Ultrasonic metal surface processing device used for processing plane on milling machine or boring machine

A technology of metal surface and processing device, applied in the field of ultrasonic metal surface processing device, can solve problems such as no practical application or report, achieve the best processing effect, solve the problem of rotation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

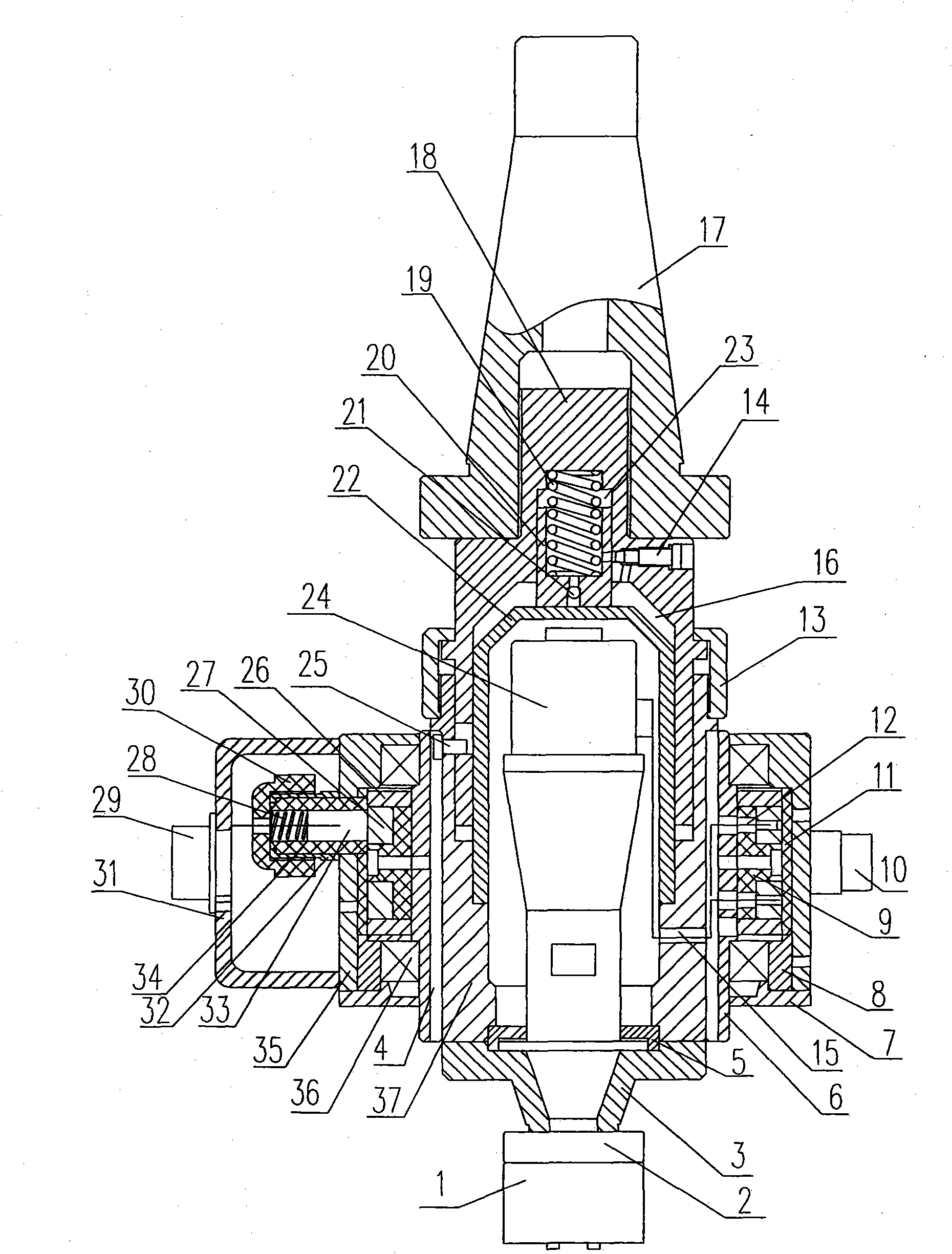

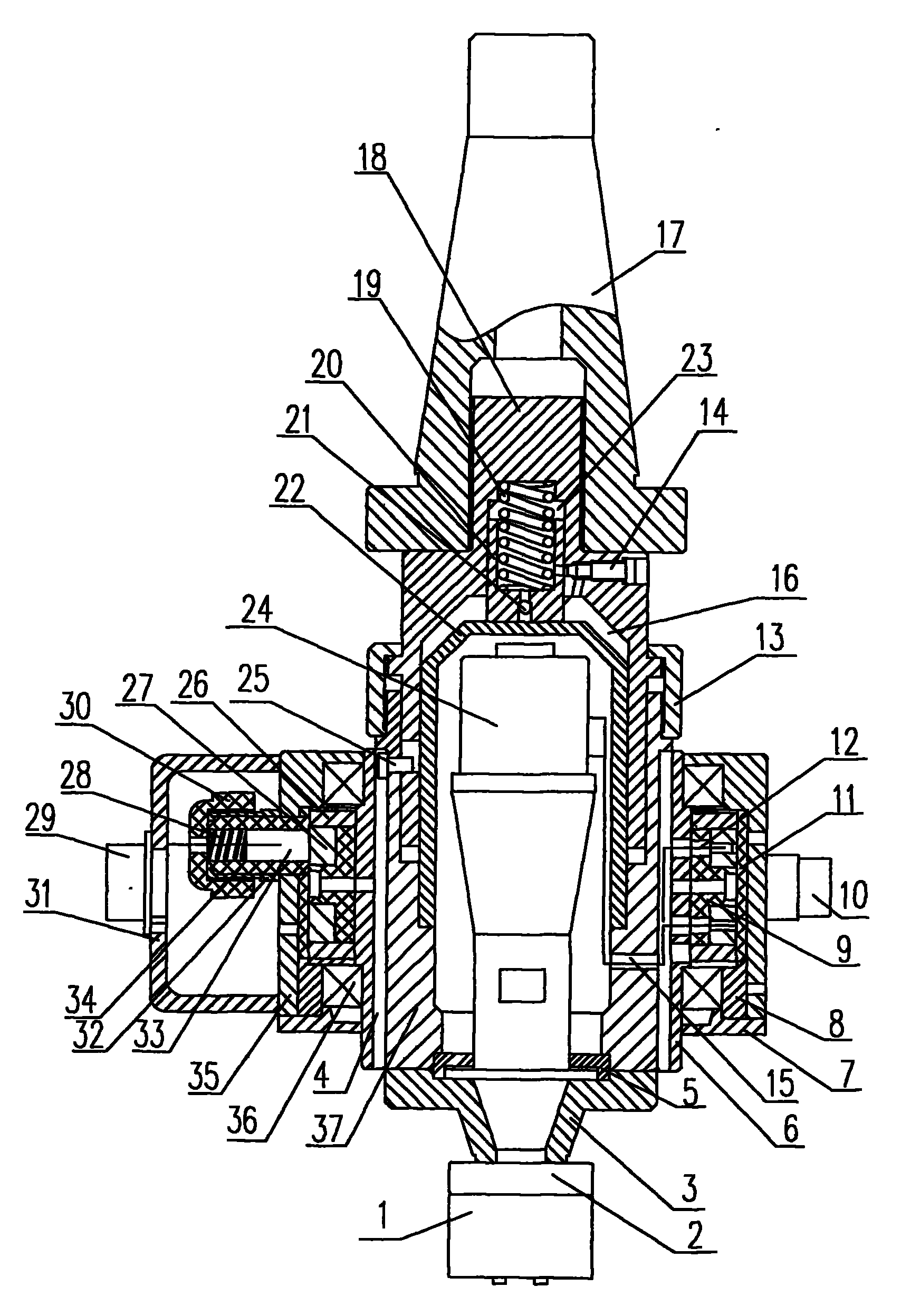

[0014] Such as figure 1 As shown, the ultrasonic metal surface processing device for milling machine or boring machine of the present invention mainly includes a taper shank 17, a collet 18, a housing 37, a transducer horn 24, a force stabilizing device and a rotating circuit device.

[0015] Chuck 18 is threaded on the lower end of taper shank 17 (the top and bottom of the position indicated in the full text are figure 1 The position determination shown in ), the housing 37 is set on the lower part of the chuck 18, and the outer circle of the chuck 18 is provided with a positioning flange and a connecting nut 13, and the positioning flange and the connecting nut 13 are used for the housing 37 movement limit on chuck 18. The upper part of the housing 37 is threadedly connected with the connecting nut 13 on the collet 18, and is limited by the positioning flange. The housing 37 is provided with a positioning pin 25 , and the positioning pin 25 is inserted into a limiting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com