Wheel-leg combined type mobile robot platform

A mobile robot and composite technology, applied in the field of robots, can solve the problems of poor load capacity and endurance, high power consumption, low efficiency, etc., and achieve the effects of strong terrain adaptability, reduced energy consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Describe the present invention in detail below in conjunction with embodiment and accompanying drawing. The embodiments are carried out on the premise of the technical solutions of the present invention, and detailed implementation methods and processes are given. However, the protection scope of the claims of the present application is not limited to the description of the following embodiments.

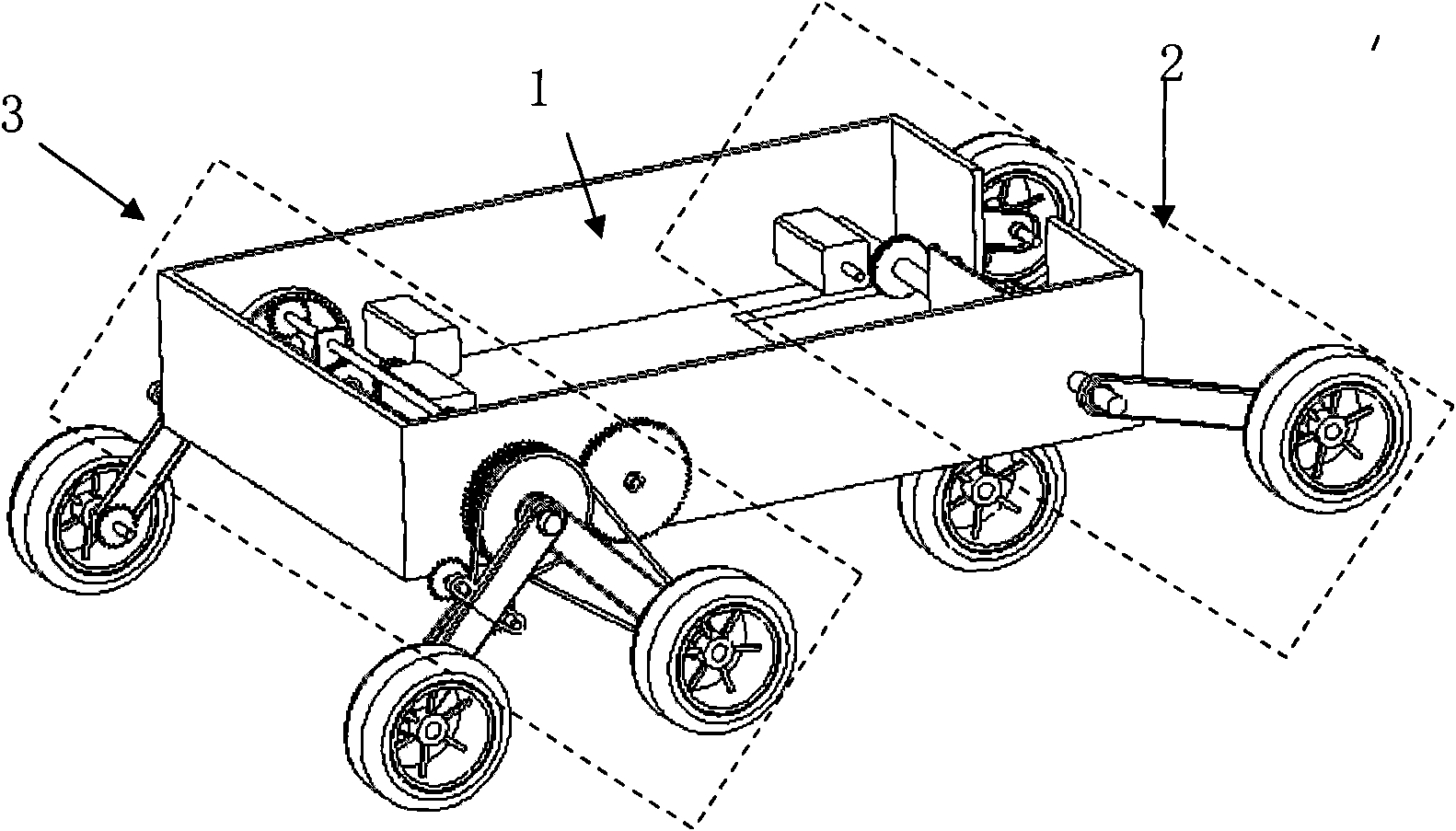

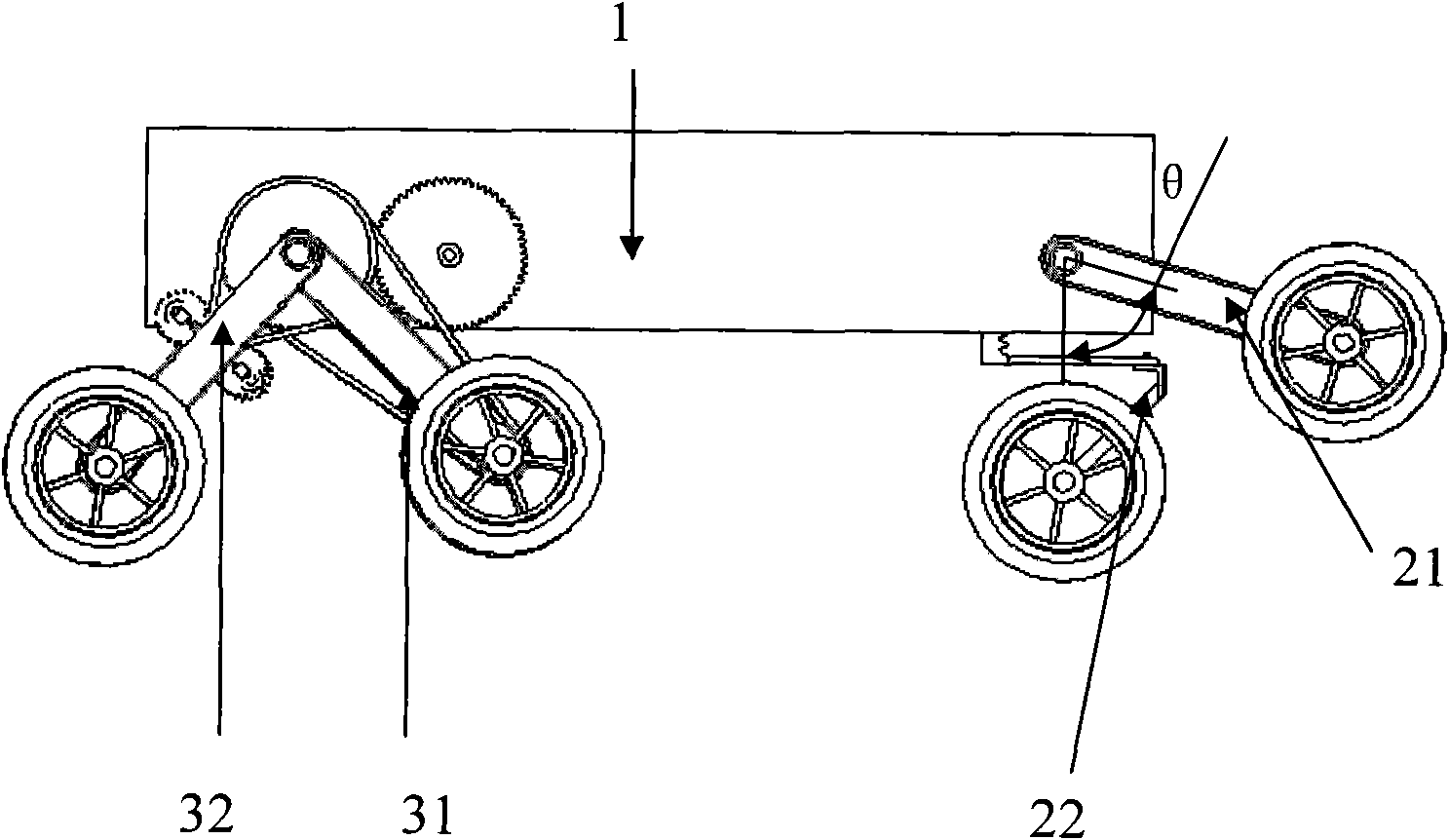

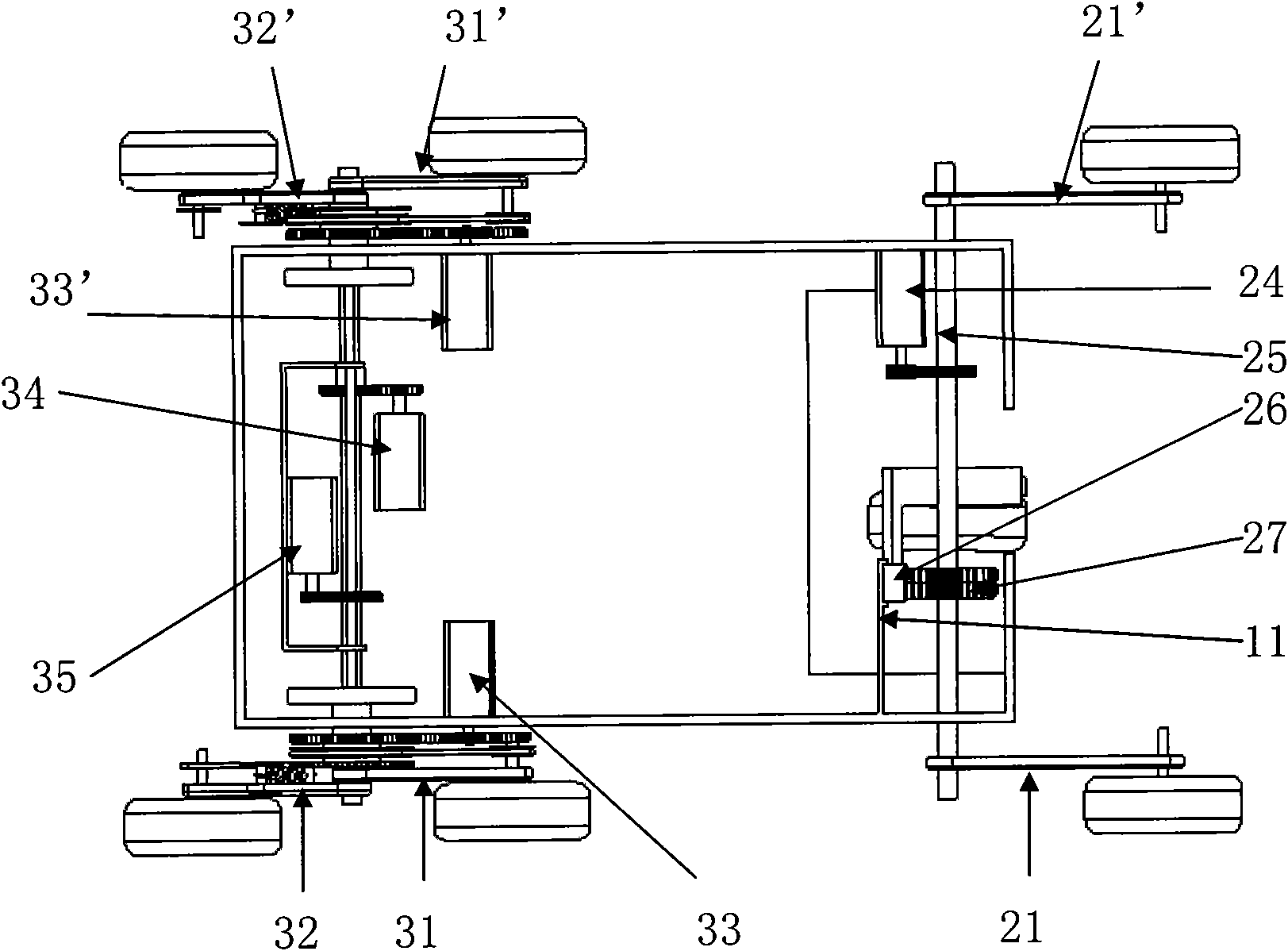

[0019] The wheel-leg compound mobile robot platform designed by the present invention (hereinafter referred to as the robot platform, see Figure 1-7 ) follows the modular design idea of the robot and adopts a modular design. The platform mainly includes a frame 1, a front leg module or system 2 and a rear leg module or system 3, and the rear leg module 2 includes a swing leg module or system and a drive module or The system has two subsystems. The front leg module 2 mainly adopts a rack and pinion structure (see Figure 4 ), the swing leg module mainly adopts a sleeve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com