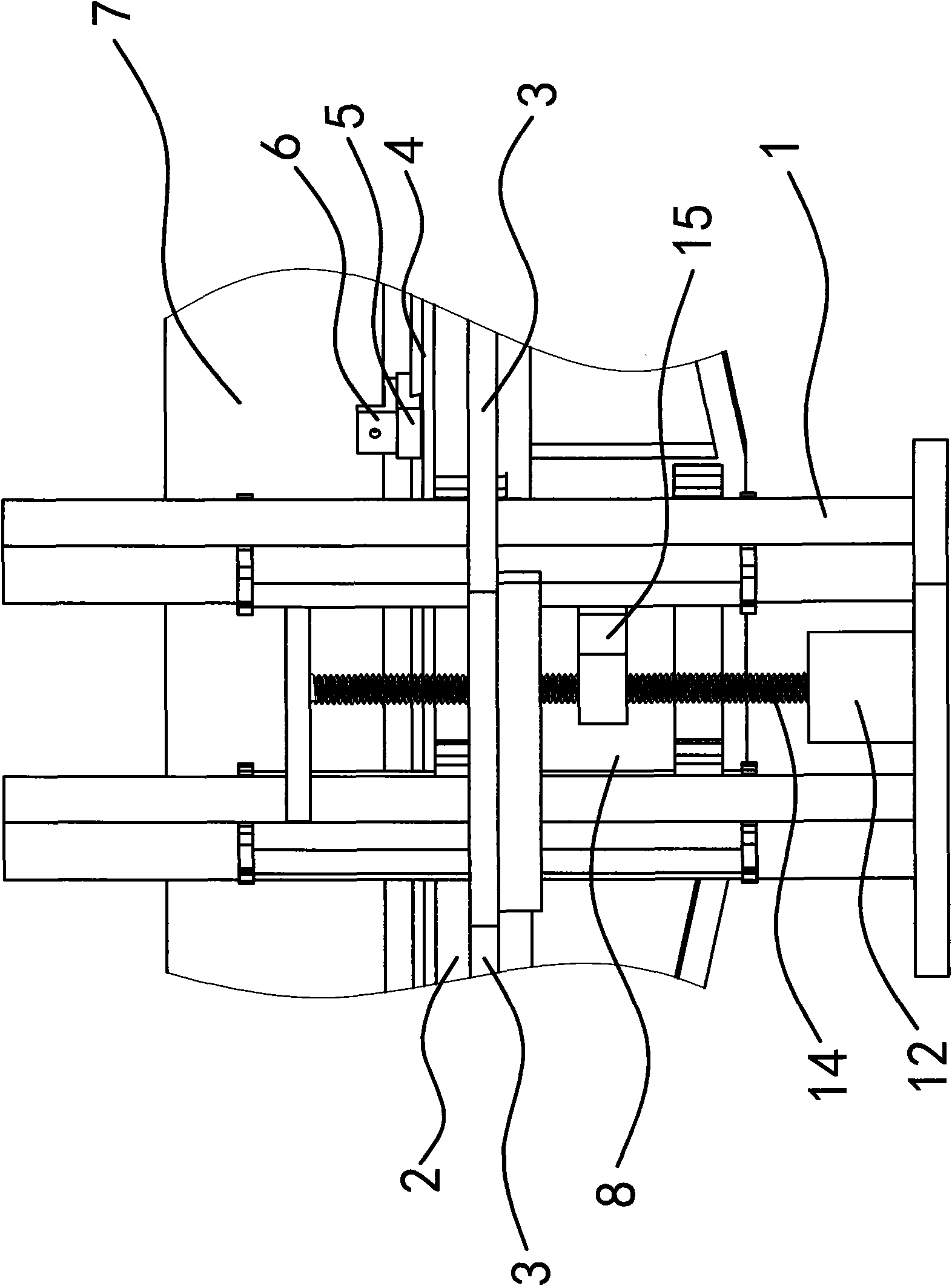

[0023] Specifically, as Figure 1 to Figure 4 As shown, the fixing frame 2 is welded by square tubes and is in the shape of a strip. The middle part of the fixed frame 2 is fixed with a fixed plate 8, and two groups of linear bearings 11 arranged side by side are fixed on the rear side of the fixed plate 8, and a guide rod 10 is pierced on each group of linear bearings 11. The end is fixed on the frame 1. The linear bearing 11 and the guide rod 10 cooperate to slide, and have the advantages of smooth movement, uniform force and guiding effect, thereby improving the stability of the vertical movement of the fixed frame 2 relative to the frame 1 .

[0024] Between the two sides of the frame 1 and the rear side of the fixed frame 2, a support rod 3 is arranged, one end of the support rod 3 is fixed at the end of the rear side of the fixed frame 2, and the other end of the support rod 3 extends to the rear of the frame 1 side and is fixed with a linear bearing 11, on the linear ...

Embodiment 2

[0031] The structure and principle of this embodiment are basically the same as that of Embodiment 1. The difference is that the driving mechanism includes a hydraulic cylinder and a hydraulic pump connected to the hydraulic cylinder. The cylinder body of the hydraulic cylinder is fixed on the frame 1, and the top of the piston rod is fixed. on mount 2. The hydraulic pump drives the piston rod of the hydraulic cylinder to go up and down, thereby driving the fixed frame 2 to go up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com